5901 Botham Jean Blvd, Dallas, TX 75215

Scrap Metal Purity Testing: A Complete Guide to Methods & Grading

October 17, 2025Scrap metal purity testing is a systematic evaluation of recycled metal materials to determine their exact composition, quality, and economic value. This critical assessment employs various analytical methods to identify specific metal types, measure their purity, and detect contaminants that might compromise usability. In the current circular economy, such precise evaluations underpin effective metal recycling.

The recycling industry depends on accurate testing to transform seemingly random metal waste into properly categorized resources. Without proper testing, recyclers cannot ascertain the true worth of collected materials or ensure they meet industry specifications. This process bridges the gap between collection and reprocessing, ensuring materials reach their appropriate destinations.

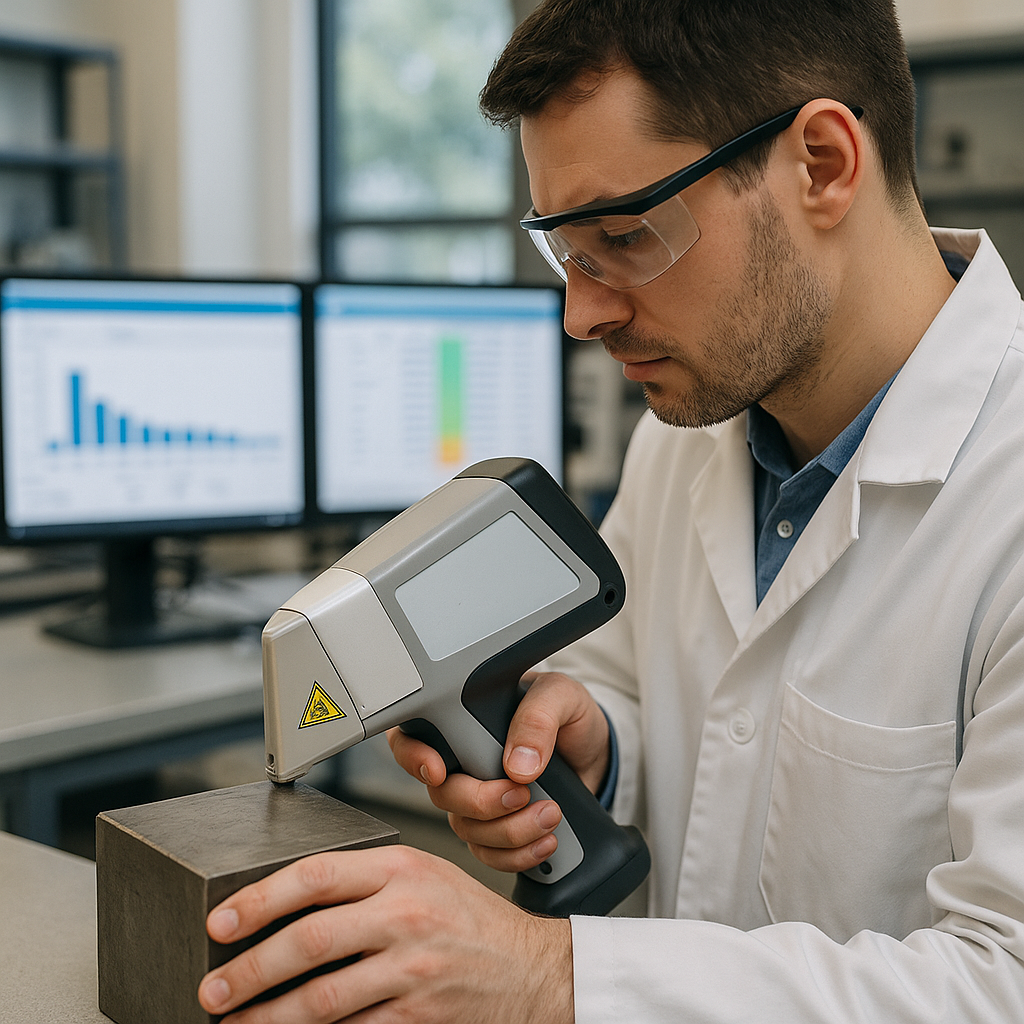

Testing methods range from simple magnetic tests that quickly separate ferrous from non-ferrous metals to sophisticated spectroscopic analysis revealing precise chemical composition. Recent advancements in portable XRF analyzers now allow recyclers to identify metal composition within seconds, dramatically improving sorting efficiency and accuracy in scrap yards across the country. The financial implications of proper testing are substantial, with price differences between properly and improperly identified metals sometimes exceeding 300%.

What Are the Basic Methods for Testing Scrap Metal Purity?

Determining scrap metal purity doesn’t always require sophisticated laboratory equipment. Several straightforward testing methods allow recyclers to quickly identify and sort different types of metals. These basic techniques form the foundation of initial metal sorting in recycling operations.

The Magnet Test

The magnet test stands as the most fundamental method for separating ferrous from non-ferrous metals. This simple yet effective technique requires only a strong permanent magnet.

- Hold a magnet near or against the metal piece.

- If the metal strongly attracts to the magnet, it contains iron and is ferrous (steel, cast iron).

- If no attraction occurs, the metal is non-ferrous (aluminum, copper, brass).

This test quickly identifies ferromagnetic materials like iron, steel, and certain stainless steel alloys. Non-ferrous metals typically command higher prices, making this initial sorting step financially significant for recyclers.

Visual Inspection

Experienced recyclers can identify different metals by appearance, focusing on color, texture, and other physical characteristics.

- Copper displays a distinctive reddish-brown color.

- Brass shows a yellowish hue.

- Aluminum appears silvery white and feels lightweight.

- Stainless steel typically has a shiny silver finish.

For metals with surface contamination, recyclers might use a metal file to scrape away the outer layer. This reveals the true color underneath any coatings or oxidation, providing valuable identification clues.

The Scratch Test

The scratch test helps determine metal hardness and malleability. Different metals leave different marks when scratched against another surface.

- Use a small nail or scratch tool on an inconspicuous area.

- Soft metals like gold and lead will dent easily.

- Harder metals like steel will show minimal marking.

- Note the color of any residue left behind.

This test works particularly well for distinguishing between metals that look similar but have different hardness properties. For instance, aluminum scratches more easily than stainless steel.

Density Measurement

Density testing provides more precise information about metal composition. This method uses the principle that different metals have unique weights per volume.

- Weigh the metal piece in grams.

- Measure water displacement when the metal is submerged.

- Calculate density by dividing weight by volume displaced.

Metals like aluminum have a density of about 2.7 g/ml, while copper is much denser at 8.9 g/ml. This significant difference makes density testing valuable for distinguishing between visually similar metals.

While advanced facilities use sophisticated equipment like X-ray fluorescence analyzers, these basic testing methods remain essential for initial sorting. They provide quick, cost-effective ways to categorize metals before more detailed analysis.

The combination of these methods allows recyclers to accurately sort materials, ensuring proper processing and maximizing the value of recycled metals. Many facilities start with the magnet test for broad categorization, followed by visual inspection and other tests for more precise identification.

| Metal | Density (g/cm³) | Magnetic Property |

|---|---|---|

| Iron (Fe) | 7.87 | Ferromagnetic |

| Cobalt (Co) | 8.9 | Ferromagnetic |

| Nickel (Ni) | 8.9 | Ferromagnetic |

| Aluminum (Al) | 2.7 | Non-magnetic |

| Titanium (Ti) | 4.5 | Non-magnetic |

| Copper (Cu) | 8.96 | Non-magnetic |

| Gold (Au) | 19.3 | Non-magnetic |

How Do Advanced Technologies Improve Scrap Metal Purity Testing?

Advanced technologies have revolutionized scrap metal recycling by enabling quick, accurate purity testing, a feat unachievable with traditional methods. This precision in identifying metal composition helps recyclers maximize material value and maintain quality standards.

X-ray fluorescence (XRF) analyzers use a focused beam of X-rays to cause atoms in the metal to emit secondary X-rays, each with unique energy signatures. These energy patterns—like fingerprints—identify the elements in the sample. XRF technology is especially effective at analyzing heavier elements, offering results within seconds without damaging the sample.

The non-destructive nature of XRF is ideal for testing valuable metals. Recyclers can identify metals such as stainless steel, nickel, cobalt, and titanium alloys without altering their composition. This is particularly valuable when sorting high-value materials that appear similar but vary widely in market value.

Optical emission spectrometry (OES) offers unmatched precision for detailed metal analysis. This technology creates an electrical spark between the instrument and the metal sample, exciting the metal atoms to emit light at wavelengths unique to each element.

OES technology can detect trace elements with exceptional accuracy, crucial for industries with strict quality requirements. Although it requires more sample preparation than other methods, OES provides comprehensive analysis of a metal’s bulk composition instead of just its surface.

Laser-Induced Breakdown Spectroscopy (LIBS) fills an important gap in metal testing capabilities. LIBS uses a high-intensity laser pulse to create a micro-plasma on the metal surface. As this plasma cools, it emits light at the wavelengths characteristic of the present elements.

LIBS is particularly valuable for its ability to detect lighter elements like carbon, lithium, beryllium, and boron—elements that XRF cannot effectively measure. This capability is crucial for sorting carbon and stainless steels, where carbon content determines material grade and performance properties.

These technologies offer practical benefits throughout the recycling process. Handheld analyzers allow for on-site testing, eliminating the need to send samples to laboratories. This reduces sorting time from days to seconds, dramatically improving operational efficiency.

They also help identify hazardous materials like lead and mercury, ensuring proper handling and disposal. By preventing contaminated materials from entering the production stream, advanced testing protects worker safety and product quality.

For recycling facilities, the economic impact is substantial. Accurate sorting of metals with similar appearances but different compositions directly affects profitability. Higher-grade alloys with fewer impurities command premium prices, while contaminated materials can be appropriately downgraded.

Each technology has specific strengths, and many recycling operations now use complementary combinations of testing methods. XRF provides rapid identification of most metals, LIBS excels at light element detection, and OES offers the highest precision for critical applications.

As global demand for metals grows, particularly for renewable energy and electric vehicle production, these advanced testing technologies play an increasingly vital role in supplying high-quality recycled materials to manufacturers.

Comparative Advantages of Metal Testing Technologies

Each testing technology offers distinct benefits depending on the specific recycling application. XRF technology provides fast, non-destructive testing ideal for sorting large volumes of scrap. Its portability makes it suitable for on-site use at collection points and processing facilities.

LIBS technology excels at detecting light elements that XRF misses, particularly carbon—the element that determines the grade of many steel alloys. This capability allows recyclers to differentiate between high-carbon and low-carbon steels that might otherwise be indistinguishable.

OES delivers lab-grade precision, detecting elements at parts-per-million levels. This makes it invaluable for final quality verification before materials are sold to manufacturers with strict composition requirements.

| Technology | Advantages | Limitations | Applications |

|---|---|---|---|

| X-ray Fluorescence (XRF) | Non-destructive; Fast results; Easy to use; Accurate for heavier elements | Limited detection of light elements; Surface sensitivity | Scrap metal sorting; Manufacturing quality control; Mining |

| Laser-Induced Breakdown Spectroscopy (LIBS) | Rapid analysis; Detects light elements; Portable | Potential for surface damage; Calibration challenges | On-site metal sorting; Alloy verification; Aerospace and automotive manufacturing |

| Optical Emission Spectrometry (OES) | Highly precise; Comprehensive elemental analysis | Sample preparation required; Not portable; Higher cost | High-grade metal recycling; Alloy production; Industrial quality control |

These advanced testing methods significantly improve upon traditional techniques like spark or acid testing, which provide limited information and often involve hazardous chemicals. Modern analyzers deliver comprehensive elemental analysis without sample destruction, making them safer, faster, and more reliable.

As scrap metal becomes an increasingly important resource for meeting global demand, these technologies will only grow in relevance. They enable the recycling industry to provide high-quality materials that meet the exacting standards of modern manufacturing, closing the loop in the circular economy of metals.

Why is Accurate Grading Important in Scrap Metal Recycling?

Accurate grading of scrap metal directly impacts its market value and recycling efficiency. In the competitive recycling industry, proper identification and classification of metals can significantly affect pricing, with higher grades commanding better prices due to reduced processing needs and increased value to manufacturers.

For instance, clean copper wire without insulation, known as bare bright copper, can fetch 15-30% more than copper with contaminants or coatings, highlighting the financial incentives for thorough sorting and proper grading throughout the recycling process.

Precise grading ensures metals are directed to suitable applications. When recyclers correctly identify and sort different metal types and qualities, the materials efficiently flow through appropriate recycling streams. This correct channeling supports the development of high-quality recycled products while preserving the integrity of manufacturing processes that rely on specific metal properties.

The environmental benefits of accurate grading are substantial. By processing metals through efficient recycling pathways, unnecessary energy consumption is minimized. For instance, recycling properly graded aluminum saves 95% of the energy required to produce it from raw bauxite ore. Similarly, recycling graded steel reduces CO2 emissions by approximately 58% compared to primary production.

Proper grading introduces essential transparency into the recycling ecosystem. By implementing standardized grading practices with clear documentation, recyclers enhance price visibility and ensure fair compensation. This structured approach reduces disputes over material quality, fostering more stable pricing models throughout the industry.

Advanced technology has revolutionized the grading process, improving both accuracy and efficiency. X-ray fluorescence analyzers can precisely determine metal composition, while Laser-Induced Breakdown Spectroscopy (LIBS) systems can identify lighter elements like carbon that affect metal properties. These innovations enhance grading accuracy and increase processing throughput, creating additional value for recyclers.

The economic impact of effective grading extends beyond immediate pricing benefits, as properly graded metals enter more efficient recycling streams, reducing processing costs across the supply chain. This efficiency helps create more stable markets and sustainable value for all participants in the metal recycling ecosystem.

For businesses generating substantial scrap metal, investing in grading protocols directly impacts the bottom line. Even small improvements in grading accuracy can yield significant financial benefits when applied consistently to large volumes of material, making accurate grading a key operational priority for successful recycling facilities.

| Metal | Grade | Price Range (USD per lb) |

|---|---|---|

| Copper | #1 Copper Tube Scrap | 3.40 – 3.55 |

| Copper | #1 Copper Wire Scrap | 3.40 – 3.55 |

| Copper | #1 Insulated Copper Wire | 2.35 – 2.55 |

| Brass | Plumbing Brass Scrap | 1.25 – 1.45 |

| Brass | Yellow Brass Scrap | 2.13 – 2.35 |

| Aluminum | Aluminum Scrap | 0.53 – 0.75 |

| Aluminum | Clean Aluminum Rims | 0.55 – 0.82 |

| Steel | Steel Scrap | 0.03 – 0.05 |

Ultimately, accurate grading forms the foundation of an efficient and profitable recycling industry. By enabling proper identification, sorting, and valuation of materials, precise grading allows recycling facilities to process metals more effectively, maximizing environmental and economic benefits while supporting a truly circular economy for these valuable resources.

Conclusion: The Future of Scrap Metal Purity Testing

As global demand for metals rises alongside increasing resource scarcity, accurate scrap metal purity testing has become more crucial. The ability to precisely identify, sort, and value scrap materials underpins the entire recycling ecosystem. Advanced technologies like XRF analyzers, LIBS systems, and sophisticated spectroscopic methods have transformed what was once a manual, error-prone process into a science-driven industry standard that supports sustainable production practices.

These technological innovations have enabled the recovery of metals with unprecedented purity levels, allowing recycled materials to meet or exceed the stringent requirements of automotive, aerospace, and construction industries. The economic and environmental benefits are substantial – recycling aluminum uses 95% less energy than producing it from raw material, while recycled steel reduces CO2 emissions by approximately 58%. Such efficiency gains demonstrate that accurate purity testing directly contributes to building a more resilient circular economy where resources are conserved and reused.

For businesses and municipalities seeking to maximize the value of their metal recycling efforts while supporting sustainability initiatives, contact Okon Recycling at 214-717-4083.