5901 Botham Jean Blvd, Dallas, TX 75215

What Makes Copper a Widely Used Metal in Industry?

January 15, 2026Copper’s use-cases span a remarkable range of sectors. From the high-voltage electrical wiring in aerospace hangars to the water distribution systems in residential developments, the metal’s versatility is unmatched. It is found in everything from renewable energy storage to complex semiconductor components. Its combination of durability, workability and superior conductivity ensures it remains the preferred material choice for engineers.

Crucially, its complete recyclability allows it to be reused indefinitely, supporting the closed-loop manufacturing practices essential for the 2026 circular economy.

Why Is Copper Essential in Electrical and Electronic Applications?

Copper is the second most electrically conductive metal on the planet, exceeded only by silver. This impressive conductivity arises from the metal’s unique atomic structure, where freely moving valence electrons respond instantly to an electric field. The International Electrotechnical Commission has designated copper as the global benchmark for evaluating all other electrical conductors.

Superior Electrical Conductivity Properties

The metal’s low electrical resistivity of 1.68×10−8 Ω•m allows electricity to pass with minimal energy loss, which is vital for the efficiency of modern electrical distribution. While aluminum is often used in long-distance transmission lines due to its weight, it requires a 56 percent larger cross-sectional area to equal copper’s current-carrying capacity. In compact installations like data centers and urban skyscrapers, copper provides superior performance in a significantly smaller physical footprint.

Residential and Commercial Wiring Systems

In 2026, more than 60 percent of all refined copper is utilized in electrical applications, with building wire representing the largest market segment. The average American home contains nearly 200 pounds of copper wiring. In a professional recycling facility, this material is recovered as “Bright and Shiny” or “#1 Copper,” providing a high-value feedstock for secondary production. Its flexibility allows electricians to route wire through tight industrial conduits without fracture, and its resistance to “creep” prevents connections from loosening over time, significantly reducing fire hazards.

Industrial Electrical Components and Electronics

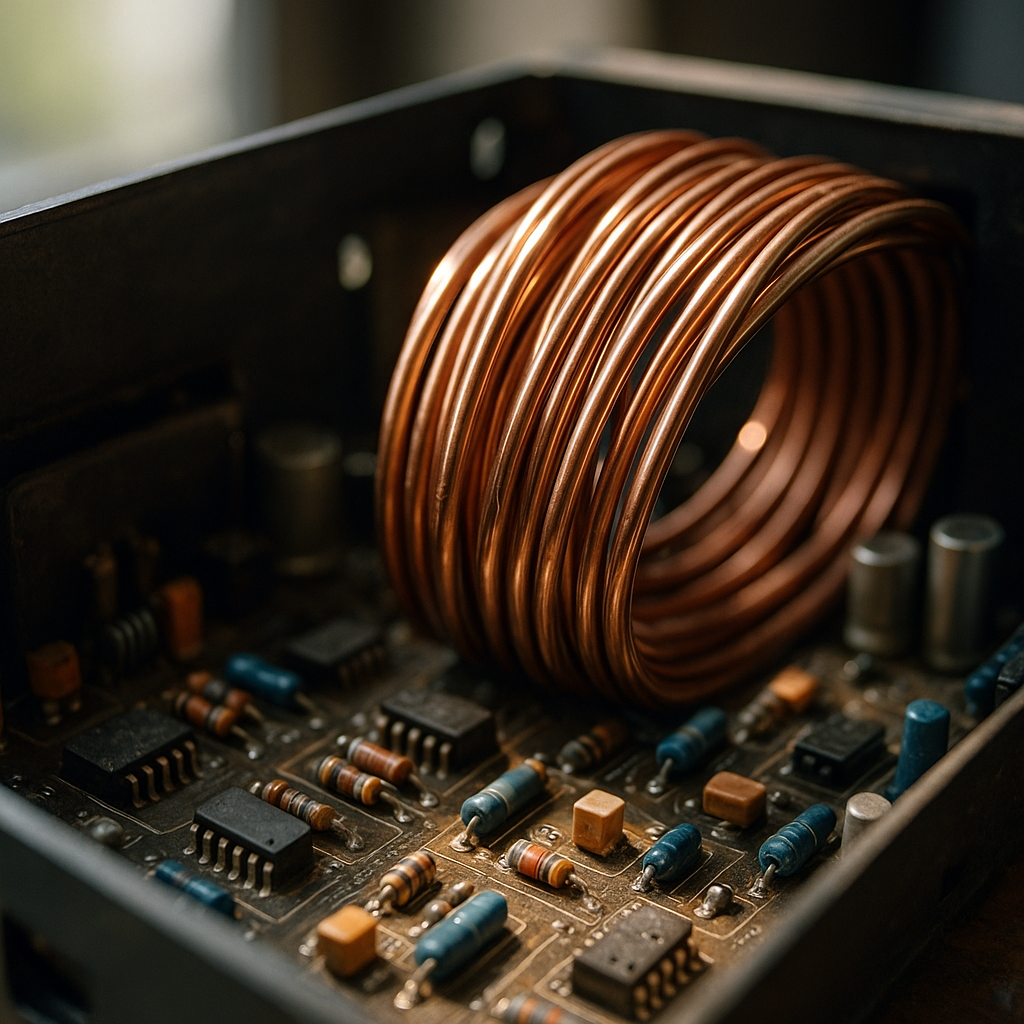

Heavy-duty applications rely on copper’s thermal and electrical qualities. Transformer windings utilize high-purity electrolytic-tough pitch copper for efficient high-voltage distribution. Modern electronics, from smartphones to AI-powered servers, depend on copper traces on printed circuit boards to carry precise electrical signals. Microchips use microscopic copper interconnects to link transistors within semiconductor devices, ensuring high-speed data transmission with minimal heat generation.

How Is Copper Used in Construction and Plumbing?

Copper serves dual purposes in modern construction as both a critical infrastructure component and a high-end architectural element. This versatility stems from a unique combination of functional and aesthetic properties that improve over time.

Potable Water and Antimicrobial Plumbing

In plumbing, copper continues to lead the market, with approximately 80 percent of all plumbing tubes in the United States made from this material. Copper pipes are the industrial standard for transporting potable water due to their antimicrobial properties. The metal naturally destroys harmful microorganisms on contact, preventing bacterial growth like Legionella within water distribution systems. This oligodynamic effect maintains water quality and reduces the risk of waterborne illness in high-occupancy building infrastructure.

Architectural Durability and Weathering

Architectural applications include roofing, gutters and downspouts that can provide reliable water management for more than a century. The material’s natural oxidation process creates a protective green patina (copper carbonate) that acts as a shield against further atmospheric corrosion. Unlike steel or iron, copper maintains its structural integrity when exposed to the extreme humidity of coastal regions or the arid heat of West Texas. This longevity explains why copper roofing is often reclaimed during demolition and processed as high-value “roofing copper” scrap.

Copper’s Role in the 2026 Energy Transition and Decarbonization

As we move through 2026, the global shift toward renewable energy and the decarbonization of heavy industry has transformed copper into a “strategic mineral.” Its role in the green energy transition is now the primary driver of the copper recycling market.

Wind and Solar Infrastructure

Renewable energy systems are incredibly copper-intensive. A single industrial-scale wind turbine requires approximately 3.6 tons of copper, primarily for the generator and the heavy-duty cabling required to bring power to the grid. Solar installations use copper for inverter components and the massive wiring networks that link individual panels. Industry data shows that renewable systems often require up to six times more copper than traditional fossil-fuel power plants to produce the same amount of electricity.

The “Urban Mining” of the Electrical Grid

To meet aggressive climate goals, the United States is currently undergoing a massive grid modernization effort. This involves replacing aging aluminum-core lines with high-capacity copper cables and installing thousands of new transformers. Professional recycling partners play a vital role here, facilitating “urban mining” by reclaiming the copper from retired grid infrastructure. Because recycled copper requires 85 percent less energy to produce than primary mining, every pound of recovered scrap directly lowers the carbon footprint of the new, greener electrical grid.

Artificial Intelligence and Data Centers

The boom in artificial intelligence has created an unexpected surge in copper demand in 2026. AI data centers require high-density power distribution and specialized cooling systems that rely on high-purity copper busbars and heat sinks. The rapid expansion of these facilities in North Texas has made industrial copper recovery from obsolete tech hardware a top priority for corporate ESG (Environmental, Social and Governance) targets.

Antimicrobial Health and Public Safety in 2026

Beyond its industrial utility, copper’s biological properties have gained renewed importance in public health settings. Research in 2026 has solidified copper’s role as a self-sanitizing material in hospitals and public transportation hubs.

Contact Killing of Pathogens

Metallic copper surfaces exhibit a phenomenon known as “contact killing.” Bacteria, yeasts and viruses are rapidly inactivated on copper surfaces through a process that causes oxidative stress and cell membrane rupture. Clinical trials have proven that Antimicrobial Copper® kills greater than 99.9 percent of pathogens within two hours. In modern healthcare facilities, replacing traditional stainless steel doorknobs, bed rails and IV poles with copper alloys has been shown to reduce hospital-acquired infection (HAI) rates by more than 50 percent.

Secondary Recovery of Medical Alloys

The specialized alloys used in medical settings, such as cupronickel, are high-value materials in the recycling stream. As medical facilities upgrade their equipment, professional recyclers ensure these alloys are separated from standard plumbing copper to maintain their specific metallurgical properties. This ensures that the antimicrobial benefits of the metal are preserved as it is melted down and recast into new safety-critical medical hardware.

Copper’s Role in Transportation and Industrial Machinery

Copper serves as the backbone of modern transportation systems and heavy industrial operations. The aerospace and automotive sectors rely on the metal for components that ensure safety and high-performance efficiency.

The Electric Vehicle Revolution

Electric vehicles (EVs) mark a historic shift in copper consumption. A typical EV contains about 83 kilograms of copper—nearly four times the amount found in a standard internal combustion engine vehicle. The largest portion is used in the lithium-ion battery system, inverters and high-speed motor windings. The rapid expansion of the Texas EV charging network also requires thousands of tons of copper for high-voltage power cables and grid upgrades.

Industrial Machinery Dependencies

Industrial facilities rely on copper for efficient energy transfer and heat management. Heat exchangers use the metal’s thermal properties to regulate temperatures in manufacturing and power generation. Electric motors, which power everything from conveyor systems to heavy industrial presses, incorporate dense copper windings. In a professional recycling program, these motors are processed to extract the “copper meat” from the steel housing, ensuring every gram of the conductive metal is recovered for the secondary market.

| Application | Standard System (est.) | Green/High-Tech Equivalent (est.) |

|---|---|---|

| Automotive | 50-60 lbs (Gasoline) | 180-200 lbs (EV) |

| Power Generation | 1 ton per MW (Coal) | 4-6 tons per MW (Wind/Solar) |

| Building Infrastructure | Standard Wiring | High-Efficiency Smart Grid Interconnects |

| Computing | Standard Desktop | AI-Optimized Server Rack (+30% Copper) |

Conclusion: The Future of Sustainable Copper Recovery

From the dawn of civilization to the high-tech innovations of 2026, copper remains an irreplaceable natural resource. Its superior conductivity, durability and antimicrobial properties make it the primary choice for the infrastructure that defines modern society. However, with global copper demand expected to double by 2035, the future of the industry depends on the efficient recovery of existing assets.

Recycling copper is the most effective way to ensure a stable supply for the energy transition while protecting our environment from the impacts of primary mining. By choosing a professional industrial partner to manage your copper scrap, you contribute to a multi-billion-dollar circular economy that conserves 85 percent of the energy required for metal production.

For expert guidance on copper recovery strategies, industrial scrap management and competitive market rates, contact Okon Recycling at 214-717-4083.