5901 Botham Jean Blvd, Dallas, TX 75215

Electrowinning Process for Metal Recovery: Principles, Efficiency, and Industrial Applications

October 15, 2025Electrowinning, also known as electroextraction, is an electrolytic process used to recover metals from solutions containing metal ions. This process transforms dissolved metals into solid form using a controlled electrical current. When this current is applied to a solution, it causes metal ions to deposit onto a cathode, creating a pure metal product that can be harvested and further processed.

This effective recovery technique has become a cornerstone of modern metal processing. Mining companies, recycling facilities, and metal refineries rely on electrowinning to extract valuable metals like copper, gold, silver, zinc, and nickel from leach solutions. The technology is particularly valuable in processing lower-grade ores that would otherwise be uneconomical to mine.

Despite its industrial importance, electrowinning is surprisingly straightforward at its core. An electrical current passes from an inert anode through a metal-containing solution to a cathode. The dissolved metal ions in the solution are attracted to the negatively charged cathode, where they gain electrons and transform into solid metal. This electrochemical reaction allows for high-purity metal recovery, often achieving recovery rates of up to 99% for certain metals.

How Does the Electrowinning Process Work?

Electrowinning is an electrochemical process that recovers metals from solution through the application of electrical current. It operates on a straightforward principle yet achieves remarkable efficiency in metal recovery operations.

At its core, electrowinning involves passing an electrical current from an inert anode through a metal-rich solution to a cathode. The dissolved metal ions in the solution are attracted to the cathode where they receive electrons, become reduced to their metallic form, and deposit as a solid layer. This results in a purified metal product that can be harvested for commercial use.

The Basic Setup

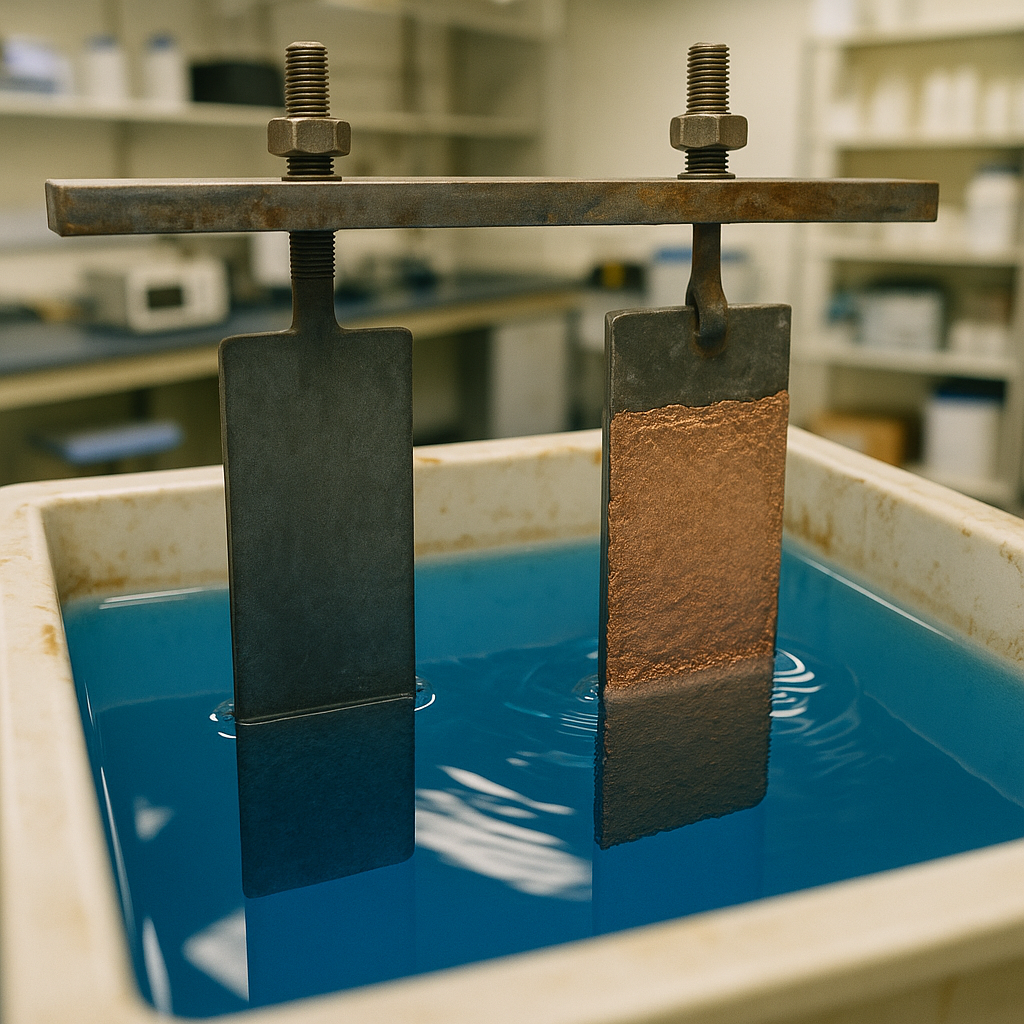

A typical electrowinning system consists of several key components working together. The heart of the system is the electrolytic cell, which contains the metal-rich solution. Within this cell are the electrodes – the anode and cathode – positioned at a specific distance from each other.

The anode is typically made from an inert material such as lead or titanium coated with precious metal oxides to prevent its degradation during the process. The cathode is usually constructed from stainless steel, aluminum, or titanium, providing the surface where the metal deposition occurs.

A direct current power source, known as a rectifier, supplies the necessary electrical current to drive the reaction. This current flows from the anode through the solution to the cathode, creating the electrical potential needed for metal reduction and deposition.

The Step-by-Step Process

The electrowinning process follows a sequence of electrochemical reactions:

- The metal-rich solution enters the electrolytic cell, typically from a prior leaching or solvent extraction process.

- When the electrical current is applied, oxidation occurs at the anode. In aqueous solutions, this usually involves the evolution of oxygen gas.

- At the same time, the dissolved metal ions in the solution migrate toward the negatively charged cathode.

- At the cathode, reduction occurs as the metal ions receive electrons and transform into their solid metallic state.

- The reduced metal deposits onto the cathode surface, building up a layer of pure metal.

- Solution circulation systems maintain proper flow within the cell, ensuring consistent metal deposition and preventing overheating.

Key Factors Affecting Performance

Several factors influence the efficiency of the electrowinning process:

The concentration of metal ions in the solution directly affects the deposition rate. Higher concentrations generally yield faster recovery rates up to certain limits. The composition of the electrolyte solution is carefully controlled to optimize conductivity and metal solubility.

Current density – the amount of current applied per unit area of cathode – is a critical parameter. Too little current results in slow deposition rates, while too much can cause poor deposit quality or excessive heat generation.

Temperature must be monitored as it affects solution conductivity and reaction kinetics. Many operations include cooling systems to maintain optimal temperature ranges.

Recovery Rates and Efficiency

The electrowinning process is highly efficient. For certain metals like copper, zinc, and nickel, recovery rates can reach up to 99% under optimal conditions. This high efficiency makes electrowinning an economically viable method for recovering valuable metals from relatively dilute solutions.

Modern electrowinning operations often incorporate automation and monitoring systems to maintain precise control over process parameters. These systems can adjust current density, solution flow rates, and other variables to maximize recovery while minimizing energy consumption.

The purity of the recovered metal is another notable advantage. Electrowinning can produce metal deposits of exceptional quality, often exceeding 99.9% purity when properly controlled.

| Component | Function |

| Electrolytic Cell | Contains the metal-rich solution and provides the environment for metal ion deposition onto the cathode |

| Anode | Made of an inert material, facilitates oxidation and current flow |

| Cathode | The site where reduced metal ions deposit as solid metal |

| Rectifier | Supplies direct current to drive the electrochemical reactions |

| Pump | Circulates the electrolyte solution to maintain flow and temperature |

The electrowinning process has become essential in modern metallurgical operations, providing an efficient method to recover and purify metals with minimal environmental impact compared to traditional smelting techniques. Its ability to selectively recover specific metals from solution makes it particularly valuable in recycling operations and for processing complex ores.

What Are the Key Parameters for Efficient Electrowinning?

Electrowinning efficiency relies significantly on maintaining optimal operating conditions. The recovery of metals like copper, zinc, and cobalt requires precise control of several critical parameters to maximize yield while minimizing energy consumption.

Current Density

Current density is a major factor in electrowinning operations, directly affecting the rate and quality of metal deposition. For most commercial applications:

- Copper and zinc electrowinning typically operates at 200-375 A/m².

- Nickel electrowinning from sulfate solutions generally uses 200-240 A/m².

- Cobalt electrowinning shows optimal efficiency at around 400 A/m² at appropriate pH levels.

Current density must be carefully balanced. Too low, and production rates drop. Too high, and deposit quality suffers with rough, nodular formations, potentially causing short circuits between anodes and cathodes. Higher current densities also increase power consumption, raising the specific energy requirement from approximately 2 kWh/kg to over 6 kWh/kg of metal produced.

Electrolyte Temperature

Temperature significantly impacts conductivity, reaction kinetics, and deposit characteristics. The optimal range typically falls between 40-60°C, offering specific benefits such as:

- Enhanced electrolyte conductivity, reducing cell voltage and power consumption.

- Increased ion mobility, improving deposition efficiency.

- Improved deposit morphology and reduced internal stress in the metal.

For cobalt electrowinning specifically, temperatures of 60-65°C have shown favorable results. However, excessive temperatures can accelerate evaporation, increase heating costs, and cause unwanted side reactions or degradation of additives used to control deposit properties.

pH Control

Electrolyte pH profoundly influences electrodeposition mechanisms and efficiency. Most electrowinning operations maintain specific pH ranges:

- Copper and zinc: pH 2.2-2.3 is typical.

- Nickel from sulfate solutions: pH 2.0-4.0, with pH 4.0 often yielding higher current efficiency.

- Cobalt: pH 4.0-5.0 has demonstrated current efficiencies exceeding 94%.

pH control is critical as it affects hydrogen evolution (a competing reaction that wastes electrical current), metal solubility, and deposit characteristics. Lower pH can increase hydrogen evolution and reduce current efficiency, while higher pH may cause precipitation of metal hydroxides in the electrolyte.

Electrolyte Composition

Beyond the target metal concentration, electrolyte additives play crucial roles:

- Metal ion concentration must remain sufficiently high to prevent depletion at the cathode surface.

- Organic additives like gelatin or glue help control deposit morphology.

- Supporting electrolytes (often sulfates) enhance conductivity.

- Impurity levels must be monitored as they can co-deposit and reduce product quality.

For copper electrowinning, maintaining copper concentration between 30-80 g/L is typical, while cobalt processes often operate at 60-65 g/L of cobalt.

Advanced Control Systems

Modern electrowinning operations rely on sophisticated control systems to maintain optimal conditions:

- High-efficiency rectifiers with precise current control.

- Real-time monitoring of cell voltages to detect shorts and process deviations.

- Automated temperature regulation systems.

- Continuous pH measurement and adjustment.

- Electrolyte circulation to maintain uniform composition.

These systems help maximize current efficiency, directly impacting energy consumption and operating costs. Current efficiency in well-managed operations can exceed 90% for many metals, with modern copper electrowinning plants achieving 95-97% efficiency under optimal conditions.

What Are the Advantages of Electrowinning for Metal Recovery?

Superior Recovery Rates

Electrowinning is distinguished by its excellent metal recovery efficiency, achieving rates of up to 99%, which significantly surpass conventional extraction methods. This high efficiency ensures nearly all metal content from the solution is captured and utilized.

The process uses a direct electrical current to specifically target metal ions for reduction and deposition, which minimizes the losses often seen in traditional recovery systems. For operations processing precious metals like gold and silver, this high recovery rate enhances profitability.

Industries dealing with valuable metals cannot afford material losses. Electrowinning consistently delivers, even with complex solutions containing varying metal concentrations.

Exceptional Metal Purity

One of the primary advantages of electrowinning is the high purity of the recovered metals. The electrochemical deposition process naturally produces high-grade metal products without the contamination issues found in pyrometallurgical methods.

This is particularly beneficial for industries that demand ultra-pure metals. Electronics manufacturers, precious metal refiners, and specialized industrial applications benefit from electrowinning’s capability to meet strict purity standards.

The process’s selectivity allows for effective separation of target metals from impurities. In copper recovery operations, electrowinning regularly produces cathode copper with purities surpassing industry standards.

Cost-Effectiveness and Operational Savings

Compared to traditional smelting processes, electrowinning offers significant economic benefits. Operational costs are generally lower due to reduced energy requirements. Unlike pyrometallurgical methods that need high temperatures, electrowinning operates at near-ambient conditions.

The process requires fewer chemicals than many other recovery methods, translating into lower material costs and simplified logistics. Maintenance demands are also less intensive than those of complex smelting operations.

Long-term operational stability enhances cost-effectiveness further. Modern electrowinning systems can operate continuously with minimal oversight, reducing labor expenses while maintaining steady production.

Environmental Advantages

In the current sustainability-focused industrial landscape, electrowinning presents noteworthy environmental benefits. Unlike traditional smelting, electrowinning generates minimal air pollutants, eliminating concerns about sulfur dioxide and particulate emissions due to the absence of combustion.

Another significant environmental advantage is water conservation. Electrowinning systems generally use less water than conventional methods, and many modern systems incorporate closed-loop water recycling to further conserve resources.

The process also produces less waste. Without the slag and byproducts common in pyrometallurgical processes, electrowinning reduces its environmental impact. A smaller waste stream helps meet increasingly strict environmental regulations.

Versatility Across Metal Types

Electrowinning showcases notable versatility in metal recovery applications. It effectively recovers precious metals like gold, silver, and platinum group metals with outstanding efficiency, making it invaluable in mining, electronics recycling, and jewelry manufacturing.

It is also effective for base metals. Copper, zinc, nickel, and cobalt can all be extracted through well-configured electrowinning systems, enabling diverse metal-bearing waste streams to be processed.

The process is adaptable to various feed solutions, from mining leachates and industrial effluents to recycling mixtures. Electrowinning can be adjusted for specific recovery needs, positioning it as a key technology in the circular economy approach to metal resources.

What Are the Challenges and Considerations in Electrowinning?

Electrowinning offers remarkable metal recovery efficiency, but implementing this process comes with several technical and operational challenges. These challenges require careful consideration to ensure optimal system performance and environmental compliance.

Wastewater Treatment Demands

One significant challenge in electrowinning is managing the process wastewater. The electrochemical reactions generate effluent containing residual metal ions, acids, and other contaminants that require proper treatment before discharge. These wastewaters can contain complex mixtures of metals and chemicals that vary based on the source material being processed.

Modern facilities typically implement closed-loop water systems to minimize environmental impact. These systems include treatment stages specifically designed to precipitate metals, neutralize pH, and remove suspended solids before water recycling or discharge.

Efficiency Variations Based on Solution Parameters

The efficiency of electrowinning operations can fluctuate significantly based on several factors. Solution composition plays a critical role, as the presence of certain ions can either enhance or interfere with target metal deposition. For example, research indicates that iron in copper-containing wastewater can actually reduce energy consumption during the electrowinning process by decreasing cell voltage.

Other factors affecting efficiency include:

- Metal concentration in solution (depletion zones form as concentration decreases)

- Solution temperature and viscosity

- pH levels and solution conductivity

- Presence of organic compounds or surfactants that may inhibit deposition

Industry practitioners often conduct extensive testing to determine optimal solution parameters for specific metal recovery operations, balancing recovery rates with energy consumption.

Cathode Maintenance Requirements

Proper cathode installation and maintenance are essential for successful electrowinning. When cathodes are improperly installed or maintained, issues like uneven metal deposition and metal redissolution can occur. These problems not only reduce recovery efficiency but may also contaminate the recovered metal.

Regular maintenance procedures include:

- Inspection for physical damage or warping

- Cleaning to remove buildup that could affect current distribution

- Ensuring proper electrical connections to maintain consistent current flow

- Monitoring deposition patterns to identify potential issues early

Some operations have adopted advanced cathode designs like spiral-wound electrodes or 3D copper foam substrates to improve performance and simplify maintenance requirements.

Energy Consumption Considerations

Energy consumption is one of the most significant operational considerations in electrowinning. The process is inherently energy-intensive, with electricity driving the electrochemical reactions that deposit metals onto cathodes. Energy costs can represent a substantial portion of operational expenses, especially for large-scale operations.

Industry innovations to address energy concerns include:

- Optimizing cell design to reduce electrical resistance

- Implementing precise current control systems

- Using high-conductivity electrolytes when possible

- Exploring alternative electrode materials with improved performance

Modern electrowinning facilities often incorporate energy management systems to monitor and optimize electricity usage, balancing recovery rates with energy efficiency.

Operating Parameter Control

Maintaining precise control of operating parameters presents another significant challenge. Current density, voltage, temperature, and solution flow rate all require careful monitoring and adjustment. Deviations from optimal parameters can lead to poor quality deposits, reduced efficiency, or increased energy consumption.

Advanced facilities now employ automated control systems with real-time monitoring capabilities. These systems can make continuous adjustments to maintain optimal conditions despite changing input characteristics. Monitoring equipment typically tracks key parameters including solution chemistry, temperature, and electrical characteristics across the electrowinning cells.

| Factor | Description |

| Current Efficiency | The ratio of actual metal plated from an electrolyte to the theoretical mass predicted by Faraday’s law. |

| Cell Voltage | Governed by conductivity of the solution, electrode gap, solution temperature, and current density. |

| Specific Energy Consumption | Depending on solution composition and employed parameters, specific energy consumption can vary, such as 1.5–2.5 kWh/kg Cu with iron present, increasing to 3.5 kWh/kg Cu without iron. |

| Metals Recovered | Copper, gold, zinc, nickel, cobalt. |

| Power Source | Requires efficient DC power, rectifier control for consistent deposition and reduced energy waste. |

Despite these challenges, electrowinning remains one of the most effective methods for metal recovery from solution. By implementing proper controls, maintenance procedures, and wastewater management systems, facilities can overcome these challenges while benefiting from the process’s high selectivity and ability to produce high-purity recovered metals.

Conclusion: The Future of Electrowinning in Metal Recovery

Electrowinning has firmly established itself as an indispensable process in modern metallurgy. It efficiently recovers metals and produces high-purity products with a reduced environmental impact compared to traditional pyrometallurgical methods. Recent advancements in electrode materials, cell configurations, and intelligent process control systems have enhanced both the efficiency and sustainability of electrowinning operations, addressing previous limitations related to energy consumption and operational costs.

Looking ahead, the integration of electrowinning with complementary technologies holds great promise. Bioelectrochemical systems, renewable energy sources, and advanced monitoring capabilities are expected to transform metal recovery processes. These innovations will optimize resource use and significantly reduce the environmental footprint of metallurgical operations. As global demand for metals continues to increase alongside growing environmental concerns, sustainable recovery methods will become vital for meeting industry needs while ensuring environmental stewardship.

For metal extraction and recycling operations aiming to remain competitive and environmentally responsible, contact Okon Recycling at 214-717-4083.