5901 Botham Jean Blvd, Dallas, TX 75215

Is Nickel Magnetic? Unveiling the Truth About This Essential Metal

June 7, 2025Nickel is magnetic and belongs to a small group of elements with ferromagnetic properties at room temperature. When placed near a magnet, nickel experiences a strong attraction, setting it apart from most other metals on the periodic table.

Nickel’s magnetism arises from its atomic structure. Nickel atoms have unpaired electrons in their 3d orbitals, creating small magnetic fields that, when aligned, produce a significant magnetic effect. Each nickel atom acts as a tiny magnet with its own north and south pole. When these atomic magnets align, the material responds strongly to external magnetic fields.

Nickel’s magnetic properties are crucial in various industries. From electronics and data storage to renewable energy systems and medical devices, nickel’s unique behavior supports technologies we depend on daily. Understanding nickel’s interaction with magnetic fields helps us utilize this versatile metal in our technology-driven world.

What Makes Nickel Magnetic at the Atomic Level?

Nickel’s magnetic behavior arises from its unique atomic structure. At the core of this phenomenon is nickel’s electron configuration: [Ar] 3d⁸ 4s². This setup includes eight electrons in the 3d orbital, with two of these electrons unpaired. These unpaired electrons are the source of nickel’s magnetic properties.

When electrons pair, their opposing spins cancel out any magnetic effect. However, unpaired electrons create small magnetic fields known as magnetic moments. In nickel, these unpaired electrons in the 3d orbital produce magnetic moments that can align with external magnetic fields, resulting in the magnetic attraction observed in everyday life.

The crystalline structure of nickel is also critical to its magnetic behavior. Nickel atoms form a face-centered cubic (FCC) structure. This arrangement creates favorable conditions for the exchange interaction, a quantum mechanical effect where neighboring atoms’ magnetic moments influence each other to align in the same direction.

Magnetic Domains: The Building Blocks of Magnetism

Within nickel, these aligned magnetic moments form regions called magnetic domains. Each domain contains billions of atoms with their magnetic moments aligned. In an unmagnetized piece of nickel, these domains are randomly oriented, effectively canceling each other out.

When an external magnetic field is applied, the domains aligned with the field grow at the expense of those oriented differently. The boundaries between domains, known as domain walls, shift and move. As the external field strengthens, more domains align until the material reaches magnetic saturation, where all domains point in the same direction.

Temperature significantly impacts this domain behavior. Below its Curie temperature of approximately 358°C (676°F), nickel retains its ferromagnetic properties. Above this temperature, thermal energy disrupts the alignment of the magnetic moments, and nickel becomes paramagnetic, exhibiting only weak magnetic properties.

Exchange Interaction: The Force Behind Alignment

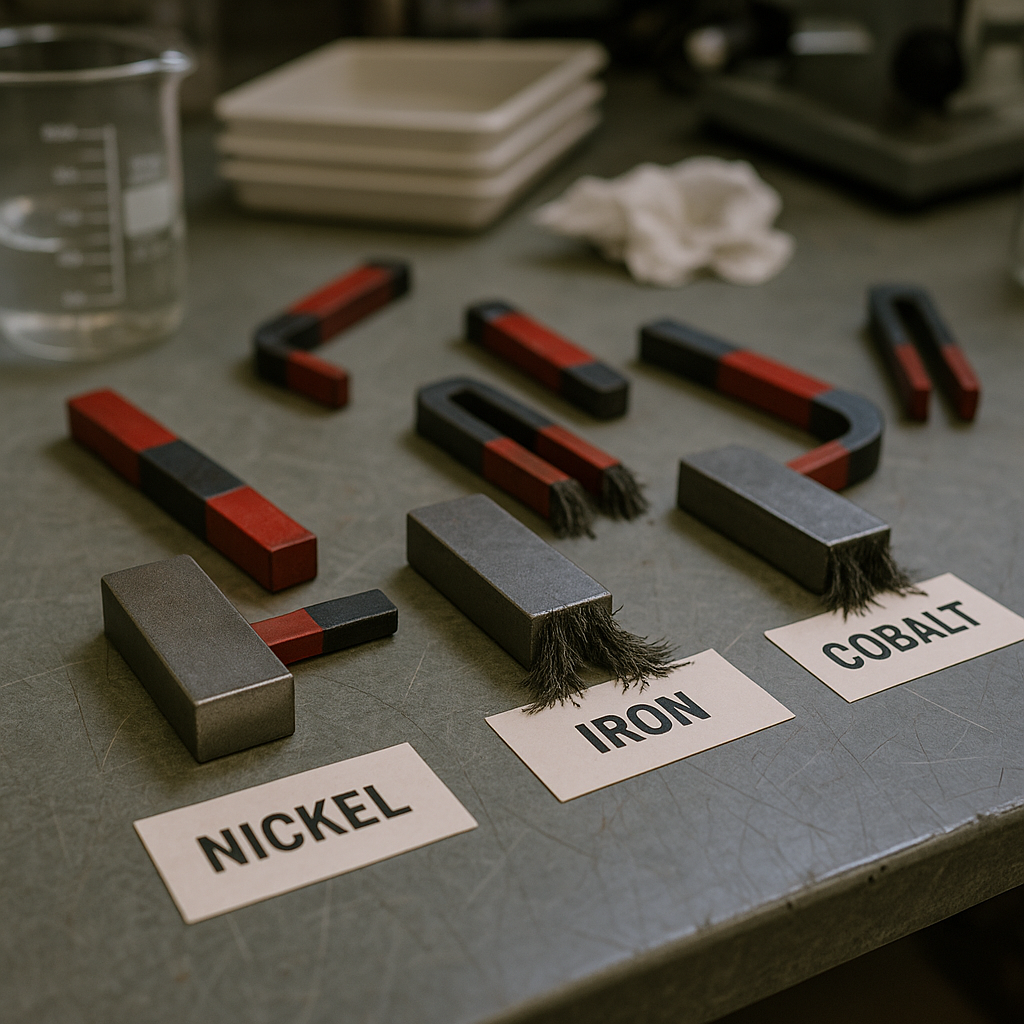

The exchange interaction between neighboring atoms in nickel creates a strong internal field that maintains the alignment of magnetic moments within domains. This quantum mechanical effect results from the overlap of electron wavefunctions between adjacent atoms. The strength of this effect in nickel makes it one of only three elements (along with iron and cobalt) that display strong ferromagnetism at room temperature.

This atomic-level magnetic behavior has significant implications for nickel’s applications in technology. Its stable magnetic properties make it valuable for electronics, data storage devices, and various magnetic alloys. Understanding these microscopic mechanisms helps engineers develop better magnetic materials for modern applications.

The combination of unpaired electrons, favorable crystal structure, and strong exchange interactions makes nickel an important ferromagnetic material with magnetic properties that can be harnessed for numerous practical applications.

[[artifact_table]] Comparison of Key Magnetic Properties of Nickel vs. Other Ferromagnetic Elements [[/artifact_table]]How Does Nickel Compare to Other Magnetic Metals?

Nickel stands apart from its ferromagnetic counterparts with a unique magnetic profile. As a member of the iron triad with iron and cobalt, nickel’s magnetic properties make it valuable for specific applications while limiting its use in others.

The magnetic saturation of nickel is notably lower than that of iron, meaning nickel reaches its maximum magnetization at a lower threshold. However, nickel compensates with higher magnetic permeability in certain configurations, allowing it to develop magnetic flux more readily in some applications.

Curie Temperature Differences

One significant distinction between these magnetic metals is their Curie temperature, marking the point at which a material loses its ferromagnetic properties due to thermal agitation.

Nickel has a relatively low Curie temperature of approximately 354°C (627K), while iron maintains its magnetic properties up to 768°C (1043K). Cobalt demonstrates the highest thermal stability, retaining magnetism until 1121°C (1394K).

These temperature differences impact which metal works best in high-temperature environments. Industries requiring components to maintain magnetic properties at elevated temperatures typically favor cobalt over nickel.

[[artifact_table]] Comparison of Magnetic Properties: Nickel, Iron, and Cobalt [[/artifact_table]]Permeability Characteristics

The magnetic permeability of these metals varies significantly across different alloy compositions. Pure iron can achieve remarkably high relative permeability values up to 200,000, making it exceptionally responsive to external magnetic fields.

Nickel shows more moderate permeability ranges between 100-600, making it less magnetically responsive than iron but still valuable in many applications. The permeability characteristics change dramatically when these metals combine in alloys.

Adding even small amounts of nickel or cobalt to iron (around 10%) can reduce maximum permeability by as much as 85%. This relationship illustrates how precisely engineers can tune magnetic properties by adjusting alloy compositions.

Practical Applications of Different Magnetic Metals

These varying magnetic properties translate directly to specialized industrial applications. Iron-nickel alloys with nickel content between 35% and 85% exhibit unique magnetic behaviors suitable for specific uses.

Nickel’s moderate magnetic strength combined with superior corrosion resistance makes it invaluable in marine environments. Its lower Curie temperature also provides opportunities in temperature-sensing applications and thermal safety systems.

Cobalt alloys excel in high-temperature contexts where maintaining magnetic properties is critical. The exceptional permeability of iron makes it the preferred material for transformers and other applications requiring high magnetic flux density.

By understanding these comparative properties, manufacturers can select the optimal magnetic material for each specific application. This knowledge is essential when designing components for extreme environments or specialized electronic systems.

What Are the Practical Applications of Nickel’s Magnetic Properties?

Nickel’s unique magnetic characteristics make it an invaluable material in various industrial and technological applications. Its ferromagnetic nature at room temperature allows it to generate and maintain magnetic fields, creating opportunities for use across multiple sectors. Let’s explore how nickel’s magnetic properties are harnessed in practical applications.

Magnetic Alloys in Power Generation and Motion

Nickel serves as a fundamental component in several magnetic alloys used in the energy sector. When combined with iron, nickel forms Permalloy, which exhibits high magnetic permeability and low coercivity. These properties make it ideal for transformer cores where efficient energy transfer is essential.

In motor and generator construction, Alnico magnets containing aluminum, nickel, and cobalt provide strong, temperature-stable magnetic fields. These magnets power everything from small electric motors in household appliances to larger generators in wind turbines. The stability of nickel-containing magnets at varying temperatures ensures consistent performance even under demanding conditions.

Nickel-iron alloys are also crucial in electromagnetic relays, which are switching devices used in power distribution systems. The precise magnetic response of these alloys allows for reliable operation in these critical infrastructure components.

Magnetic Shielding Applications

Nickel alloys excel at magnetic shielding due to their high magnetic permeability. In sensitive electronic equipment, Mu-metal (containing about 80% nickel) creates barriers that protect devices from external magnetic interference. This application is vital in laboratories where precise measurements could be disrupted by ambient magnetic fields.

Medical equipment benefits significantly from nickel’s shielding capabilities. MRI machines rely on proper magnetic field containment to produce accurate diagnostic images. The shielding prevents external magnetic influences from distorting these critical medical scans, improving diagnostic accuracy.

Data centers also utilize nickel alloys in shielding applications to protect storage devices from magnetic interference. This protection ensures data integrity and prevents potential corruption caused by stray magnetic fields.

Energy Storage and Battery Technology

Nickel plays a critical role in rechargeable battery technology. Nickel-metal hydride (NiMH) batteries leverage nickel’s magnetic and chemical properties to store and release energy efficiently. These batteries power many consumer electronics and hybrid vehicles.

In nickel-cadmium (NiCd) batteries, nickel hydroxide serves as the positive electrode. Though less common today due to environmental concerns about cadmium, these batteries were valued for their reliability in power tools and emergency lighting systems.

The emerging lithium-nickel-manganese-cobalt (NMC) batteries used in electric vehicles also benefit from nickel’s properties. These batteries offer improved energy density and performance, helping extend the range of electric vehicles.

Electronic Components and Data Storage

The electronics industry relies heavily on nickel’s magnetic characteristics. Magnetic sensors containing nickel detect changes in magnetic fields, enabling applications ranging from automotive speed sensors to security systems. These sensors provide crucial data for control systems in modern vehicles and industrial equipment.

Data storage technology has historically depended on magnetic recording media containing nickel alloys. Hard drives use thin films of nickel alloys to store data magnetically. Though solid-state storage is increasingly common, magnetic storage remains important for archival purposes and high-capacity applications.

Nickel is also essential in manufacturing read/write heads for magnetic storage devices. These precision components require materials with specific magnetic properties to function effectively.

Medical and Scientific Applications

In the medical field, nickel’s magnetic properties contribute to diagnostic and treatment technologies. Beyond MRI machines, nickel alloys appear in various medical devices that require reliable magnetic response, such as magnetic separation equipment used in laboratory settings.

Scientific research instruments often contain nickel components in their magnetic systems. Mass spectrometers, particle accelerators, and other advanced research tools utilize nickel’s reliable magnetic characteristics to control particle beams and enable precise measurements.

The biomedical field uses magnetic nickel nanoparticles for targeted drug delivery. These tiny particles can be guided through the body using external magnetic fields, potentially improving treatment efficacy while reducing side effects.

Industrial Sensing and Control

Industrial automation relies significantly on magnetic sensing technologies. Nickel-based sensors detect position, proximity, and speed in manufacturing equipment. These sensors enable precise control of robotic systems and production lines, improving efficiency and product quality.

Flow meters using magnetic principles often contain nickel components. These devices accurately measure liquid flow rates in pipelines and industrial processes, providing critical data for process control and optimization.

In the automotive industry, nickel-containing magnetic sensors monitor everything from crankshaft position to wheel speed. These sensors feed essential information to vehicle control systems, enhancing both performance and safety features.

As industries continue to evolve, nickel’s magnetic properties will likely find new applications in emerging technologies. From renewable energy systems to advanced computing, the versatility of nickel ensures its continued relevance in addressing technological challenges and creating innovative solutions.

Conclusion: The Enduring Significance of Nickel’s Magnetism

Nickel is one of only three elements that exhibit ferromagnetism at room temperature, making it essential in numerous technological applications. Its magnetic properties arise from its unique atomic structure, where unpaired electrons in its 3d orbital create an ideal environment for magnetic behavior. This characteristic allows nickel to enhance transformer cores and medical devices by forming specialized alloys with tailored magnetic properties.

The versatility of nickel’s magnetism continues to drive innovation across various industries. From permanent magnets in electric motors to magnetic recording media in data storage systems, nickel’s unique capabilities advance technology in ways that affect our daily lives. As research progresses in manipulating and optimizing nickel’s magnetic properties through alloying and processing techniques, we can expect even more groundbreaking applications for this remarkable metal. For professional guidance on recycling nickel-containing materials and contributing to the sustainable use of this valuable resource, contact Okon Recycling at 214-717-4083.