5901 Botham Jean Blvd, Dallas, TX 75215

Types of Metal: Exploring the Different Types of Metal?

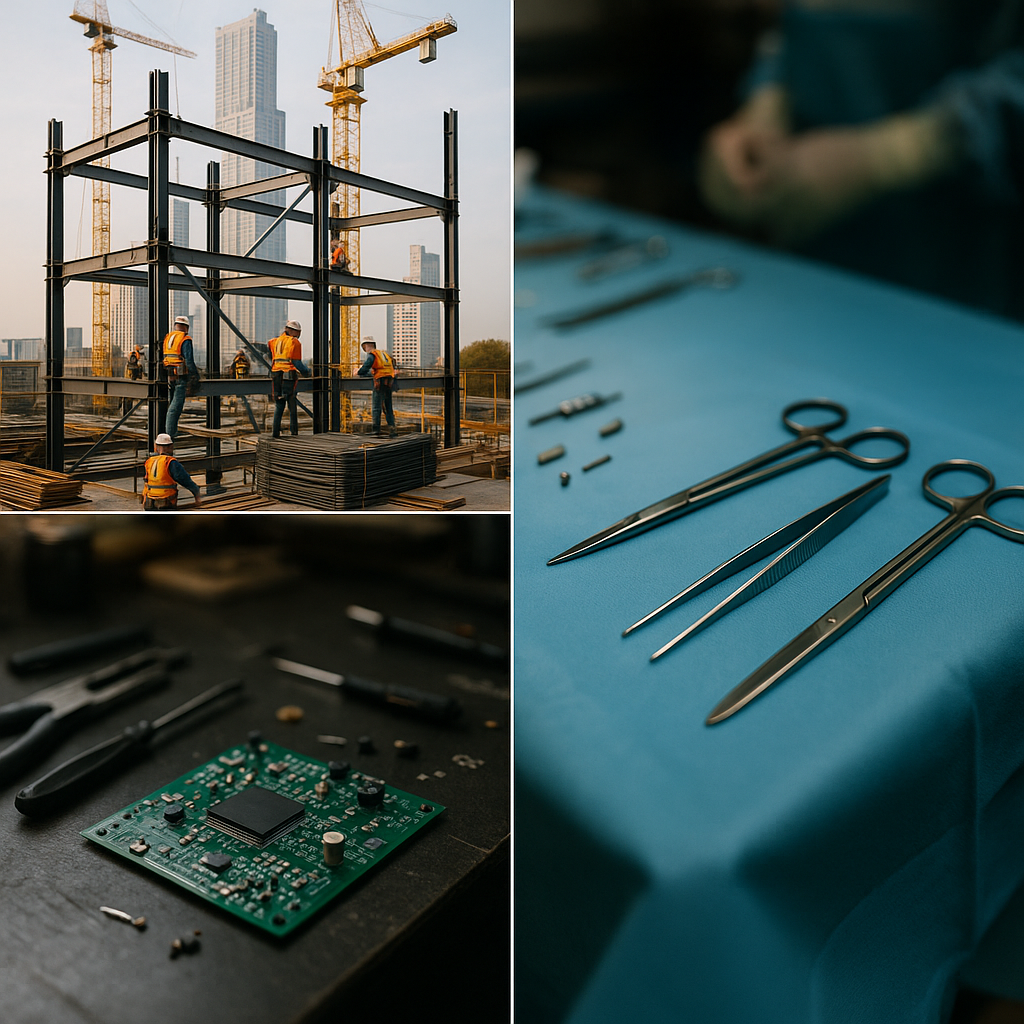

May 29, 2025Metals have shaped human civilization for thousands of years. From the earliest tools to modern skyscrapers, metals form the backbone of our technological progress. These versatile materials account for roughly 75% of all elements in the periodic table, making them abundant resources that touch almost every aspect of our daily lives.

The diversity of metals is remarkable. Common types include aluminum, brass, bronze, copper, iron, steel, titanium, lead, and precious metals like gold and silver. Each metal brings distinct characteristics. Some excel in strength, while others offer superior electrical conductivity or corrosion resistance.

Understanding these different metal types and their unique properties helps industries select the right material for specific applications. Whether building aircraft components that require lightweight durability or creating electrical systems that demand excellent conductivity, the choice of metal directly impacts performance, safety, and longevity.

What are the most common types of metals?

Metals are vital in our industrial world, with numerous varieties serving unique functions. Six metals are most commonly used across various industries: aluminum, steel, iron, copper, zinc, and lead. Each possesses distinct properties suitable for specific applications.

Aluminum is among the most widely used non-ferrous metals. Its lightweight nature combined with strength makes it ideal for aircraft manufacturing, food packaging, and window frames. Aluminum’s excellent corrosion resistance eliminates the need for protective coatings, saving time and money in maintenance.

Steel dominates the metal industry with nearly two billion tons produced annually in over 3,500 different grades. This iron-carbon alloy typically contains 99% iron and 1% carbon. The carbon addition maintains iron’s strength while reducing weight and corrosion vulnerability. Steel forms the backbone of modern infrastructure from skyscrapers to bridges and railway tracks.

Iron remains fundamental to manufacturing despite its susceptibility to rust. Pure iron boasts high melting points and a rigid structure, making it ideal for cookware, stoves, and heavy machinery. About 90% of manufactured metals are iron-based, largely due to iron comprising approximately 5% of Earth’s crust – making it both abundant and affordable.

Copper has served human civilization for over 6,000 years. This distinctive reddish-brown metal excels in electrical and thermal conductivity while resisting corrosion remarkably well. Modern applications include electrical wiring, plumbing pipes, and telecommunication components. Though more expensive than some alternatives, copper’s durability and performance justify its continued use.

Zinc contributes significantly to manufacturing and construction sectors. Its most common application involves galvanizing steel and iron to prevent rust, extending the lifespan of numerous products. Zinc also serves as a critical component in brass alloys, die-casting for automotive parts, and roofing materials due to its weather-resistant properties.

Lead, despite environmental concerns, remains important in specific applications. Its malleability, low melting point, and excellent corrosion resistance make it valuable for power cables, batteries, and radiation shielding. The construction industry still utilizes lead for roofing materials and sound dampening.

These six metals form the foundation of our modern industrial ecosystem, each bringing unique attributes that engineers and manufacturers leverage to create everything from microscopic electronic components to massive architectural structures. Their versatility ensures they’ll remain crucial materials far into the future.

What Are the Characteristics of Ferrous Metals?

Ferrous metals contain iron as their primary component, giving them distinctive properties that are invaluable across numerous industries. These metals typically have a high carbon content ranging from 2% to 5%, which significantly influences their performance characteristics.

The most notable characteristic of ferrous metals is their exceptional strength, particularly in compression. This makes them ideal for structural applications where load-bearing capacity is essential. Their crystalline structure provides stability but can make them somewhat brittle under tension.

Magnetic properties are another defining feature of ferrous metals. The iron content makes them naturally magnetic, allowing for easy identification and separation during recycling processes. This property also makes them useful in electrical applications and motors.

Density is a significant characteristic of ferrous metals. They tend to be heavier than their non-ferrous counterparts due to their iron content. While this provides excellent stability in construction applications, it makes them less suitable for projects where weight is a concern.

Ferrous metals typically have high melting points, allowing them to withstand extreme temperatures. This property makes them essential in applications exposed to heat, such as industrial machinery, automotive components, and cooking equipment.

One notable drawback of ferrous metals is their susceptibility to corrosion. When exposed to moisture and oxygen, they undergo oxidation (rusting), which can compromise structural integrity over time. This process occurs when iron combines with oxygen in the presence of water vapor to form iron oxide.

The corrosion process can be accelerated by environmental factors such as seawater, salt air, cements, plasters, and acids. To protect against this, various coating methods like bituminous treatments, waxes, paints, and specialized metallic coatings are commonly applied.

Different types of ferrous metals offer varying combinations of these properties. Cast iron provides excellent compression strength and heat resistance, making it perfect for cookware and machinery components. Wrought iron offers malleability and aesthetic appeal for decorative elements. Carbon steel delivers exceptional strength and versatility across construction applications. Alloy steel, with additions like chromium or nickel, enhances specific properties like corrosion resistance or tensile strength.

The recyclability of ferrous metals is another valuable characteristic. These metals can be melted down and reformed multiple times without losing their essential properties, contributing to sustainability efforts in manufacturing and construction industries.

What Are the Properties of Non-Ferrous Metals?

Non-ferrous metals are defined by their lack of iron content, granting them exceptional properties invaluable across many industries. Common non-ferrous metals include aluminum, copper, zinc, lead, tin, nickel, and precious metals like gold, silver, and platinum.

A major advantage of non-ferrous metals is their superior corrosion resistance. Unlike ferrous metals, they don’t rust when exposed to moisture and air, making them ideal for marine environments, outdoor structures, and chemical processing equipment.

These metals typically weigh less than their ferrous counterparts. Aluminum, for example, has a specific gravity of about 2.7, approximately one-third the weight of steel. This lightweight characteristic is valuable in transportation industries where fuel efficiency is linked to reduced weight.

Many non-ferrous metals exhibit exceptional electrical conductivity. Copper ranks second only to silver in this regard, making it the material of choice for electrical wiring and electronics. Aluminum also conducts electricity well and is used in high-voltage transmission lines.

Thermal conductivity is another valuable property of many non-ferrous metals. Copper excels in heat transfer applications, explaining its widespread use in heat exchangers and radiators. Aluminum also dissipates heat efficiently, suitable for components like computer heat sinks.

The non-magnetic nature of these metals is crucial in applications where magnetic interference must be avoided, essential for sensitive electronic equipment, navigation instruments, and medical devices like MRI machines.

Many non-ferrous metals display excellent malleability and ductility, allowing them to be easily formed into sheets, wires, and complex shapes. Copper can be drawn into fine wires or hammered into thin sheets, while gold can be beaten into leaves just a few atoms thick.

The recyclability of non-ferrous metals adds to their environmental value. Materials like aluminum can be recycled repeatedly without losing their properties. Recycling aluminum uses only about 5% of the energy required to produce new aluminum from raw ore, significantly reducing environmental impact.

Several non-ferrous metals offer excellent machinability, allowing for precise manufacturing. Brass, an alloy of copper and zinc, is particularly valued for its machinability in applications requiring tight tolerances.

Some non-ferrous metals, particularly titanium, maintain their strength at high temperatures, making them suitable for demanding applications in aerospace, where components must withstand extreme heat while maintaining structural integrity.

The aesthetic qualities of non-ferrous metals like copper, brass, bronze, gold, and silver have made them favorites for decorative applications throughout history. Their natural colors and ability to take polish make them ideal for architectural features, jewelry, and artistic works.

Certain non-ferrous metals possess remarkable biocompatibility. Titanium, for example, is non-reactive with human tissue, making it the preferred material for medical implants, prosthetics, and surgical instruments.

The diverse properties of non-ferrous metals enable their use across a vast range of industries. From lightweight aircraft components to durable electrical infrastructure, these metals play essential roles in advancing technology and improving quality of life.

For specialized applications, non-ferrous metals can be combined to form alloys with enhanced properties. Brass combines copper’s excellent conductivity with zinc’s improved strength, while bronze alloys copper with tin to create a harder, more corrosion-resistant material ideal for marine environments.

What are the precious and rare metals?

Precious metals are rare, naturally occurring metallic elements with significant economic value. Gold, silver, platinum, and titanium are noted for their scarcity, exceptional properties, and diverse industrial applications.

Gold is recognized for its distinctive yellow color and remarkable resistance to corrosion. Its malleability and conductivity make it invaluable in jewelry, electronics, radiation shielding, and thermal insulation. Major sources include South Africa, the United States, China, and Australia.

Silver has the highest electrical and thermal conductivity of all elements. This versatile metal plays crucial roles in renewable energy technology, particularly in photovoltaic cells for solar panels. Beyond its beauty in jewelry and coins, silver is used in batteries, electronics, dentistry, and as an antimicrobial agent.

Platinum is possibly the most precious metal, being nearly 15 times rarer than gold. This dense, malleable metal offers exceptional corrosion resistance and stability. Its unique properties make it essential for catalytic converters, jewelry, and dental applications. South Africa, Canada, and Russia are the primary sources of this valuable metal.

Titanium, while not traditionally classified with precious metals, is highly valued for its extraordinary strength-to-weight ratio. This makes titanium indispensable in aerospace engineering, where durability and lightweight construction are key. Its excellent biocompatibility also makes it ideal for medical implants and prosthetics.

The value of these metals extends beyond their appearance. Their unique physical and chemical properties drive demand across manufacturing, technology, and investment sectors. As natural resources, their limited availability further enhances their economic importance in global markets.

How Are Alloys Different from Pure Metals?

Alloys are specialized materials created by combining two or more elements, with at least one being a metal. Common examples include brass (copper and zinc) and bronze (copper and tin). These combinations are specifically engineered to create materials with superior properties compared to pure metals alone.

The fundamental difference between alloys and pure metals lies in their atomic structure. Pure metals consist of identical atoms arranged in a uniform pattern, allowing atoms to slide easily past each other when force is applied, much like a deck of playing cards.

Alloys, by contrast, contain different-sized atoms that disrupt this uniform pattern. When different elements are mixed, they create a more complex atomic arrangement that prevents easy movement. This disruption is key to why alloys are typically stronger than pure metals. The varied atomic sizes create obstacles that block the movement of dislocations through the material, enhancing strength and hardness.

This structural difference leads to several advantages for alloys. Most notably, alloys offer superior strength and hardness. Steel, an alloy of iron and carbon, demonstrates this perfectly—it’s significantly stronger than pure iron because the smaller carbon atoms fit between iron atoms, preventing them from sliding past each other easily.

Corrosion resistance is another major benefit of alloys. Pure metals like iron rust readily when exposed to oxygen and moisture. However, stainless steel, which contains chromium, forms a protective oxide layer that prevents further corrosion, making it invaluable for applications in harsh environments.

Many alloys also offer improved thermal properties. They can maintain their strength at higher temperatures than pure metals, making them essential for applications like jet engines where materials must perform under extreme heat. The melting points of alloys also differ from pure metals—they typically melt over a temperature range rather than at a single temperature point.

While alloys generally exhibit superior mechanical properties, they typically have lower electrical and thermal conductivity compared to pure metals. Pure copper and silver are excellent conductors because their uniform structure allows electrons to move freely. The disrupted structure of alloys impedes this movement, reducing conductivity.

In everyday life, we rely on alloys constantly. The strength of steel makes modern skyscrapers possible. The corrosion resistance of brass makes it ideal for plumbing fixtures. The lightweight strength of aluminum alloys enables fuel-efficient vehicles and aircraft. Without these engineered materials, many modern technologies and structures wouldn’t be possible.

Conclusion: The Diverse World of Metals

The extensive variety of metals, including ferrous types like cast iron and carbon steel, and non-ferrous options such as aluminum, copper, and titanium, represents a valuable material resource. Each metal type offers distinct properties suitable for specific industrial applications. This diversity enables precise material selection across construction, manufacturing, technology, and artistic endeavors.

For professional metal recycling services that maximize the value of these materials while supporting sustainability goals, contact Okon Recycling at 214-717-4083. Our expertise ensures proper handling of all metal types for optimal environmental and economic benefits.