5901 Botham Jean Blvd, Dallas, TX 75215

What is Magnetic Cooling? Explained

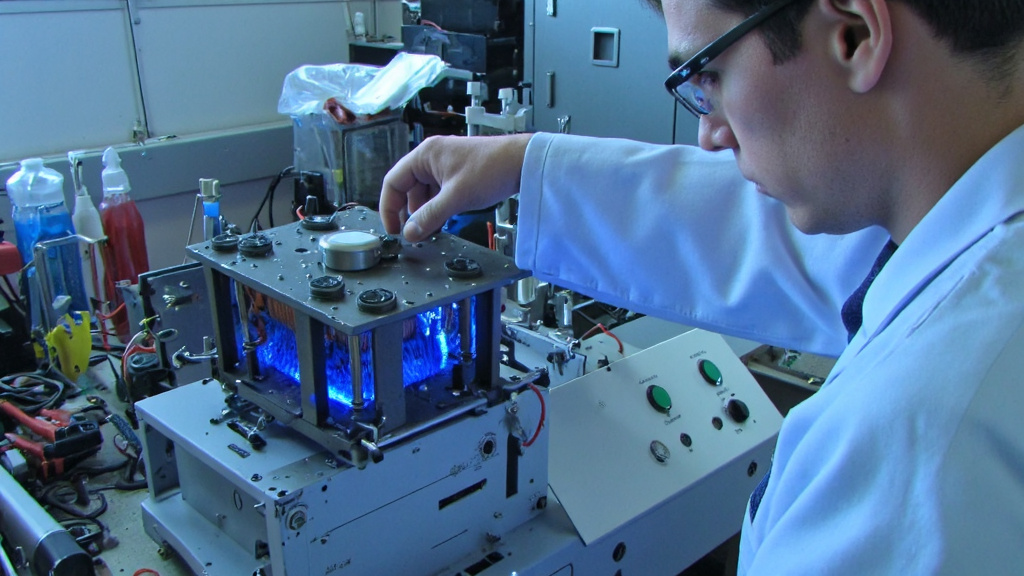

June 12, 2025Magnetic cooling is an innovative approach to refrigeration technology, utilizing the unique properties of specialized materials. This new method employs the magnetocaloric effect to induce temperature changes without traditional refrigerants or compressors. The process is straightforward yet powerful.

Magnetic cooling operates on a simple principle: certain materials heat up when exposed to a magnetic field and cool down significantly when the field is removed. This temperature change occurs because the magnetic field aligns the material’s magnetic domains, causing them to release heat. When the field is absent, the domains randomize and absorb heat from the surroundings.

What makes magnetic cooling particularly promising is its versatility across temperature ranges. The technology is effective from extremely low cryogenic temperatures (below -50°C) to above room temperature (+50°C). This flexibility allows for applications ranging from on-chip cooling solutions for electronic components to refrigeration in medical equipment and potentially household appliances.

How Does Magnetic Cooling Work?

Magnetic cooling utilizes the magnetocaloric effect, a scientific phenomenon that allows temperature changes without traditional refrigerants or compressors. This process involves special materials that alter their temperature in response to magnetic fields.

The magnetocaloric effect occurs when certain materials undergo temperature changes due to varying magnetic fields. When these materials are exposed to a magnetic field, they heat up, and when removed, they cool down. This principle is central to the magnetic refrigeration cycle.

The Four Stages of Magnetic Cooling

Magnetic cooling operates through a four-stage cycle for efficient refrigeration:

1. Magnetization: The cycle starts when a magnetocaloric material enters a magnetic field, aligning its magnetic moments with the field. This alignment reduces magnetic entropy, releasing heat and warming the material.

Similar to how iron filings align in a magnetic field, the magnetic dipoles in the material become ordered, releasing heat.

2. Adiabatic Demagnetization: After heat removal, the magnetic field decreases. In this insulated state, the material’s total energy remains constant. The magnetic moments absorb thermal energy to return to a random orientation, cooling the material below its initial temperature.

3. Heat Exchange: At this cooler temperature, the material absorbs heat from the space or substance needing cooling. This is similar to how traditional refrigerants absorb heat, but without harmful gases or compression.

4. Adiabatic Magnetization: Finally, the material returns to a magnetic field in an insulated state. The dipole alignment releases heat, completing the cycle and preparing the material for another cooling round.

Materials That Make Magnetic Cooling Possible

Not all materials exhibit a strong magnetocaloric effect suitable for cooling. Gadolinium and its alloys show significant temperature changes in magnetic fields near room temperature. Ongoing research aims to develop cost-effective, environmentally friendly, and efficient magnetocaloric materials.

Modern materials like manganese-iron-phosphorus-arsenic compounds and lanthanum-iron-silicon alloys provide promising alternatives that don’t rely on rare earth elements.

Advantages Over Traditional Refrigeration

Magnetic cooling offers several advantages over conventional vapor-compression refrigeration. It eliminates harmful refrigerants that contribute to ozone depletion and global warming. The system has fewer moving parts, potentially reducing maintenance needs and noise levels.

Magnetic refrigeration can achieve higher energy efficiency, with studies suggesting systems may operate 20-30% more efficiently than conventional methods, leading to significant energy savings.

The cycle can be continuously repeated to maintain cooling, with temperature changes depending on material properties and magnetic field strength. As research progresses, magnetic cooling may become a mainstream technology in everyday appliances.

What Are the Advantages of Magnetic Cooling?

Magnetic cooling technology offers a groundbreaking approach to refrigeration with significant advantages over conventional systems. The benefits extend beyond basic performance improvements to address key environmental and operational concerns.

Energy efficiency is perhaps the most compelling advantage of magnetic cooling systems. These innovative systems can achieve efficiency improvements of up to 30% compared to traditional vapor-compression refrigeration. This substantial gain comes from the direct conversion of magnetic energy to thermal energy, eliminating the inefficiencies associated with gas compression cycles.

The environmental benefits are noteworthy. Unlike conventional refrigeration that relies on hydrofluorocarbons (HFCs) and other harmful gases with high Global Warming Potential, magnetic cooling systems use solid refrigerants. These materials have zero Global Warming Potential and pose no threat to the ozone layer, making magnetic cooling a sustainable alternative in today’s climate-conscious world.

Operational advantages also make magnetic cooling attractive for various applications. The systems operate with significantly less noise due to their reduced number of moving parts. Traditional compressors, which generate most of the noise in conventional refrigerators, are eliminated in magnetic cooling systems, resulting in quieter operation ideal for noise-sensitive environments.

The design advantages extend to the system’s physical footprint. Magnetic cooling allows for more compact refrigeration units since they require fewer components than vapor-compression systems. This space efficiency makes magnetic refrigeration particularly valuable in applications where space constraints are a concern.

Maintenance requirements are substantially reduced with magnetic cooling technology. With fewer moving parts and no need for refrigerant recharging, these systems require less frequent servicing. This translates to lower long-term operating costs and improved reliability compared to conventional refrigeration systems.

Additionally, magnetic cooling systems demonstrate exceptional temperature control capabilities. The magnetocaloric effect allows for precise temperature adjustments, making these systems ideal for applications requiring exact temperature management, such as medical refrigeration or scientific equipment cooling.

The durability of magnetic cooling systems also deserves mention. Without the constant stress of compression and expansion cycles, components experience less wear over time. This extended lifespan further enhances the cost-effectiveness of magnetic refrigeration technology.

As research continues to advance in this field, magnetic cooling is poised to become an increasingly viable alternative to conventional refrigeration technologies across various sectors, from household appliances to industrial applications.

What Are the Current Applications and Future Potential of Magnetic Cooling?

Magnetic cooling technology is gaining traction across multiple sectors due to its energy efficiency and environmental benefits. This innovative approach to refrigeration operates effectively across a wide temperature range—from below -50°C to above +50°C—making it suitable for diverse applications.

Residential and Commercial Applications

In the residential sector, magnetic cooling shows promise for household appliances. Future refrigerators might run silently without compressors, using significantly less electricity than conventional models. This technology could reduce energy bills while eliminating the need for harmful refrigerants.

Commercial refrigeration is another key application area. Grocery stores and restaurants could adopt magnetic refrigeration systems to maintain food at optimal temperatures with greater efficiency. These systems offer lower maintenance requirements and operational costs, appealing to businesses focused on sustainability goals.

Retail cooling applications can particularly benefit from the compact design possibilities of magnetic cooling technology. The absence of bulky compressors allows for more streamlined display cases and storage units, maximizing valuable retail space while delivering reliable cooling performance.

Industrial and Medical Applications

Industrial cooling processes stand to gain substantially from magnetic refrigeration. Food preservation facilities and chemical processing plants can achieve precise temperature control with lower energy consumption. The elimination of refrigerant leaks also reduces maintenance concerns in industrial settings.

The medical field presents promising applications for magnetic cooling technology. Pharmaceuticals and biological samples require exact temperature maintenance for preservation. Magnetic refrigeration systems deliver the stability and precision needed for these critical applications while consuming less energy than conventional methods.

Temperature-sensitive medical equipment and laboratory settings benefit from the reduced noise of magnetic cooling systems. Without the operational sounds of compressors, these environments can maintain quieter conditions conducive to detailed work and patient comfort.

Future Developments and Integration

Looking ahead, integrating magnetic cooling with renewable energy sources presents exciting possibilities. Solar-powered magnetic refrigeration systems could provide cooling solutions in remote areas without reliable electricity access, further enhancing the environmental benefits of the technology.

Research into new magnetocaloric materials continues to advance the field. Future developments may yield more efficient materials that function optimally at different temperature ranges, expanding application possibilities. The search for materials beyond gadolinium—which is expensive and limited in supply—remains a priority for making magnetic cooling widely accessible.

Emerging markets show particular interest in magnetic cooling technology. As developing regions prioritize energy efficiency and environmental sustainability in their infrastructure development, magnetic refrigeration offers a forward-thinking solution to meet growing cooling demands while minimizing environmental impact.

The cryogenic field may also benefit from advances in magnetic cooling. Ultra-low temperature applications in quantum computing and superconductivity research could leverage magnetic refrigeration principles to achieve efficient cooling at extremely low temperatures.

As production scales up and costs decrease, magnetic cooling has the potential to revolutionize the entire cooling industry. From household refrigerators to specialized industrial applications, this technology offers a path toward more sustainable, energy-efficient temperature control across all sectors.

Ultimately, magnetic cooling represents more than just an alternative cooling method. It embodies a fundamental shift toward technologies that can satisfy our cooling needs while significantly reducing energy consumption and environmental impact.

| Temperature Range | Applications | Benefits |

|---|---|---|

| Below -50°C (-58°F) | Cryogenic cooling, Quantum computing, Superconductivity research | Efficient ultra-low temperature cooling without traditional refrigerants |

| -50°C to +50°C (-58°F to 122°F) | Domestic appliances, Commercial refrigeration, Industrial cooling, Ground source heat pumps | Energy efficiency improvements up to 30%, Zero GWP, Reduced noise |

| Around room temperature | Household refrigerators, Food preservation, Medical equipment, Pharmaceuticals storage | Precise temperature control, Lower maintenance requirements |

| Above +50°C (122°F) | Heat pumps, Industrial processes | Sustainable heating applications, Reduced environmental impact |

What Challenges Does Magnetic Cooling Face?

The journey toward the widespread adoption of magnetic cooling technology faces several significant hurdles, despite its promising environmental benefits. Material limitations are among the most pressing challenges in the field today. Current magnetocaloric materials function optimally within narrow temperature ranges, limiting their practical applications.

The efficiency of these materials decreases substantially at higher temperatures, creating a significant barrier for everyday applications like home refrigeration and commercial cooling systems. Scientists are actively researching alternative alloys and compounds that can maintain strong magnetocaloric effects across broader temperature ranges.

Cost remains another substantial obstacle in commercializing magnetic cooling technology. The rare-earth metals typically used in magnetocaloric materials, such as gadolinium and its alloys, are expensive and have limited availability. This makes initial implementation costs prohibitively high compared to conventional cooling systems that benefit from decades of manufacturing optimization.

The complex nature of magnetic cooling systems presents additional challenges. These systems require precise control of magnetic fields and sophisticated heat transfer mechanisms to function efficiently. The need for specialized components and engineering expertise further increases development costs and slows market entry.

Manufacturing scalability also poses difficulties. Current production methods for magnetocaloric materials are often lab-scale processes that don’t easily translate to mass production. Developing cost-effective manufacturing techniques that maintain material quality is a significant engineering challenge for industry stakeholders.

Despite these obstacles, researchers remain optimistic about magnetic cooling’s future. Research teams worldwide are developing new material compositions that show promising magnetocaloric effects without relying heavily on expensive rare-earth elements. Some experimental alloys based on more abundant elements like iron, manganese, and silicon have demonstrated encouraging results in laboratory settings.

System design innovations are simultaneously addressing efficiency challenges. Engineers are creating improved regenerator designs, optimizing fluid dynamics, and developing more powerful yet compact magnets. These advances aim to increase cooling capacity while reducing system complexity and cost.

Collaborative efforts between academic institutions and industry partners are accelerating progress through shared research initiatives. For example, a research team at the University of Cambridge recently developed a novel manganese-based alloy that demonstrates significant magnetocaloric properties at room temperature, potentially overcoming one key limitation of earlier materials.

Conclusion: The Future of Cooling Technology

Magnetic cooling represents a significant advancement in refrigeration technology. This innovative approach offers a substantial shift in cooling systems, providing up to 30% more energy efficiency than traditional methods, making it an attractive option for reducing power consumption.

The environmental advantages are equally noteworthy. By using solid-state magnetocaloric materials, magnetic cooling eliminates harmful refrigerants, resulting in a cooling solution with zero Global Warming Potential. Its adaptability across a wide temperature range, from below -50°C to above +50°C, makes it suitable for domestic appliances, commercial refrigeration, industrial cooling, and heat pumps.

For recycling and sustainability solutions, contact Okon Recycling at 214-717-4083. We assist businesses and municipalities in implementing environmentally responsible waste management solutions that align with emerging sustainable technologies like magnetic cooling.