5901 Botham Jean Blvd, Dallas, TX 75215

What are Red Metals and Why are They Important for Recycling?

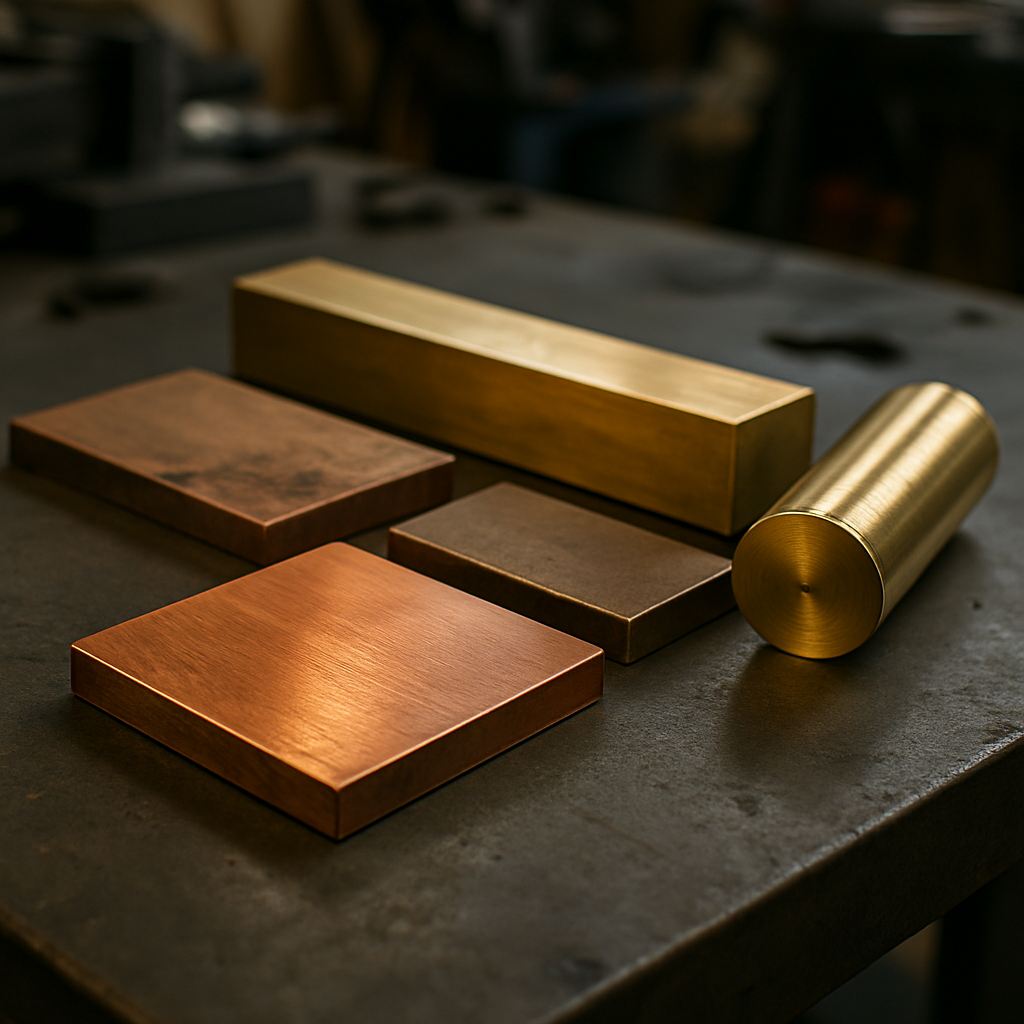

October 31, 2025Red metals are a family of copper-based alloys that include pure copper, brass, and bronze. These metals are known for their reddish-brown color and are fundamental to construction, electrical systems, plumbing, and manufacturing industries worldwide.

The unique properties of red metals make them invaluable. They offer excellent electrical and thermal conductivity, outstanding corrosion resistance, and remarkable durability. These attributes make them essential for everything from electrical wiring and water pipes to industrial machinery and decorative items.

In recycling, red metals are particularly prized. Unlike many materials that degrade during recycling, red metals can be recycled infinitely without losing their inherent qualities or performance. This perfect recyclability makes them key materials in sustainable waste management practices and the circular economy.

What are the Main Types of Red Metals?

Red metals are a notable category in the recycling industry, distinguished by their reddish hue and unique properties. The primary types are copper, brass, and bronze, each with characteristics that make them valuable across various applications.

Copper

Copper stands out as a pure elemental metal with a characteristic reddish-brown color. As the basis for other red metals, copper provides exceptional electrical and thermal conductivity, making it ideal for electrical wiring, electronics, and plumbing systems.

The metal’s natural antimicrobial properties offer unique advantages in healthcare settings, as copper surfaces can kill more than 99.9% of bacteria within two hours of contact. This self-sanitizing quality has increased its use on high-touch surfaces in hospitals and public spaces.

Copper is highly recyclable without losing its beneficial properties. Its excellent ductility and malleability allow it to be drawn into wires or formed into various shapes, enhancing its versatility in manufacturing processes.

Brass

Brass is an alloy primarily consisting of copper and zinc, with zinc content typically ranging from 5% to 45%. Higher concentrations yield a stronger and more pliable material. The specific ratio determines brass’s properties and color shade.

Featuring a bright, yellowish-gold appearance, brass is popular for decorative applications. It combines good corrosion resistance with excellent machinability, allowing easy formation into complex shapes.

Common applications include plumbing fixtures, musical instruments, and architectural elements. Its low friction properties make it suitable for lock mechanisms, gears, and bearings. Different formulations can be tailored for specific industrial needs by adjusting the zinc content or adding small amounts of other metals.

Bronze

Bronze is primarily an alloy of copper and tin, typically comprising about 88% copper and 12% tin. This composition results in a harder material than pure copper, with a distinctive reddish-brown color that develops a characteristic patina over time.

The addition of tin significantly enhances corrosion resistance, particularly against seawater, making bronze ideal for marine applications and outdoor sculptures that need to withstand harsh environmental conditions.

Bronze offers superior strength and durability compared to brass, making it valuable for industrial bearings, bushings, and components requiring low-friction properties. Its resistance to metal fatigue and wear makes it a staple in manufacturing heavy-duty equipment and precision parts.

| Red Metal | Main Components | Key Properties | Common Applications |

|---|---|---|---|

| Copper | Pure metal | High electrical and thermal conductivity, Antimicrobial properties | Wiring, Plumbing, Electronics |

| Brass | Copper and Zinc (5-45% zinc) | Good machinability, Corrosion resistance, Gold-like appearance | Plumbing fixtures, Musical instruments, Decorative elements |

| Bronze | Copper and Tin (about 88% copper, 12% tin) | High corrosion resistance, Low metal-to-metal friction | Marine hardware, Sculptures, Bearings |

The red metals family demonstrates how different compositions yield materials with distinctive properties while maintaining the core benefits of their copper base. Understanding these differences allows recyclers to sort and process these valuable materials efficiently, keeping them in the circular economy.

Each red metal type represents a balance between conductivity, strength, workability, and corrosion resistance, explaining their enduring importance from ancient times to modern industrial applications.

How is the Red Metal Recycling Process Carried Out?

The recycling of red metals such as copper, brass, and bronze is a methodical process that transforms discarded materials into valuable resources. This multi-stage approach ensures these metals can be reused without losing their essential properties, making them particularly valuable in the recycling stream.

Collection Phase

The process begins with the collection of materials from diverse sources. Scrap red metals come from construction sites, industrial facilities, electronics, plumbing fixtures, and residential waste. These valuable non-ferrous metals are rarely sent to landfills due to their high scrap value, making them prime candidates for recycling.

Common sources of red metal scrap include old wiring, electrical components, plumbing pipes, radiators, and various machinery parts. Electrical wiring and electronic devices are substantial sources of copper recycling, owing to the significant amounts of this highly conductive metal they contain.

Sorting Process

Once collected, the scrap undergoes sorting to separate different metal types. This crucial step ensures maximum recovery value since mixing metals can significantly reduce their worth. Sorting typically involves both manual inspection and technological methods.

Recyclers use magnets to quickly distinguish ferrous from non-ferrous metals, as red metals won’t stick to magnets. Color identification also helps separate copper (reddish) from brass (yellowish) and bronze (darker yellow to brown). More sophisticated recycling facilities use sensors and color differentiators to precisely identify metal types.

Cleaning Operations

After sorting, metals require thorough cleaning to remove contaminants like paint, dirt, oil, and other non-metallic materials. This step is crucial for ensuring high-quality recycled material.

The cleaning process may involve pressure washing, chemical treatment, or mechanical scrubbing. For copper wiring, insulation removal is necessary, often performed using specialized wire-stripping equipment. Removing impurities at this stage prevents contamination during melting and ensures the final recycled metal meets quality standards.

Processing and Transformation

The final stages transform the clean, sorted metals into reusable forms. Initially, the metals are shredded into smaller pieces to increase surface area, which improves melting efficiency. They are then melted in high-temperature furnaces, with each metal type processed at specific temperatures suited to its properties.

During melting, further purification occurs to remove any remaining contaminants. After purification, the molten metal is cast into ingots, bars, or sheets based on industry requirements. Once solidified, these standardized forms are ready for transportation to manufacturers who will use them as raw materials for new products.

The recycling of red metals significantly reduces energy consumption compared to primary production from ore. For instance, recycling copper requires up to 85% less energy than mining and processing new copper, while also reducing harmful emissions and conserving natural resources.

What are the Benefits of Recycling Red Metals?

Recycling red metals like copper, brass, and bronze offers significant benefits for both the environment and the economy. These valuable metals, unified by copper, can be recycled repeatedly without losing their properties or quality. Let’s explore the specific advantages of recycling these metals.

Environmental Benefits

The environmental impact of recycling red metals is profound. Mining for virgin copper and other metals disturbs vast areas of land, consumes excessive water, and uses substantial fossil fuel resources. Recycling, in contrast, helps conserve finite natural resources that would otherwise be depleted.

Recycling red metals greatly reduces carbon dioxide emissions, producing up to 95% fewer toxic gases than processing raw ore. This reduction is crucial in combating climate change and minimizing our overall carbon footprint.

Energy conservation is another key advantage. Processing recycled copper requires significantly less energy than extracting and refining virgin material. According to industry data, recycling copper can save more than 70% of the energy needed to mine it from ore, leading to reduced fossil fuel use and environmental impact.

- Reduces landfill waste by diverting valuable metals from waste streams

- Minimizes soil degradation and habitat loss caused by mining

- Decreases water pollution from mining operations

- Supports the development of a circular economy model

Economic Advantages

The recycling industry creates jobs at every stage, from collection and sorting to processing and manufacturing. Red metal recycling generates employment opportunities across various skill levels. The Institute of Scrap Recycling Industries estimates that recycling accounts for more than 500,000 jobs in the United States alone.

Businesses benefit from cost savings when using recycled metals. Manufacturing with recycled red metals is less expensive than processing primary ores, making products more affordable for consumers and stimulating economic growth.

Red metals hold significant value in the recycling market, providing financial incentives for individuals and businesses. Their high demand in construction, electrical work, and plumbing makes them consistently valuable. Scrap yards typically offer competitive prices for copper, brass, and bronze due to their versatility and adaptability.

Resource Conservation

Red metals are limited in supply. Recycling extends the usability of these materials across multiple product lifecycles. Recycling one ton of copper conserves approximately three tons of ore that would otherwise need to be mined, ensuring these valuable metals are available for future generations.

The demand for red metals continues to rise in our technology-driven economy. Recycling contributes to a more sustainable supply chain, reducing dependency on mining operations. This approach helps stabilize prices and ensure consistent availability of these crucial materials.

Recycling red metals offers a comprehensive solution. It protects the environment, strengthens the economy, creates jobs, and conserves valuable resources. Prioritizing recycling contributes to a sustainable future while meeting society’s material needs.

How Can Individuals and Businesses Participate in Red Metal Recycling?

Red metals such as copper and brass are valuable resources for recycling, and both individuals and businesses can contribute to their recovery. Engaging in red metal recycling not only yields economic benefits but also plays a crucial role in environmental conservation. Here’s how you can participate, whether you’re a homeowner or a business operator.

Household Red Metal Collection

Many homes have various sources of recyclable red metals. Look for items like old copper wiring from renovations, outdated plumbing fixtures, and non-functional small appliances. Even copper pots and pans are recyclable once they are no longer usable.

Electronics also provide significant sources of red metals. Old computers, televisions, and audio equipment contain copper wiring and components that can be reclaimed by recycling facilities. Instead of storing these items indefinitely or discarding them in landfills, set them aside for proper recycling.

Create a small collection area in your garage or storage space for red metal items until you gather enough for a trip to a recycling center. Even a small cardboard box is suitable for storing scraps of copper wire and small brass items.

Business Recycling Programs

Companies that generate scrap metal regularly can establish structured recycling programs to capture value from materials that might otherwise become waste. Construction companies, electrical contractors, plumbing businesses, and manufacturing facilities often produce significant amounts of recyclable metal scrap.

Start with a waste audit to identify sources and volumes of red metal waste in your operations. Place clearly labeled collection containers where scrap is generated, and train staff on proper sorting practices to prevent contamination and maximize the value of collected materials.

For larger operations, consider partnering directly with recycling facilities that provide collection containers and scheduled pickups. Some recyclers offer revenue-sharing arrangements, turning your waste stream into a modest income source while cutting disposal costs.

Finding the Right Recycling Partner

Whether an individual or business, finding the right recycling center is essential. Research local facilities that accept red metals and compare their pricing structures, as prices can vary significantly based on processing capabilities and market connections.

Consider factors beyond price when evaluating recyclers, such as location, hours, and whether they offer pickup services for larger quantities. Also, check if they require any special preparation of materials before acceptance.

Many recycling centers have websites listing accepted materials and current pricing. Some even offer price guarantees for business clients to protect against market fluctuations. Contact several facilities to compare services before deciding where to take your red metal scrap.

Preparing Your Red Metals for Recycling

Proper preparation of your scrap red metals can increase their value significantly. Recyclers pay more for clean, sorted materials that require minimal processing. Remove any attached non-metal components, like plastic insulation, wood, or rubber.

For copper wire, stripping the insulation exposes the valuable copper and substantially increases its value. While wire strippers make this easier, manual stripping with basic tools can be worthwhile for high-grade copper wire.

Sort red metals by type when possible. Separate pure copper from brass items and keep bronze components separately. This sorting helps recyclers process materials more efficiently and often results in better payment rates for your scrap.

Ensure safe transport of your materials. Sharp edges on cut metal can cause injuries, so use sturdy containers and wear gloves when handling scrap metal items.

Community Collection Initiatives

Beyond individual efforts, you might consider organizing community collection events. Neighborhood associations, schools, and religious organizations can coordinate red metal collection drives, making recycling more convenient for everyone and raising funds for community projects.

These collection events create economies of scale that might attract recyclers willing to offer better rates for larger volumes. They also provide an opportunity to educate community members about the importance of metal recycling and proper sorting techniques.

Businesses can sponsor such events as part of their corporate social responsibility programs, offering collection points, transportation assistance, or matching funds for any proceeds generated through the recycling effort.

Conclusion: The Circular Economy of Red Metal Recycling

Red metal recycling is a cornerstone of the circular economy, converting what was once waste into valuable resources that can be reused repeatedly without losing quality. This sustainable approach allows copper, brass, bronze, and other red metals to retain their utility indefinitely, creating a closed-loop system that benefits both the environment and the economy. The environmental advantages are significant—recycling red metals requires up to 85% less energy than primary production, significantly reduces carbon emissions, and minimizes the damaging effects of mining on natural landscapes and water resources.

The economic benefits are also impressive. The red metal recycling industry creates thousands of jobs, generates billions in economic activity, and provides manufacturers with cost-effective raw materials. As global demand for these metals continues to grow, especially in renewable energy technologies and electric vehicles, recycled red metals offer a sustainable solution that helps preserve finite resources for future generations. For your red metal recycling needs, contact Okon Recycling at 214-717-4083.