5901 Botham Jean Blvd, Dallas, TX 75215

Key Components of Metal: Types, Properties, and Manufacturing Processes

September 25, 2025Every piece of metal, from the copper wiring in your walls to the aluminum in your smartphone, contains billions of tiny universes. At an atomic level, metals are extraordinary arrangements of particles that create some of the most versatile materials on Earth.

Metal is composed of fundamental atomic materials: electrons, neutrons, and protons. The arrangement of these particles determines the unique properties of each metal. At the core of each metal atom sits a nucleus containing positively charged protons and neutral neutrons, bound together by the strong nuclear force. Surrounding this nucleus is a cloud of negatively charged electrons.

Electrons play a crucial role, moving freely between atoms to create a ‘sea of electrons’ that gives metals their conductivity. Unlike in non-metals, where electrons are tightly bound to their parent atoms, metallic elements share their outermost electrons in what scientists call a metallic bond. This structure allows electrons to move freely throughout the material when voltage is applied, making most metals excellent conductors of both electricity and heat.

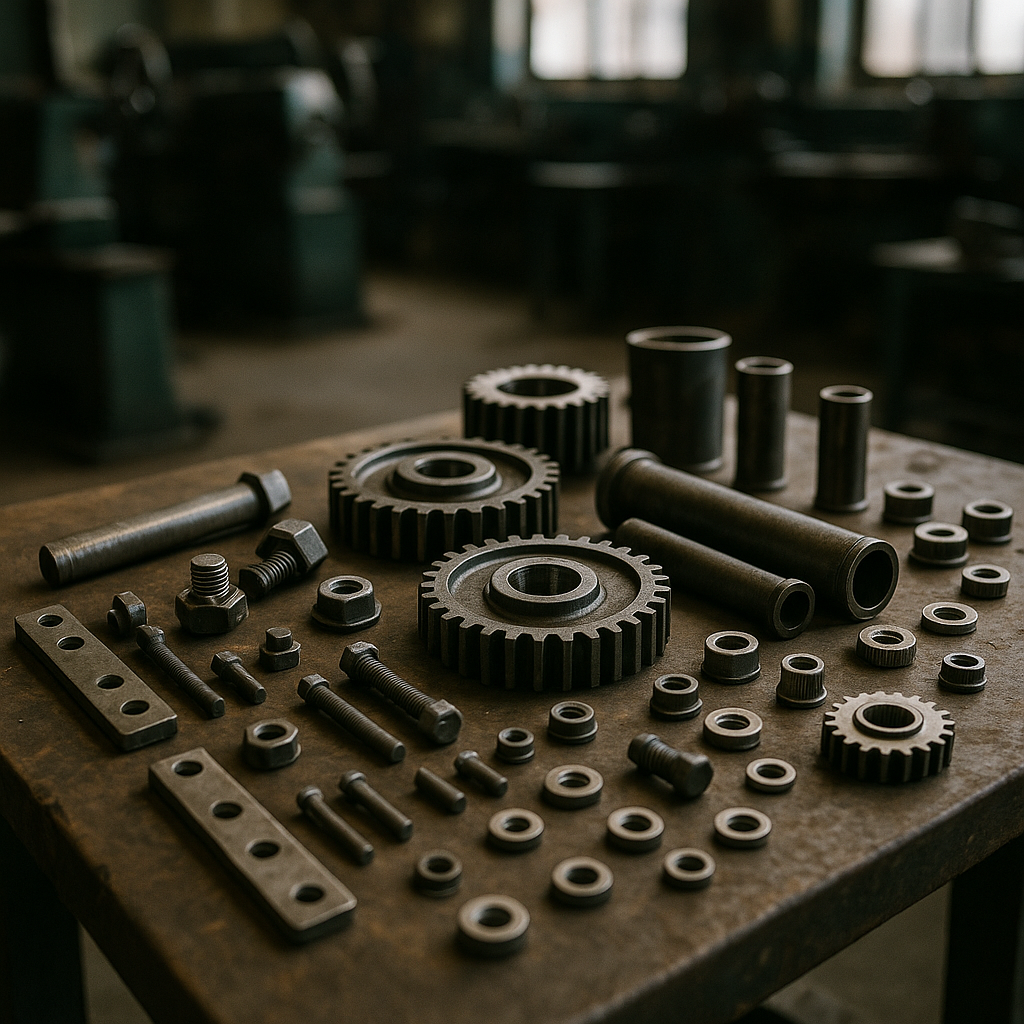

What are the Main Types of Metal Parts?

Metal parts fall into two major categories: ferrous metals, which contain iron, and non-ferrous metals, which don’t. This fundamental distinction influences their properties, applications, and recycling processes. Let’s explore the most common types of metal components used across industries today.

Ferrous Metal Components

Ferrous metals contain iron as their base element. These metals typically offer excellent strength and durability but are vulnerable to corrosion without proper treatment. Steel is the most widely used ferrous metal in manufacturing and construction.

Steel components dominate industrial applications due to their versatility and strength-to-weight ratio. Carbon steel parts are found in structural beams, automotive frames, and industrial equipment. Stainless steel components, containing chromium and nickel, provide superior corrosion resistance for applications in medical instruments, kitchen equipment, and marine environments.

Cast iron parts, containing 2-4% carbon, are valued for their excellent compression strength and vibration dampening properties. These components are common in engine blocks, pipes, and machine bases where stability is crucial.

Non-Ferrous Metal Components

Non-ferrous metals lack iron content. They often offer better corrosion resistance, higher electrical conductivity, and are typically lighter than their ferrous counterparts. These qualities make them ideal for specialized applications.

Aluminum parts are prized for their lightweight properties combined with good strength. Common applications include aircraft components, automotive parts, electronics housings, and construction elements. Their corrosion resistance and excellent thermal conductivity make aluminum components ideal for heat exchangers and radiators.

Copper elements are known for their outstanding electrical and thermal conductivity. They’re essential in electrical wiring, circuit boards, plumbing fixtures, and heat exchangers. Copper’s natural antimicrobial properties also make it valuable for medical equipment and high-touch surfaces.

Zinc components offer excellent corrosion protection and are often used as protective coatings on steel through galvanization. Pure zinc is also used in die-casting for detailed parts like carburetor components and decorative fixtures.

Metal Alloy Components

Alloys combine multiple elements to enhance performance characteristics. Brass (copper and zinc) and bronze (copper and tin) components offer unique properties that make them valuable across industries.

Brass parts provide excellent machinability, good corrosion resistance, and an attractive appearance. They’re commonly used in plumbing fixtures, musical instruments, and decorative hardware. Bronze components offer superior wear resistance and low friction, making them ideal for bearings, bushings, and marine hardware exposed to corrosive saltwater environments.

Titanium alloy components, though more specialized, are increasingly important in aerospace, medical implants, and high-performance applications where their exceptional strength-to-weight ratio and biocompatibility are crucial.

| Aluminum | Lightweight, corrosion-resistant, ductile | Aerospace, automotive, electronics, packaging |

| Copper | High conductivity, antimicrobial | Electrical wiring, plumbing, heat exchangers |

| Steel | Strong, durable, versatile | Construction, automotive, tools, appliances |

| Brass | Malleability, acoustic properties | Musical instruments, decorative items, fittings |

| Titanium | High strength-to-weight ratio, corrosion-resistant | Aerospace, medical implants, military applications |

The selection of metal parts for specific applications depends on various factors including mechanical requirements, environmental conditions, weight considerations, and cost constraints. For instance, aerospace applications typically require lightweight but strong aluminum or titanium components, while structural applications might use steel for its strength and cost-effectiveness.

In manufacturing processes, these different metals often require specialized handling. Ferrous metals typically need higher machining temperatures and are commonly processed through forging, casting, and welding. Non-ferrous metals like aluminum can be processed at lower temperatures and are suitable for extrusion and die-casting, creating complex shapes with consistent quality.

How are Metal Parts Manufactured?

Metal parts manufacturing employs various processes to transform raw materials into finished components. Each method has unique capabilities, making it suitable for specific applications, production volumes, and material needs. Explore the four primary manufacturing methods used in today’s metal fabrication industry.

CNC Machining

CNC machining is a subtractive manufacturing process using computer-controlled cutting tools to remove material from a solid block (billet). This precision-driven method creates highly accurate components with tight tolerances.

CNC machining involves two main operations: milling, which uses rotating tools to cut material along multiple axes, and turning, which spins the workpiece against stationary cutting tools. The process performs well with materials such as aluminum, stainless steel, and titanium.

Key advantages of CNC machining include:

- High precision with tolerances as tight as ±0.005 inches

- Excellent for prototyping and low-to-medium volume production

- No tooling costs for one-off parts

- Capability to work with virtually any metal

CNC machining is particularly valuable for aerospace components, medical instruments, and custom mechanical parts where precision is critical.

Die Casting

Die casting involves forcing molten metal into a reusable steel mold under high pressure. The metal solidifies quickly into the shape of the cavity, creating parts with consistent dimensions and smooth surfaces.

Two common die casting methods are hot-chamber (gooseneck) die casting, suitable for metals with lower melting points, and cold-chamber die casting, which helps limit machine corrosion. The process is similar to plastic injection molding, where the steel tool closes and molten metal flows into the mold cavity.

Die casting offers several benefits:

- High-volume production capability

- Excellent dimensional consistency between parts

- Ability to create complex shapes with fine details

- Good surface finishes requiring minimal post-processing

This process is ideal for automotive components, consumer electronics housings, and hardware products produced in large quantities.

Forging

Forging, one of the oldest metalworking techniques, shapes metal through compressive forces applied by hammering or pressing. Unlike processes that melt metal, forging preserves and aligns the metal’s grain structure, enhancing its mechanical properties.

Common forging methods include drop forging, where a hammer strikes the metal against a die, and press forging, which applies continuous pressure rather than impact. The process can be performed at high temperatures (hot forging) or near room temperature (cold forging).

Forging provides unique advantages:

- Superior strength and durability

- Enhanced resistance to impact and fatigue

- Improved directional strength through aligned grain structure

- Excellent for high-stress applications

Industries rely on forged parts for critical components like engine crankshafts, gears, and aerospace structural elements.

Metal Injection Molding (MIM)

Metal injection molding combines the versatility of plastic injection molding with the strength of metal. The process begins by mixing fine metal powder with a polymer binder to create a feedstock that can flow when heated.

This mixture is injected into a mold cavity under pressure. After cooling, the “green” parts undergo debinding to remove the polymer, followed by sintering at high temperatures to fuse the metal particles together, resulting in a dense metal part.

MIM offers significant benefits for specific applications:

- Ability to produce small, complex parts with intricate features

- High production volumes with consistent quality

- Good surface finishes and material properties

- Cost-effective for small, complex components

Metal injection molding excels in producing small precision components for industries like medical devices, electronics, and automotive applications.

| Method | Process Description | Advantages | Disadvantages |

|---|---|---|---|

| Machining | Cuts material from workpiece | High level of geometrical freedom; No costly tooling | Worse results with harder metals; Slow for mass production |

| Forging | Applies force to workpiece | Very strong parts; Compatible with desirable metals | Very high costs in all aspects; Limited geometrical freedom |

| Casting | Melts metal and forms it in a mold | Can be fast and repeatable; Range of processes | Tooling costs and lead times; Limited geometrical freedom |

| Powder Metallurgy | Forms part in mold then sinters it | Wide range of metals and alloys | Hazardous raw material |

| Additive Manufacturing | Fuses metal powder particles in successive layers | Very high level of geometrical freedom; No costly tooling | Slow for mass production; Limited part strength |

| Extrusion | Forces workpiece through shaped die opening | Fast for medium-large volumes | Limited geometrical freedom |

When selecting a manufacturing process, engineers must consider factors such as part complexity, production volume, material requirements, and cost constraints. Often, the optimal solution might involve combining methods, such as using forging for strength followed by CNC machining for precise features.

What are the Key Properties of Metal Parts?

Metal parts possess distinct physical and mechanical properties that determine their suitability for recycling and various industrial applications. Understanding these properties helps in both the effective processing of metal waste and determining the most appropriate recycling methods.

Conductivity is a vital characteristic of metals. Metals like copper and aluminum excel at conducting electricity and heat, which explains why copper wiring remains essential in our homes and buildings. When we touch a metal pot handle that’s become hot on the stove, we’re experiencing thermal conductivity.

Malleability allows metals to be shaped under compression without breaking. This property enables metals like aluminum to be pressed into thin sheets for food packaging or vehicle bodies. Consider how easily you can crush aluminum cans in your hand—that’s malleability at work.

Ductility refers to a metal’s ability to be stretched into wire without fracturing. This property allows copper to be drawn into the miles of wiring that power our cities and homes. When electricians pull copper wiring through walls, they rely on this essential property.

Metals typically exhibit luster, or shininess, when polished. This reflective quality makes metals like stainless steel and chrome popular for decorative applications in everything from kitchen appliances to automotive trim. The gleaming surface of a new bicycle frame demonstrates this clearly.

Strength varies significantly among metals, with steel offering exceptional tensile strength, making it ideal for construction frameworks and machinery. The steel beams supporting skyscrapers showcase the importance of this property in modern infrastructure.

Metal parts also display varying degrees of hardness, which determines their resistance to scratches and dents. Titanium’s exceptional hardness makes it valuable for surgical instruments and aerospace components where durability is crucial.

Corrosion resistance differs widely among metals. While iron rusts readily when exposed to moisture, stainless steel contains chromium, forming a protective oxide layer that makes it resistant to corrosion. This is why outdoor stainless steel furniture can withstand years of weather exposure.

Density affects a metal’s weight relative to its volume. Aluminum’s low density makes it preferable for applications where weight matters, like aircraft components and beverage cans. In contrast, lead’s high density makes it useful for radiation shielding and ballast applications.

How Metal Properties Influence Recycling Processes

Each metal property directly impacts how it’s handled during recycling. Metals with high melting points require more energy during reprocessing, while those with greater ductility and malleability may be easier to compact and transport. Recycling facilities must consider these properties when designing their processing systems.

The recyclability of metals is a key sustainability feature. Unlike many materials that degrade during recycling, metals can be reprocessed repeatedly without losing their essential properties. An aluminum can today might become part of an airplane tomorrow and then a building component in the future.

Metals’ distinct properties also make them relatively easy to separate from mixed waste streams. Their conductivity, magnetism, density, and other characteristics enable automated sorting technologies to achieve high recovery rates, making metal recycling particularly efficient compared to other materials.

| Metal Type | Properties | Common Applications |

|---|---|---|

| Steel | High strength, malleable, relatively low cost | Structural beams, automotive frames, surgical instruments |

| Copper | High electrical and thermal conductivity, corrosion-resistant | Electrical wiring, plumbing fixtures, circuit boards |

| Aluminum | Lightweight, corrosion-resistant, good thermal conductivity | Aircraft components, automotive parts, heat exchangers |

| Brass | Good machinability, corrosion resistance | Plumbing fixtures, musical instruments, decorative hardware |

| Bronze | Superior wear resistance, low friction | Bearings, bushings, marine hardware |

| Titanium | High strength-to-weight ratio, biocompatible | Aerospace, medical implants, high-performance applications |

By understanding these fundamental properties, recyclers can maximize the value recovered from metal waste streams while ensuring that these versatile materials remain in productive use rather than ending up in landfills. The combination of recyclability and diverse physical properties makes metals particularly valuable in our transition to a more circular economy.

Conclusion: The Importance of Understanding Metal Parts

Understanding metal parts and their composition is essential for driving innovation across various industries. From precision components in aerospace to structural elements in construction, metal parts form the backbone of our modern world. Knowledge of different metal types, manufacturing processes, and material properties enables engineers to create custom solutions that meet specific performance requirements while optimizing for cost, durability, and efficiency.

This understanding extends beyond manufacturing. It plays a crucial role in advancing sustainable practices through the circular economy. When engineers and designers grasp metal composition and properties, they can make more informed choices about material selection, design for disassembly, and recyclability. These decisions help reduce waste, conserve resources, and minimize environmental impact.

For organizations committed to sustainability, comprehensive knowledge of metal parts is a powerful tool for implementing effective recycling programs and contributing to a more circular economy. For your metal recycling needs, contact Okon Recycling at 214-717-4083.