5901 Botham Jean Blvd, Dallas, TX 75215

What Is the Highest Paying Scrap for Recycling?

February 5, 2026Scrap metal values vary significantly across different materials. Some metals consistently offer higher returns than others. Understanding this hierarchy of scrap metal can greatly influence your recycling profits. In early 2026, as global demand for raw materials intensifies due to the green energy transition, the gap between high-value non-ferrous metals and standard steel has widened, making strategic sorting more important than ever.

Copper is the leading performer in scrap metal recycling. Current market rates show copper selling for premium prices per pound at most recycling centers. This makes copper worth significantly more than standard steel, establishing it as the most valuable non-ferrous metal in the recycling industry. Driven by the expansion of electric vehicle (EV) infrastructure and artificial intelligence data centers, copper has become a critical resource for the modern economy.

The value hierarchy includes not only copper but also brass, aluminum, stainless steel, and various specialty alloys. While scrap metal prices fluctuate with market conditions like the London Metal Exchange (LME), the relative positioning of these materials remains stable. Knowing which metals provide the highest returns helps maximize the profitability of your recycling efforts.

Why Is Copper the King of Scrap Metals?

Copper commands the highest prices in scrap yards across the country for reasons that extend beyond its distinctive reddish appearance. This non-ferrous metal consistently outperforms other recyclable materials, with clean copper fetching up to 40 times more value than steel. The foundation of copper’s dominance lies in its exceptional electrical conductivity. Only silver surpasses copper in conducting electricity, making it irreplaceable in power transmission, electronics manufacturing, and data infrastructure.

The “Electrification” demand surge

In 2026, the demand for copper is being driven by the rapid electrification of the global economy. Every commercial wind turbine requires approximately 3.6 tons of copper, while electric vehicles contain four times more copper than conventional internal combustion cars. Furthermore, the explosion of AI data centers in North Texas has created a massive need for heavy-duty copper bus bars and cabling. This industrial necessity creates consistent, growing demand that supports premium pricing for recycled material.

Grades of copper: Bare Bright vs. #1 vs. #2

To maximize value, recyclers must understand the grading system. Bare bright copper wire is the “gold standard”—this is 99.9 percent pure wire that is free of insulation, tarnish, or paint. It commands the highest price. Below that is #1 Copper, which includes clean tubing and bus bars free of solder. Finally, #2 Copper includes tubing with paint or solder and oxidized wire. Properly sorting these grades ensures you are paid for the highest quality material you possess.

Recycling efficiency sets copper apart from virtually every other material in the waste stream. Unlike plastics or paper that degrade with each recycling cycle, copper maintains its full properties indefinitely. This infinite recyclability means that approximately 75 percent of all copper ever mined remains in active use today. Processing recycled copper requires 85 percent less energy than extracting new copper from ore, a significant savings that mills pass on to recyclers in the form of higher buy-back rates.

Advanced Metal Identification Technology in 2026

Gone are the days when a simple magnet and a spark test were the only tools for identifying scrap. The modern recycling industry relies on advanced scientific instruments to ensure that you are paid for the exact chemical composition of your metal.

XRF analyzers and chemical precision

Handheld X-ray Fluorescence (XRF) analyzers have revolutionized the scrap yard. These devices look like radar guns but function as portable laboratories. By shooting an X-ray beam into the metal, the device reads the fluorescent energy emitted by the electrons, providing a readout of the elemental composition in seconds. For a customer, this means there is no guesswork involved in distinguishing between a piece of 304 stainless steel (containing 8 percent nickel) and 316 stainless steel (containing 10 to 12 percent nickel and molybdenum). Since nickel is a high-value commodity, identifying 316 stainless can significantly increase the payout per pound.

LIBS technology for aluminum grading

Another leap forward is Laser-Induced Breakdown Spectroscopy (LIBS). While XRF is excellent for heavy metals, LIBS is specialized for lighter elements like aluminum, magnesium, and lithium. In the automotive recycling sector, distinguishing between different aluminum alloys—such as the 6000 series used in structural components versus the 7000 series used in aerospace—is vital. LIBS technology allows recyclers to grade aluminum with laboratory precision, ensuring that high-performance alloys are not downgraded to “mixed sheet” pricing.

Navigating the 2026 Supply Chain and Legal Landscape

The scrap metal industry does not operate in a vacuum. It is tied directly to global geopolitics, supply chain resilience, and increasingly strict state regulations regarding critical infrastructure.

Reshoring and domestic demand

The push to “reshore” manufacturing back to the United States has created a hungry domestic market for scrap. Texas steel mills, operating highly efficient Electric Arc Furnaces (EAFs), rely almost exclusively on scrap steel rather than iron ore. This means that the steel you recycle in Dallas or Fort Worth is likely to stay in Texas, being melted down to create rebar for local highways or beams for new skyscrapers. This local loop reduces transportation costs and carbon emissions, stabilizing prices even when international markets are volatile.

Texas legislation on critical infrastructure (HB 3552 / SB 1646)

It is crucial for recyclers to be aware of the 2025–2026 legislative updates in Texas. New laws, such as SB 1646, have increased penalties for the theft of copper, aluminum, and brass, specifically from critical infrastructure like telecommunications towers and power grids. Legitimate recycling centers now enforce stricter identification and record-keeping protocols. Sellers should be prepared to provide valid government ID and, in some cases, proof of ownership for commercial-grade materials like burnt wire or heavy gauge cable. These laws protect the integrity of the industry and ensure that legitimate recyclers are not competing with black-market material.

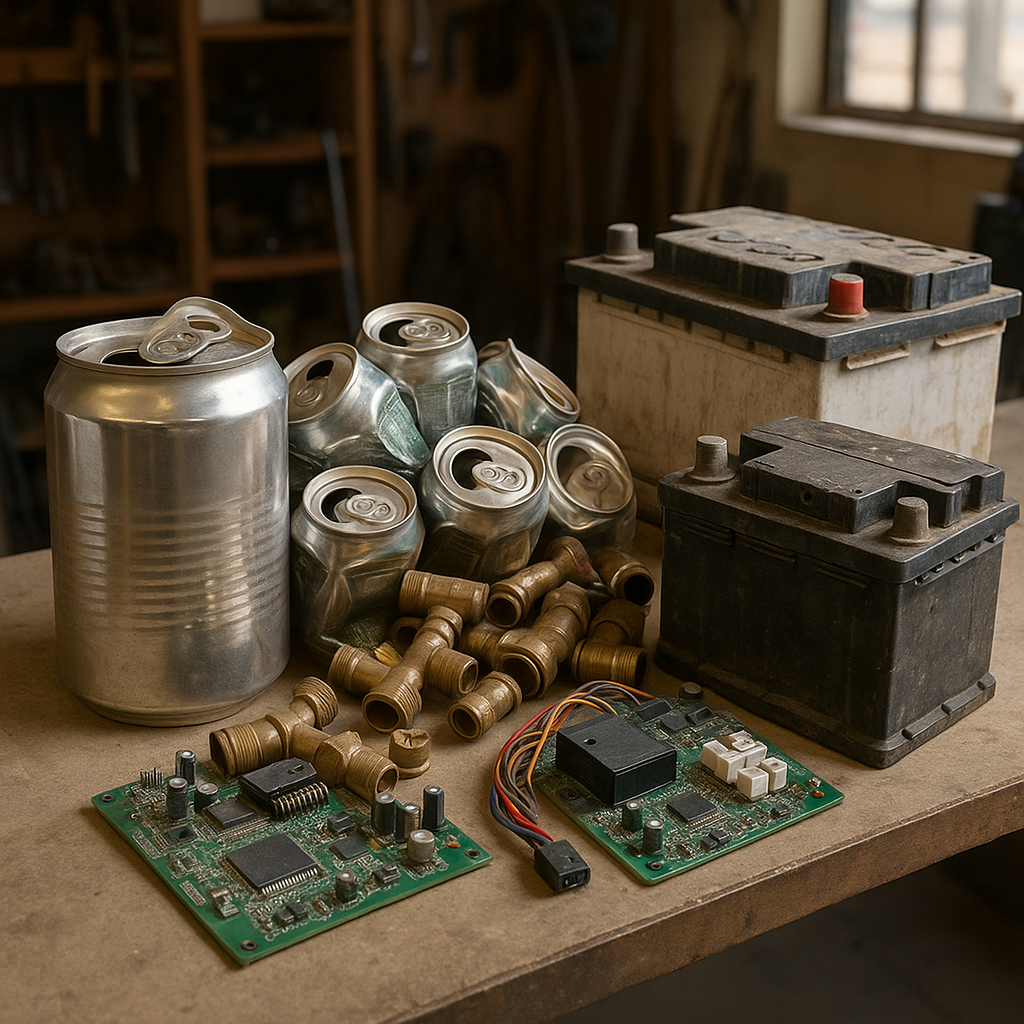

What Other Scrap Items Are Profitable to Recycle?

Brass: The overlooked copper alloy

Brass stands out as one of the most profitable non-ferrous metals after copper. This durable alloy of copper and zinc typically fetches a strong price per pound because of its density. Common sources include plumbing valves (“Red Brass”), doorknobs and faucets (“Yellow Brass”), and industrial fittings. Red brass, which has a higher copper content (approx. 85 percent), commands a higher price than yellow brass. Professional recyclers use XRF technology to differentiate these grades instantly.

Aluminum: Abundant and consistently valuable

Aluminum offers excellent profit potential due to its widespread availability. While individual beverage cans are light, the volume available makes aluminum a staple of the industry. Higher value, however, is found in “extruded” aluminum (window frames, clean structural tubing) and aluminum rims from vehicles. Aluminum recycling is an environmental powerhouse, saving 95 percent of the energy required to produce new metal from bauxite ore.

Stainless steel grades and their value

Not all stainless steel offers the same return on investment. The value of stainless is driven by its nickel content. Series 300 stainless (like 304 and 316) is non-magnetic and holds significant value. Series 400 stainless is magnetic and contains little to no nickel, making it worth considerably less. Using a simple magnet is the quickest way to separate high-value stainless from lower-grade iron alloys.

Carbide and high-temperature alloys

Often overlooked by the general public, tungsten carbide is one of the most valuable scrap items pound-for-pound. Used in machine shop drill bits, end mills, and industrial cutting tools, carbide is extremely dense and heavy. Specialized alloys like Inconel, Monel, and Hastelloy—common in the Texas oil and gas industry—are also incredibly valuable due to their high nickel and cobalt content.

Electronic waste: The urban mine

Electronic waste contains multiple valuable metals in concentrated forms. Computer motherboards, RAM modules, and processors contain recoverble gold, silver, and palladium. Hard drives provide aluminum casings and high-grade magnets. While individual units yield small amounts, bulk e-waste is processed through specialized shredding and smelting lines to recover these precious metals efficiently.

How Can You Maximize Your Scrap Metal Earnings?

Proper preparation transforms average scrap loads into profitable ventures. Recycling centers pay based on material quality and separation, so mixed metals are often priced at the lowest grade in the bin to cover the labor cost of sorting.

The magnet test

Begin with the magnet test to effectively separate your materials. Hold a magnet to each piece of metal; if it sticks, you have ferrous metals like steel or iron. If not, you’re likely holding more valuable non-ferrous metals such as copper, aluminum, or brass. This simple separation is the first step in upgrading your load from “shredder feed” to premium non-ferrous pricing.

Cleaning and preparation

Cleaning your scrap materials can significantly increase returns. “Cleaning” in the scrap industry means removing contaminants, not dirt. Remove insulation from copper wire to upgrade it from #1 Insulated to #1 Copper or Bare Bright. Strip plastic handles from brass valves and remove steel screws from aluminum frames. Research shows that removing contaminants can increase value by up to 30 percent. Even basic cleaning, like draining fluids from automotive parts, moves your materials into higher-paying categories.

Timing and quantity strategy

Timing can boost your earnings. Monitor market prices for various metals in your area, as scrap metal prices fluctuate daily based on global indices. Collecting larger quantities before visiting the recycling center often gives you leverage; many facilities offer better per-pound rates for bulk commercial sales. Organizing materials as you collect them—using separate bins for copper, brass, and aluminum—eliminates re-sorting time and allows for quicker unloading and payment.

What Key Factors Affect Scrap Metal Prices?

Scrap metal prices fluctuate dramatically, responding to multiple market forces simultaneously. A single economic shift can cause price changes of 15 to 20 percent within weeks, making this one of the most volatile commodity markets.

Global manufacturing demand drives significant price movements. When the construction and automotive sectors expand, they consume large quantities of recycled steel and copper. In 2026, the stabilization of the Chinese property sector and the industrial growth in India are major drivers of global metal consumption.

Currency exchange rates also impact prices since scrap metal trades globally in U.S. dollars. When the dollar strengthens against other currencies, international buyers face higher costs for American scrap, potentially softening domestic demand. Conversely, a weaker dollar often boosts exports.

Finally, the growing emphasis on circular economy principles is creating new demand streams. Companies seeking to meet Environmental, Social, and Governance (ESG) targets are increasingly specifying recycled content in their products, creating a “green premium” for high-quality recycled materials that meet strict environmental standards.

Conclusion: Turning Scrap Metal into a Valuable Resource

Recycling scrap metal offers a practical way to generate income while promoting environmental sustainability. Although market prices fluctuate daily, copper consistently remains the most valuable standard scrap metal you can collect, followed closely by brass and aluminum. By learning to identify different metals, preparing them properly, and utilizing advanced sorting technologies, you can transform everyday industrial waste into a significant financial resource.

Strategic scrap metal recycling benefits both your bottom line and the planet by generating sustainable income and reducing the need for destructive mining. For professional recycling services that utilize state-of-the-art technology to maximize the value of your materials, contact Okon Recycling at 214-717-4083.