5901 Botham Jean Blvd, Dallas, TX 75215

How Does Electrodialysis for Metal Recovery Work? A Process Guide

November 6, 2025Industrial operations lose billions of dollars worth of valuable metals each year through wastewater streams and acidic effluents. These precious resources often end up contaminating the environment instead of being recovered for reuse. The challenge lies in efficiently separating and concentrating these metals from complex solution matrices.

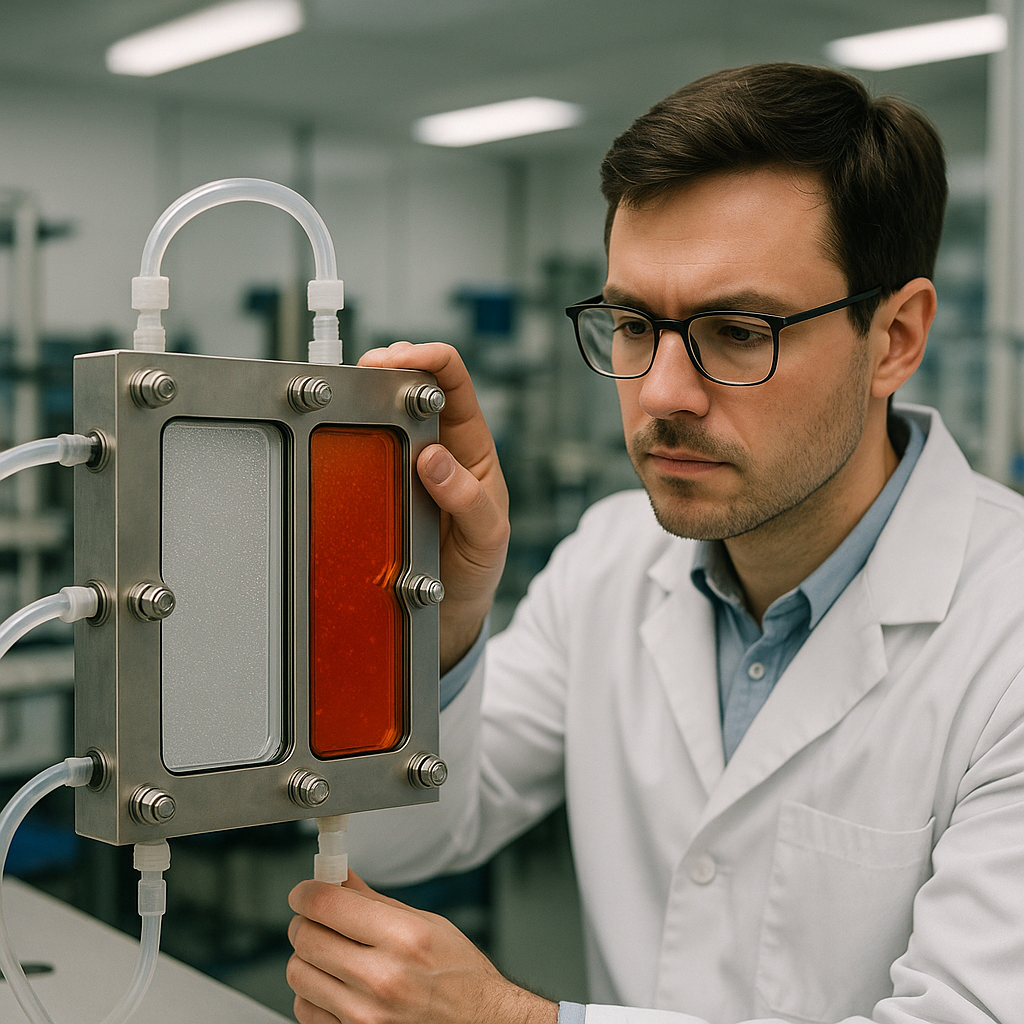

Electrodialysis (ED) is an emerging electrochemical method used to effectively remove and recover metals from various solutions. This technology utilizes ion-exchange membranes and an electric field to selectively separate charged metal ions from liquid streams. As a key technology, electrodialysis for metal recovery is crucial for isolating valuable resources from the complex mixtures found in industrial processes.

Unlike traditional precipitation methods that require chemical additives, electrodialysis offers continuous operation capacity and scalability for metal removal applications. The process enables direct reuse of concentrated metal streams, supporting circular economy principles by transforming waste into valuable resources. Recent research highlights how this selective recovery technology addresses limitations of current wastewater treatment approaches while advancing sustainable metal resource management.

Why is Selective Electrodialysis Key for Recovery?

Selective electrodialysis acts like a specialized magnet, extracting only the desired metals from complex solutions. This precision separates valuable materials from waste streams without affecting other components, specifically targeting ions while excluding unwanted substances.

Traditional metal recovery methods often face challenges with complex matrices containing multiple metals and compounds. Selective electrodialysis addresses these challenges using ion exchange membranes that recognize and transport only designated metals, ensuring high purity recovery at a molecular level.

This selectivity is crucial when processing acidic effluents from industrial operations, which typically contain diverse metal species in challenging concentrations. Selective ED technology can concentrate, separate, and selectively recover metals from acidic effluents, maintaining operational efficiency.

Focusing on specific metals within matrices boosts recovery efficiency markedly. This process removes the necessity for chemical precipitation and reduces waste, maximizing the value of recovered materials while cutting processing costs.

Selective electrodialysis provides continuous operational capacity, surpassing traditional batch processes. The technology scales effectively from pilot programs to full industrial use. Its straightforward operation lowers training requirements and simplifies processes for waste management facilities.

Direct reuse of concentrated metal streams is a significant advantage over conventional recovery methods, eliminating the need for chemical additives and reducing secondary waste. The concentrated outputs integrate seamlessly into existing recycling and material recovery workflows.

How Does an Electrodialysis System Function?

The Basic Electrochemical Process

An electrodialysis system separates ions using selective membrane technology driven by electrical current. The process generates an electric field between two electrodes, causing charged particles to move in specific directions. This electrochemical separation helps facilities target specific contaminants in wastewater streams while recovering valuable materials.

The system applies voltage between an anode and cathode positioned at opposite ends of a treatment chamber. When electricity flows through the contaminated water, positively charged ions migrate toward the negatively charged cathode, while negatively charged ions move toward the positively charged anode. This controlled ion migration is key to selective metal recovery from industrial wastewater.

Membrane Configuration and Ion Selection

The core of any electrodialysis setup is its alternating membrane arrangement. A typical system contains 200 to 400 alternating cation exchange membranes and anion exchange membranes positioned between the electrodes. These ion-selective barriers create individual compartments that channel specific types of charged particles.

Cation exchange membranes allow positively charged ions like sodium, potassium, and heavy metals to pass through while blocking negatively charged particles. In contrast, anion exchange membranes permit negatively charged ions such as chloride and sulfate to migrate while stopping positive ions. This selective permeability enables precise separation of different contaminant types from the same wastewater stream.

The membrane materials typically consist of copolymers of styrene and divinylbenzene that ensure durability and consistent ion selectivity. Advanced membrane technologies continue to enhance separation efficiency and extend operational lifespans in demanding industrial applications.

Three-Compartment System Operation

A three-compartment electrodialysis configuration creates distinct zones for feed water, concentrate collection, and dilute product recovery. The feed wastewater enters the central compartment, where ion separation starts immediately upon electrical activation. This design optimizes treatment efficiency while providing clear separation between contaminated and cleaned water streams.

As ions migrate through the selective membranes, they concentrate in alternating compartments throughout the stack. The setup creates two separate output streams: a concentrated solution containing removed contaminants and a dilute stream with significantly reduced ion content. This dual-output system enables operators to recover both clean water and valuable materials from the same treatment process.

The concentrate stream often contains recoverable metals and salts that can be further processed or sold as secondary products. The dilute stream typically meets discharge standards or can undergo additional treatment for reuse applications. This separation capability makes electrodialysis particularly valuable for facilities pursuing both compliance and resource recovery from their wastewater operations.

Conclusion: The Role of Electrodialysis in Sustainable Metal Recovery

Electrodialysis is an emerging method for metal removal and recovery from industrial waste streams. Its selective separation capabilities make it valuable for extracting metals from complex industrial mixtures. The technology’s continuous operation, scalability, and straightforward implementation address many limitations of traditional metal recovery methods. By facilitating direct reuse of concentrated metal streams without chemical precipitation, electrodialysis supports efficient resource management and circular economy principles.

As industries increasingly prioritize sustainable technology solutions, electrodialysis offers a forward-thinking approach to metal recovery that aligns with environmental goals. Its potential for treating acidic effluents while recovering valuable resources positions this technology as a cornerstone of future waste management strategies. For organizations seeking comprehensive recycling solutions that incorporate advanced metal recovery technologies, contact Okon Recycling at 214-717-4083.