5901 Botham Jean Blvd, Dallas, TX 75215

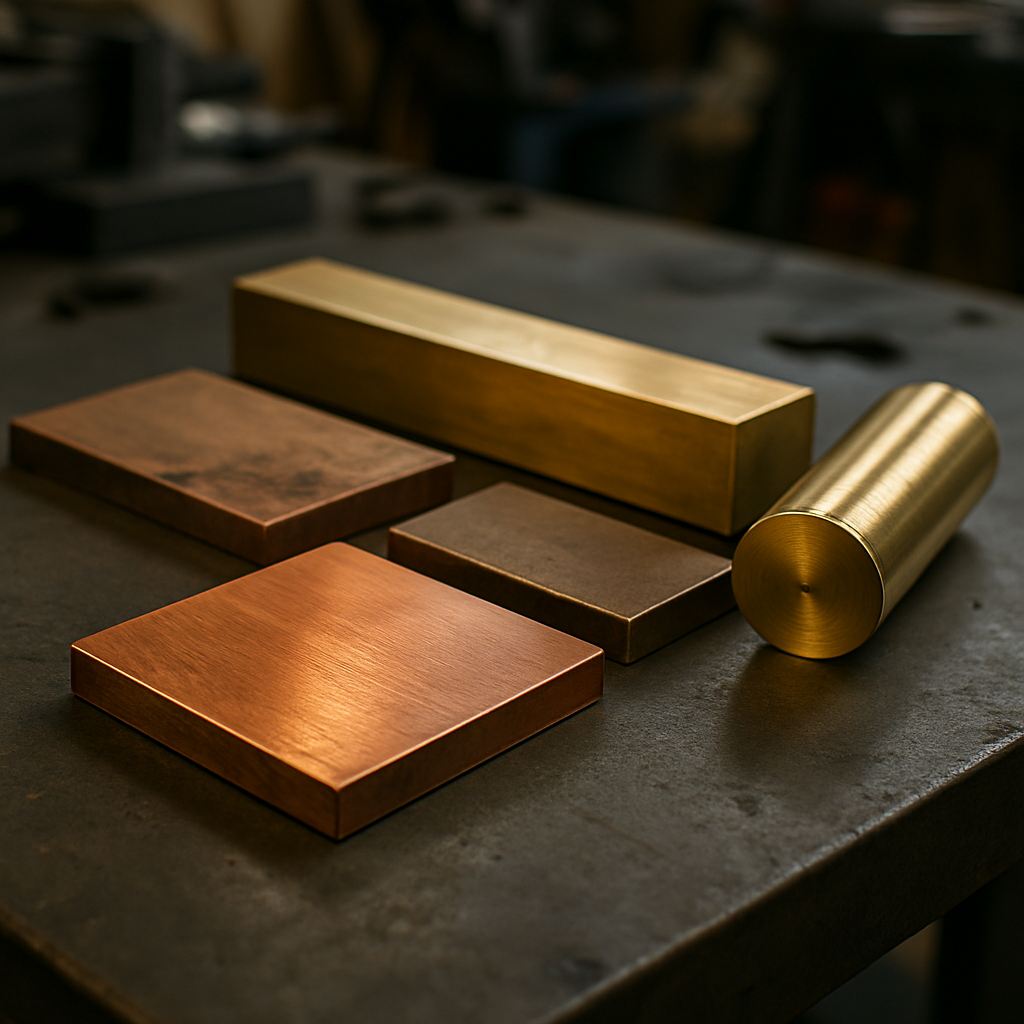

Copper vs Brass Price: 2026 Scrap Market Guide

January 9, 2026Knowledge of metal pricing directly affects recycling profitability and waste management decisions. Understanding copper vs. brass price differences is crucial for those involved in industrial scrap metal recovery or non-ferrous metals trading. The price gap between these two materials arises from fundamental composition differences that impact their market value, conductivity and processing requirements in early 2026.

Copper is a pure, naturally occurring metal found on the periodic table. In contrast, brass is a copper-zinc alloy, typically containing about two-thirds copper and one-third zinc. This composition difference explains why copper commands higher market prices than brass. The addition of zinc dilutes the pure copper content, creating a less valuable material from a raw materials perspective, although the resulting alloy offers superior machinability and corrosion resistance.

Current market conditions show copper prices reaching record levels due to the global energy transition, while brass prices maintain a steady but lower trading range.

What Factors Influence the Price of Brass?

The pricing of brass is influenced by several interconnected factors that recycling professionals must understand to optimize value recovery. The most significant driver is the alloy’s composition, particularly the copper-to-zinc ratio, followed by industrial demand cycles and logistics costs.

Raw Material Composition and Base Metal Prices

The copper-to-zinc ratio directly determines brass value in recycling markets. Red brass, containing approximately 85 percent copper, commands premium prices. Yellow brass, with about 60 percent copper, fetches lower rates. Because copper is the predominant component in most alloys, its market volatility is the primary driver of brass scrap values. A 20 percent increase in copper prices typically results in proportional brass price rises, affecting both procurement costs and scrap recovery revenues for manufacturers.

Industrial Demand and Market Sectors

The construction industry drives significant brass consumption, with a large portion of global brass production supporting plumbing, valves and architectural hardware. Economic growth in the residential and commercial sectors translates directly to higher brass demand. Furthermore, the automotive sector’s needs are expanding, particularly with electric vehicle (EV) development requiring specialized brass connectors. Regional industrial activity in North Texas significantly affects local brass markets, where robust manufacturing often leads to higher brass scrap prices due to lower transportation costs to regional mills.

Supply Chain and Global Economic Variables

Supply chain disruptions can increase brass prices by up to 15 percent when geopolitical events impact mining or transportation networks. Since brass trades primarily in U.S. dollars, currency strength affects international demand. A 10 percent dollar weakness can increase brass costs for foreign buyers, potentially altering export demand. Trade policies and tariff implementations also create price pressures, affecting both virgin material costs and recycled brass valuations.

Metallurgy 101: Distinguishing Red Brass from Yellow Brass

In the world of non-ferrous recycling, the color of the metal provides the first clue to its value. For industrial sellers, being able to identify the difference between “Red” and “Yellow” brass can mean a significant difference in the final payout at the scale.

Chemical Makeup and Corrosion Resistance

Red brass, often categorized under the C83600 alloy series, is highly prized for its resistance to “dezincification”—a form of corrosion where zinc is leached out of the alloy. Because it contains 85 percent copper and 5 percent each of tin, lead and zinc, it appears much darker and more “copper-like” than other alloys. This makes it the standard for heavy-duty plumbing valves and marine components that must withstand harsh environments. Yellow brass (C26000 series), containing up to 40 percent zinc, is much harder and appears bright, similar to gold. It is commonly used for shell casings, radiator cores and decorative hardware.

The File Test and Spark Test

Professional sorters often use a simple “file test” to verify the alloy. By filing a small section of the scrap metal, the underlying color becomes clear. If the shavings are deep red or orange, it is red brass. If they are bright lemon-yellow, it is yellow brass. Industrial managers can use this method to pre-sort materials before they reach the recycling facility, ensuring that high-purity red brass is not accidentally commingled with lower-value yellow brass, which would result in a lower “mixed brass” payout.

Advanced Sorting Technology: Precision Grading for Industrial Scrap

In 2026, the industrial recycling sector has moved beyond visual inspection. To provide the most accurate pricing for high-volume manufacturing clients, professional facilities utilize advanced metallurgical technology.

XRF Alloy Identification

Handheld X-ray Fluorescence (XRF) analyzers allow recycling technicians to determine the exact chemical composition of a piece of scrap in seconds. This technology is vital for identifying specialized brass alloys that may contain silicon or bismuth—materials used in modern “lead-free” plumbing mandates. By utilizing XRF technology, a professional recycler ensures that a facility is paid the true market value of its specific alloy, rather than a generic estimated rate. This precision is especially important for aerospace and defense contractors handling high-performance alloys.

Optical and Density Separation

For facilities processing shredded non-ferrous scrap, automated optical sorters use high-speed cameras and AI to separate copper from brass based on color and geometry. In larger operations, density separation (using air or water tables) can separate heavy red brass from lighter yellow brass and aluminum contaminants. This level of automation allows for the high-speed processing of thousands of pounds per hour, maintaining high purity levels in the resulting commodity streams that are then sold back to mills and foundries.

Which Is More Expensive: Copper or Brass?

Copper consistently commands higher prices per pound than brass in all market conditions. Current Bare Bright Copper is trading around $4.70 to $5.10 per pound in 2026, while standard brass grades are significantly lower. This price difference reflects copper’s superior electrical conductivity—nearly four times that of standard yellow brass—and its role as a critical mineral for global electrification.

Yellow brass typically sells for $2.20 to $2.70 per pound. Red brass commands higher rates due to its increased copper content, pricing between $3.10 to $3.60 per pound. Even at the red brass premium, it remains substantially less expensive than pure copper grades. Pure copper contains no alloying elements, making it ideal for electrical wiring and high-voltage power transmission. Brass, while providing durability and machinability at a lower cost, cannot match copper’s electrical properties.

The “Copper-to-Brass” Spread

Market data from professional recycling facilities shows that copper prices often run 75 percent to 125 percent higher than comparable brass grades. Clean copper tubing and #2 copper wire maintain this significant premium over brass alternatives. This is why proper sorting and cleaning are essential; even a small amount of brass contamination in a load of copper can lead to the entire load being “downgraded,” resulting in a loss of hundreds or thousands of dollars for a high-volume industrial seller.

| Material Type | Composition | Typical 2026 Price (Est.) |

|---|---|---|

| Bare Bright Copper | 99.9% Copper | $4.80 – $5.10 / lb |

| #1 Copper Tubing | 99% Copper | $4.50 – $4.75 / lb |

| Red Brass | ~85% Copper | $3.20 – $3.60 / lb |

| Yellow Brass | ~60% Copper | $2.30 – $2.75 / lb |

| Brass Shells | 70/30 Alloy | $2.20 – $2.50 / lb |

Regional and Logistics Factors

Processing requirements also influence the price differential. Copper recycling involves fewer steps since the metal maintains its purity through multiple cycles. Brass processing requires careful alloy analysis and the potential separation of zinc content, adding operational costs. While regional variations exist, urban markets with high industrial activity typically offer the most competitive rates for both metals. In North Texas, the density of manufacturing ensures that high-volume scrap generators have access to professional facilities with advanced weighing and analytical equipment.

Conclusion: Choosing Between Copper and Brass

Choosing between copper and brass involves balancing electrical conductivity, mechanical strength and cost. Copper’s superior conductivity makes it the only choice for high-performance power transmission and EV battery systems. On the other hand, brass offers enhanced machinability and corrosion resistance, making it the industrial standard for connectors, valves and precision fittings. For many applications where moderate conductivity suffices, the lower price of brass provides excellent value.

Whether managing electrical infrastructure upgrades or industrial equipment replacements, selecting the right metal and responsibly recycling your scrap is crucial for operational ROI and environmental stewardship.

For expert guidance on metal recycling and the sustainable disposal of copper and brass materials, contact Okon Recycling at 214-717-4083.