5901 Botham Jean Blvd, Dallas, TX 75215

What is Metal Shredder Residue and Why is Separation Important?

October 16, 2025When a vehicle or appliance reaches the end of its useful life, it embarks on a final journey through the recycling process. The shredding operation breaks down these complex items, allowing valuable metals to be recovered. What remains after this process is known as metal shredder residue (ASR) or auto shredder residue.

ASR is a complex mixture comprising multiple materials that weren’t captured during initial metal recovery. This heterogeneous blend typically includes plastics, rubber, glass, foam, textiles, and residual metals. It can account for up to 25% of a vehicle’s weight, with shredding facilities across the country generating hundreds of tons of this material daily.

The separation of ASR components has become increasingly important for several reasons. First, it enables the recovery of valuable metals like copper and aluminum that would otherwise be lost. Second, effective separation helps recycling operations meet strict regulatory requirements for recycling rates. Finally, proper ASR management addresses environmental concerns related to potentially hazardous materials present in the residue.

What are the Key Steps in the Metal Shredder Residue Separation Process?

The metal shredder residue separation process is a systematic approach designed to maximize material recovery. This multi-stage process ensures the efficient extraction of valuable metals and minimizes waste.

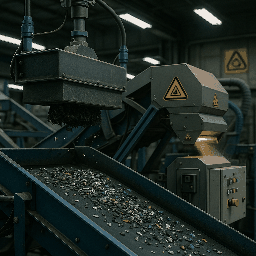

Initial Shredding

The process begins with shredding. Large metal items are fed into industrial shredders, which break them down into smaller, manageable pieces using rotating hammers or blades. This stage is crucial as proper size reduction is essential for effective downstream separation.

To optimize processing, most facilities aim for fragments between 1-10 cm in size.

Air Separation Systems

Post-shredding, the material moves to air separation units, where controlled airflow separates materials based on density and aerodynamic properties. Lighter materials like plastic, foam, and fabric are collected separately, while heavier components remain in the main processing stream.

This results in two fractions: a light fraction consisting mainly of non-metallic materials and a heavy fraction containing most of the valuable metals. Separation efficiency at this stage significantly impacts overall recovery rates.

Magnetic Separation

The next step targets ferrous metals. Powerful magnets pull iron, steel, and other magnetic materials from the mixture, recovering over 95% of ferrous metals from the waste stream.

Magnetic separation is one of the most reliable and energy-efficient stages in the process. Recovered ferrous metals are sent to melting facilities or steel mills for recycling, while remaining materials continue through additional separation stages.

Eddy Current Separation

Non-ferrous metals like aluminum, copper, and brass are separated using eddy current separators, which employ rotating magnetic fields to induce electric currents in non-ferrous metals. These currents create magnetic fields that repel the metals from other materials, facilitating collection.

This technique is particularly effective for aluminum recovery, a significant portion of non-ferrous content in metal shredder residue.

Advanced Sensor-Based Sorting

Modern facilities use sophisticated sensor technologies for final-stage separation. X-ray transmission (XRT) sensors detect materials based on atomic density, while near-infrared (NIR) systems identify different plastic types, and color sensors discern various metal grades.

Automated systems use compressed air jets to sort materials after detection, making thousands of sorting decisions per second. This technology has enabled the recovery of metals that were previously uneconomical to extract.

Final Quality Control

Despite advanced automation, human inspection remains important. Quality control stations ensure that separated materials meet purity standards required by end markets, removing any remaining contaminants or misclassified materials.

The thoroughness of this stage determines the market value of recovered materials. Higher-purity metal streams command premium prices and face fewer restrictions in global markets. Properly separated metals require less energy to recycle than mining and refining virgin materials.

What Technologies are Used for Effective Metal Shredder Residue Separation?

The recycling industry has made significant technological advances in separating valuable materials from automotive shredder residue (ASR). Modern facilities now employ sophisticated equipment capable of identifying and sorting even the smallest metal particles with remarkable precision.

Eddy current separators are crucial in metal recovery operations. These machines create a rotating magnetic field that induces electrical currents in non-ferrous metals like aluminum and copper. This interaction propels the metal particles differently from non-metallic materials, allowing efficient separation of valuable metals that might otherwise end up in landfills.

Induction sorting systems enhance metal separation by detecting all conductive objects, even those smaller than 1mm. These systems use electromagnetic fields to locate metal pieces and then precisely target them with compressed air jets, removing them from the material stream. This technology is particularly effective at recovering stainless steel and composite materials such as cables and circuit boards that traditional methods might miss.

X-ray transmission (XRT) sorters are among the most advanced technologies in the recycling industry. These machines use X-rays to analyze the atomic density of materials, creating detailed images that distinguish between different types of metals and other materials. XRT sorters can accurately identify and separate valuable heavy metals like copper, brass, and zinc from lighter materials like aluminum, significantly increasing recovery rates.

Optical sorting systems complement these technologies by focusing on non-metallic materials. Using specialized cameras and sensors, these systems identify various types of plastics, wood, and other materials based on their visual properties. Some advanced optical sorters can even identify black plastics, which traditionally challenge recycling operations due to their low reflectivity.

By combining these technologies in a single processing line, facilities create a comprehensive system capable of recovering the maximum amount of valuable materials from ASR. Modern facilities often employ multiple sorting stages, with each technology targeting specific materials to achieve the highest possible recovery rates while producing exceptionally pure material streams ready for reuse.

| Technology | Separation Efficiency | Primary Target Materials |

|---|---|---|

| Initial Shredding | Crucial for downstream processes | Reducing metal size for optimal processing |

| Air Separation Systems | Creates distinct light and heavy fractions | Plastics, foam, fabric, and heavier metal components |

| Magnetic Separation | Recover over 95% of ferrous metals | Iron, steel, other magnetic materials |

| Eddy Current Separation | Effective for aluminum recovery | Aluminum, copper, brass |

| Advanced Sensor-Based Sorting | High precision and efficiency | Various metals and non-metallics using XRT, NIR, and color sensors |

The integration of artificial intelligence and machine learning with these separation technologies represents the cutting edge of recycling innovation. These systems continuously improve sorting accuracy by learning from vast amounts of operational data, adapting to variations in input materials, and maximizing recovery rates as the composition of ASR evolves with changing automotive design and materials.

What are the Challenges and Considerations in ASR Separation?

The recycling industry faces significant challenges when separating Automotive Shredder Residue (ASR). Its complex and varied composition makes efficient separation both technically demanding and economically challenging. Understanding these obstacles is essential for developing effective solutions in the circular economy.

Material Heterogeneity

ASR consists of diverse materials differing in size, density, and physical properties, complicating separation processes significantly. Typical ASR includes plastics (up to 47%), textiles (8-12%), rubber (8-23%), and fine particles with soil and metal traces.

Compositional variability complicates the design of universal separation systems. Materials often become entangled or embedded during shredding. For instance, polyurethane foam frequently has embedded plastics, glass, and metal fines that resist mechanical separation.

Particle size distribution is another challenge, with about 90% of processed ASR measuring smaller than 30mm. These small particles require specialized equipment for effective sorting, significantly increasing processing costs.

Environmental Concerns

ASR processing carries substantial environmental implications. Untreated ASR can contain toxic substances like heavy metals, such as lead and mercury, posing contamination risks when landfilled. Studies have documented ASR with substances exceeding environmental quality standards, particularly arsenic and lead.

Processing facilities must implement robust containment measures to prevent dust emissions, leachate generation, and other potential environmental hazards. Contaminant removal often requires additional processing steps like washing with buffer solutions to reduce heavy metal concentrations to acceptable levels.

Water usage in ASR processing presents another environmental consideration. Wet separation methods, while effective for certain materials, generate wastewater that needs treatment before discharge.

Regulatory Requirements

The regulatory landscape for ASR management is becoming stricter worldwide. In Europe, the End-of-Life Vehicle (ELV) Directive mandates 95% recovery of vehicle materials, with a minimum of 85% through recycling or reuse. These targets impact how ASR must be processed.

ASR is classified as hazardous waste in many jurisdictions due to its contaminant content. This classification imposes additional handling, processing, and disposal requirements, increasing operational costs. Companies must navigate complex documentation and compliance procedures to maintain proper waste management credentials.

As circular economy principles gain regulatory backing, new requirements are emerging for extended producer responsibility. These regulations may shift some ASR management responsibilities to vehicle manufacturers, potentially altering the economics of ASR processing.

Metal Recovery Challenges

Maximizing metal recovery from ASR presents both a challenge and an opportunity. Metals typically constitute about 8% of ASR by weight, with most being fine particles that conventional magnetic and eddy current separators struggle to extract efficiently.

The economics of metal recovery from ASR heavily depend on liberation efficiency. Metals embedded in rubber or plastics require additional processing to separate, increasing energy consumption and operational costs. Achieving high recovery rates often requires multiple passes through separation equipment, reducing throughput and increasing processing costs.

Copper recovery is particularly challenging. While valuable, copper often occurs as fine wires or particles dispersed throughout the ASR. Effective copper recovery requires specialized techniques beyond conventional magnetic separation used for ferrous metals.

Market Considerations for Recovered Materials

Finding stable markets for separated ASR fractions is challenging. Recovered plastics often fail to meet manufacturers’ specifications due to contamination, degradation, or mixed polymer types. Market demand for these materials fluctuates significantly based on virgin material prices.

The energy content of non-recyclable ASR fractions offers potential value as refuse-derived fuel. However, facilities must process this material to achieve consistent combustion properties and remove contaminants that might produce harmful emissions.

Transportation costs further complicate the economics of recovered materials. The relatively low density of processed ASR fractions increases logistics costs, limiting the geographical range within which processing remains economically viable.

Conclusion: The Future of Metal Shredder Residue Separation

The future of metal shredder residue separation is at a promising crossroads. Technological innovations, such as AI-driven optical sorting systems and advanced separation technologies, are rapidly transforming the industry. These advancements will significantly enhance the recovery rates of valuable materials from what was once considered waste. As environmental regulations continue to tighten globally, the industry is being pushed toward more sustainable practices and circular economy models.

For organizations looking to optimize their metal recycling operations and stay compliant with regulatory requirements, contact Okon Recycling at 214-717-4083. Our expertise in advanced separation technologies can help maximize recovery rates and minimize environmental impact through sustainable waste management solutions.