5901 Botham Jean Blvd, Dallas, TX 75215

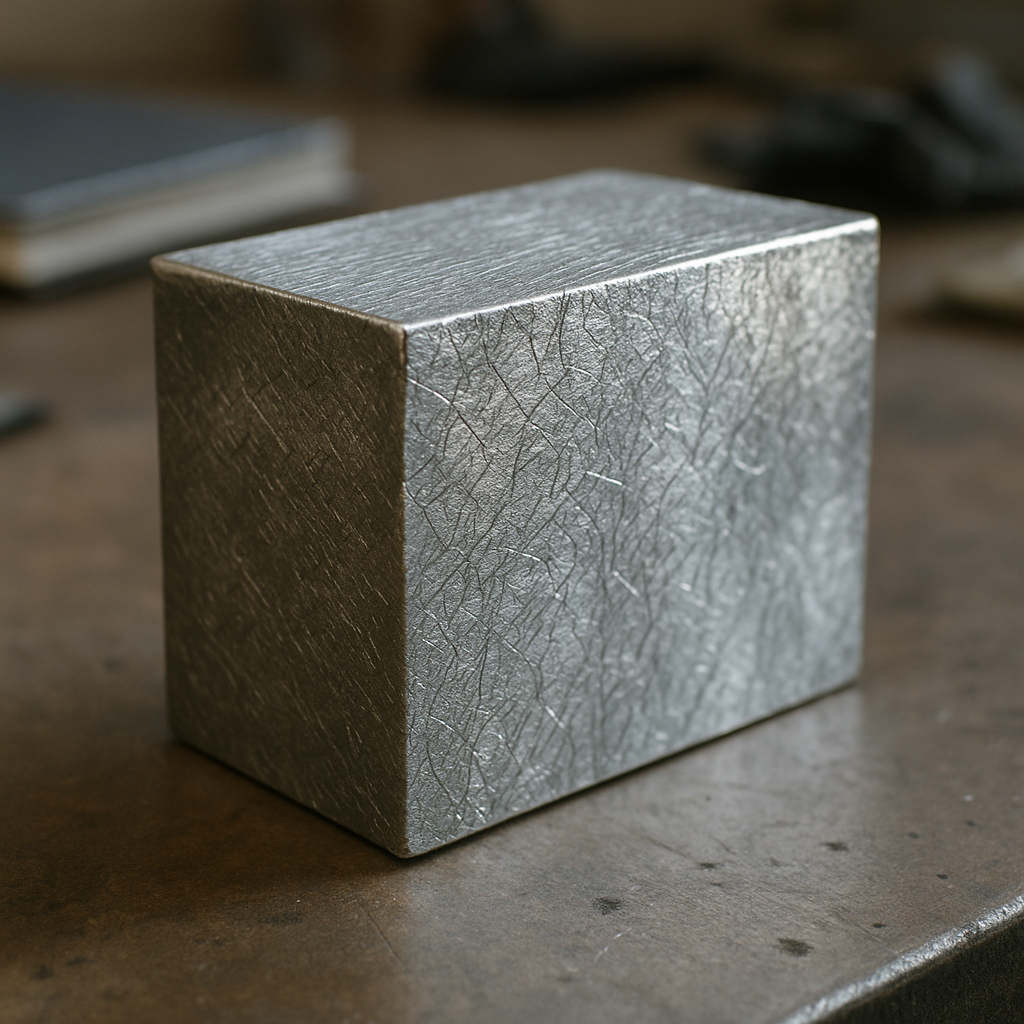

Answering the Essential Question: What is an Alloy?

June 4, 2025Alloys are formed when a primary metal, called the base metal, combines with additional elements to create a material with enhanced properties. The process starts with selecting metals based on characteristics like strength, corrosion resistance, or cost-effectiveness.

The most common method of creating alloys involves melting the base metal in specialized furnaces at high temperatures. Once liquid, other elements—metals like nickel or chromium, or non-metals like carbon—are added. This allows the elements to blend uniformly at the atomic level.

The liquid alloy mixture is then cooled and solidified into ingots, bars, or other forms for further processing. During cooling, atoms arrange into crystal structures that influence the material’s properties. The cooling rate is precisely controlled as it significantly affects the alloy’s characteristics.

How Are Alloys Made? From Melting Techniques to Advanced Methods

Here’s a breakdown of how alloys are made.

Melting and Mixing Methods

Modern alloy production uses several techniques to ensure proper mixing. Air melting is used for large-scale production, where slag protects the metal from oxidation. For more precise control and to minimize contamination, vacuum melting techniques are increasingly common. These methods allow manufacturers to closely monitor the composition and reduce unwanted oxidation.

During induction melting, the metal is heated in a crucible using electromagnetic fields. Arc melting uses an electric arc to melt metal droplets that fall onto a cooling platform where they rapidly solidify. Both techniques provide excellent control over alloy composition.

Powder Metallurgy

For alloys difficult to produce through traditional melting methods, powder metallurgy offers an alternative. This process begins with metal powders blended in precise proportions. The powder mixture is compacted under high pressure into a specific shape and then heated at temperatures below the melting point.

This sintering process causes the powder particles to bond, creating a solid piece with uniform composition. Powder metallurgy is useful for creating alloys with components that have vastly different melting points or would otherwise separate during cooling.

Cemented tungsten carbide cutting tools are a prime example of composite materials created through powder metallurgy rather than traditional melting techniques. These tools maintain their structure and properties even under extreme conditions.

Advanced Alloy Formation Methods

Ion implantation is a sophisticated method of alloy formation, involving bombarding a solid metal surface with high-energy ions to create a surface alloy. This process allows for precise control over the composition and depth of the alloy layer, making it valuable for applications where surface properties need modification without affecting the bulk material.

Mechanical alloying is another advanced technique where powders of different metals are mixed and ground together in high-energy ball mills. The repeated impact of the grinding media creates a solid-state alloying effect, allowing combinations that might be difficult to achieve through melting.

The specific method chosen depends largely on the elements being alloyed and the desired properties of the final material. Each technique offers different advantages in terms of control, scalability, and the ability to work with challenging element combinations.

What Are the Properties of Alloys?

Alloys possess unique properties that make them superior to pure metals in many applications. When elements combine to form an alloy, their atomic structures interact to create materials with enhanced characteristics beyond what any single metal can offer.

Increased strength is one of the most significant advantages of alloys. This occurs because different-sized atoms in the alloy disrupt the uniform atomic structure found in pure metals. Steel, an alloy of iron and carbon, demonstrates this perfectly. The carbon atoms position themselves between iron atoms, preventing layers from sliding past each other easily. This makes steel substantially stronger than pure iron, allowing it to support massive structures like bridges and skyscrapers.

Improved hardness goes hand-in-hand with increased strength. Alloys typically resist deformation and wear better than pure metals. Hardened steel alloys, for instance, maintain sharp cutting edges longer than tools made from unalloyed metals. This enhanced hardness extends the service life of alloy components in high-stress applications.

Superior corrosion resistance is another vital property of many alloys. Stainless steel, which contains chromium, forms a protective chromium oxide layer on its surface that shields the underlying metal from corrosion. This self-healing barrier makes stainless steel resistant to rust and ideal for outdoor applications. Similarly, brass (copper and zinc) resists corrosion better than pure copper, making it excellent for marine environments.

Alloys can also be engineered to handle extreme temperatures. Nickel-based superalloys maintain their structural integrity even at temperatures that would weaken or melt pure metals. This makes them essential in jet engines where components must withstand intense heat while maintaining strength.

Many alloys offer improved ductility and malleability compared to certain pure metals. Aluminum alloys, while stronger than pure aluminum, retain enough ductility to be formed into complex shapes for aerospace and automotive applications. The right combination of elements can create an alloy that’s both strong and workable.

However, alloys typically have lower electrical conductivity than pure metals. The same atomic disruptions that increase strength interfere with electron flow. Pure copper conducts electricity more efficiently than brass or bronze. Engineers must balance conductivity needs against other desirable properties when selecting materials for electrical applications.

The weight-to-strength ratio of alloys can be optimized for specific uses. Titanium alloys offer exceptional strength while remaining lightweight, making them ideal for aircraft components where weight reduction is crucial. This balance of strength and density allows for fuel efficiency without compromising structural integrity.

The manufacturing process significantly impacts alloy properties. Heat treatment, cooling rates, and mechanical processing all affect the final characteristics of an alloy. For example, rapidly cooling steel creates a harder but more brittle material, while slow cooling produces a softer, more ductile result.

Customization is perhaps the most valuable property of alloys. By adjusting the types and proportions of constituent elements, manufacturers can tailor alloys to meet specific performance requirements. This versatility makes alloys indispensable in modern engineering and manufacturing.

[[artifact_table]] Comparison of Key Properties: Alloys vs. Pure Metals [[/artifact_table]]What Are Common Types of Alloys?

Alloys form the backbone of modern industrial applications, each type offering unique properties that pure metals cannot provide alone. From everyday items to specialized equipment, alloys deliver enhanced durability, conductivity, and corrosion resistance, making them invaluable across multiple sectors.

Ferrous Alloys

Ferrous alloys contain iron as their primary component and are among the most widely used metal combinations in manufacturing and construction. These alloys offer exceptional strength and stability at relatively low cost.

Steel, a combination of iron and carbon (typically less than 2%), is the most common alloy in industrial applications. Its high tensile strength and relatively low production cost make it ideal for construction frameworks, automotive components, and infrastructure projects.

Stainless steel incorporates iron, chromium (at least 10.5%), and nickel to create a highly corrosion-resistant material. This versatile alloy appears in everything from kitchen sinks and appliances to surgical instruments and industrial equipment where exposure to moisture and chemicals is a concern.

Copper-Based Alloys

Brass, formed by combining copper (33-67%) and zinc (33-67%), delivers excellent electrical conductivity while remaining highly machinable. This golden-hued alloy commonly appears in decorative hardware, plumbing fixtures, musical instruments, and ammunition casings.

Bronze, an alloy of copper and tin, offers superior corrosion resistance, particularly in marine environments. Historical applications include sculptures and monuments, while modern uses extend to bearings, springs, and electrical connectors where durability matters.

Aluminum Alloys

Duralumin represents one of the most important aluminum alloys, combining aluminum with copper and small amounts of other elements. Its exceptional strength-to-weight ratio makes it crucial in aerospace applications, lightweight structures, and transportation equipment.

These aluminum-based alloys deliver the lightweight properties of pure aluminum while addressing its inherent softness. The addition of copper, magnesium, and other metals creates materials with significantly improved mechanical properties.

Specialty Alloys

Nickel alloys contain 72-83% nickel combined with other elements to create materials with outstanding electrical and thermal conductivity. These specialized alloys appear in electronic applications, transformers, and memory storage devices.

Sterling silver, composed of 92.5% silver and 7.5% copper, represents a jewelry-grade alloy that balances pure silver’s luster with improved durability. This precious metal alloy remains popular for decorative items, tableware, and ornamental pieces.

Dental amalgam combines mercury with silver, tin, and copper to create durable fillings for dental restoration. While controversial due to mercury content, this alloy has served dentistry for generations due to its durability and ease of application.

Why Are Alloys Important?

Alloys are a fundamental cornerstone of modern industry and technology. By combining different metals or adding non-metals to base metals, manufacturers create materials with enhanced properties that pure metals cannot achieve. These materials offer strength, durability, and corrosion resistance, driving innovation across various sectors.

The significance of alloys lies in their versatility and adaptability. From the structural steel supporting skyscrapers to the lightweight aluminum alloys in aircraft, these engineered materials enable many of the products and structures we rely on daily. Their ability to be tailored for specific applications makes them invaluable for addressing unique industrial challenges.

For businesses and municipalities aiming to responsibly manage metal waste and recover valuable resources, proper recycling of alloys is essential. Contact Okon Recycling at 214-717-4083 for specialized recycling solutions that ensure these valuable materials remain in the circular economy.