5901 Botham Jean Blvd, Dallas, TX 75215

Do Solar Panels Have Any Scrap Value? Explore Recycling

February 8, 2026Silver is the most valuable material recovered from scrap solar panels on a per-pound basis. Though it makes up only 0.05% of a panel’s total weight, silver accounts for about 14% of the total material value in crystalline silicon panels. In early 2026, the solar industry uses over 15% of global silver supplies and is projected to consume nearly all available supply within two decades, making recovered silver an increasingly precious commodity in the global market.

Aluminum is another highly valuable scrap metal in solar panel recycling. The aluminum frame surrounding most panels provides substantial recovery value due to its quantity and consistent market demand. According to the World Bank, aluminum used in solar panels is a primary driver of climate impacts among transition minerals, making its recovery environmentally significant beyond its monetary value. High-volume industrial recyclers prioritize these frames for their high purity and ease of processing into secondary billet.

Copper components within solar panels offer considerable value for recycling operations. Found in wiring systems and internal connections, copper commands strong market prices and remains easily separable during the recycling process. The metal’s consistent demand across the electronics, automotive, and renewable sectors ensures a stable value for recovered copper from decommissioned arrays. Silicon also represents one of the most technically valuable materials despite recycling challenges. As the core semiconductor material, recovered silicon requires intensive processing to achieve solar-grade purity, translating into significant value when refined to manufacturing specifications.

How Is the Value Recovered From Scrap Solar Panels?

Value recovery from scrap solar panels follows a systematic dismantling and separation process designed to extract the highest purity from each component. This process transforms what was once considered “end-of-life” waste into high-grade raw materials ready for reintroduction into the global manufacturing supply chain. In 2026, automation has significantly increased the speed and accuracy of these recovery efforts.

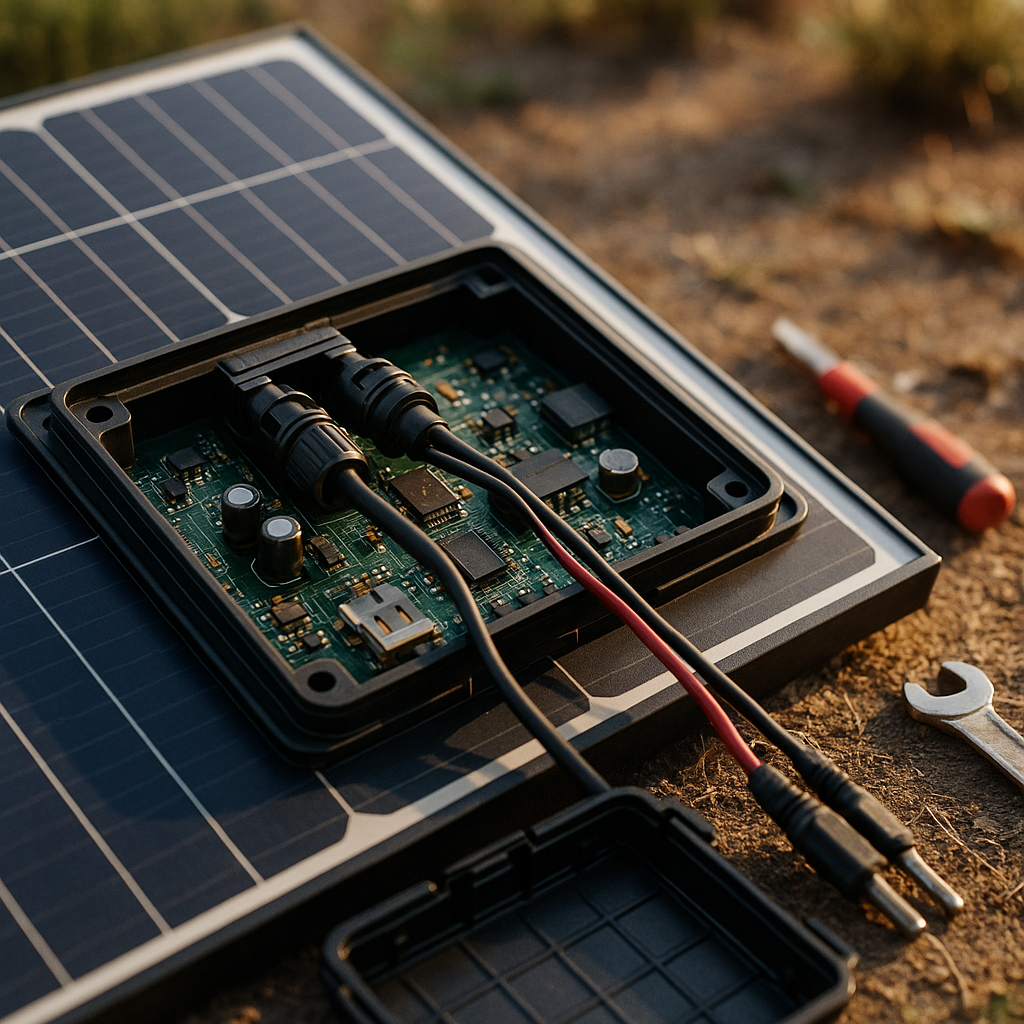

The recycling process begins with initial dismantling steps that target the most accessible and valuable components. Technicians first remove the aluminum frame, which constitutes a significant portion of recoverable weight. Next, the junction box is removed, which contains high-value copper wiring and electronic components. These parts are directed to specialized non-ferrous processing lines where they are graded and prepared for smelting.

Glass and silicon wafer separation

After removing external components, recyclers focus on separating the glass from the silicon wafer assembly. This step requires specialized equipment because the materials are bonded with ethylene-vinyl acetate (EVA) encapsulant designed to withstand decades of outdoor exposure. Advanced facilities use automated tools to separate the glass layer from the underlying laminate without contaminating the material streams. This ensures the recovered glass can be used for high-value applications rather than just being “downcycled” into construction aggregate.

The separation process employs thermal, mechanical, or chemical methods depending on the panel type. Thermal processing involves heating panels to approximately 500°C to break the encapsulant bonds. Mechanical processes use physical force and specialized cutting tools to separate layers, while chemical methods dissolve specific bonds while preserving the structural integrity of the silicon wafers. Each method has specific advantages regarding material purity and energy efficiency.

Material recovery and purification

The remaining laminate undergoes shredding to break it into manageable pieces for further refinement. This shredded mixture contains silicon cells, encapsulant materials, and backing sheets that require separation through multiple specialized techniques. The process isolates different material streams, including plastics, silicon, and precious metals. Advanced recycling facilities in North Texas can recover up to 95% of a panel’s original value through these sophisticated separation processes.

Silver recovery remains the greatest technical challenge due to the microscopic quantities present on each cell. However, because it represents such a large portion of the financial value, facilities invest in electrochemical and chemical leaching processes to extract silver flakes. The final purification stage cleans recovered materials to meet manufacturing specifications, such as acid etching for silicon to remove impurities and prepare it for semiconductor applications.

The 2026 Solar Supply Crunch: AI and Silver Demand

As we navigate the industrial landscape of 2026, the demand for solar-grade silver has reached an all-time high. This surge is not only driven by the expansion of solar farms but also by the massive growth in Artificial Intelligence (AI) data centers, which compete for the same high-purity silver used in electrical contacts.

The “Electrification super-cycle”

The global transition to electric infrastructure has created a “super-cycle” for precious and transition metals. Solar panels are no longer just energy generators; they are mobile mines of silver and copper. In early 2026, the price of silver has hit historic highs, making the “urban mining” of decommissioned panels more profitable than ever. For a facility manager or utility operator, this means that an old solar array is a liquid asset that can offset the cost of new high-efficiency module upgrades.

Supply chain security and domestic reshoring

With global geopolitical shifts impacting the mining of new materials, the U.S. manufacturing sector is prioritizing domestically sourced recycled content. By recycling solar panels locally in North Texas, manufacturers secure a steady stream of “Green Silver” and “Green Silicon” that is not subject to international trade volatility or high shipping costs. This reshoring of raw material supply is a critical component of 2026 energy policy, making local recycling centers the new backbone of the renewable energy economy.

Navigating New 2026 Texas Solar Recycling Regulations

Operating a solar recycling program in 2026 requires strict adherence to updated state and federal mandates. Staying compliant is essential for protecting your organization from legal liability and ensuring a transparent audit trail for corporate sustainability reporting.

Texas HB 3228 and decommissioning bonds

Texas state law now requires large-scale solar project owners to provide financial assurance—often in the form of a decommissioning bond—to ensure that panels are not abandoned at the end of their life. Under 2026 updates, these bonds are tied to “Certificates of Recycling” provided by authorized facilities. This means that simply hauling panels to a landfill is no longer a viable legal option for commercial or utility-scale operators. Working with a professional recycling partner ensures that your project remains in good standing with the Texas Commission on Environmental Quality (TCEQ).

Material traceability and ESG reporting

In 2026, major corporations are required to provide detailed material traceability as part of their Environmental, Social, and Governance (ESG) disclosures. Professional recycling centers now offer digital “Cradle-to-Cradle” tracking, providing data on the exact tonnage of glass, aluminum, and silver returned to the market. This transparency allows asset owners to prove their commitment to the circular economy, enhancing their brand value and satisfying the requirements of institutional investors who prioritize sustainable supply chains.

What Is the Future Economic Potential of Solar Panel Recycling?

The economic prospects for solar panel recycling represent one of the fastest-growing sectors in industrial waste management. According to the International Renewable Energy Agency, the global value of recoverable raw materials from end-of-life panels is expected to reach $450 million by 2030. This is enough raw material to produce approximately 60 million new panels, drastically reducing the environmental footprint of the next energy generation.

Industry analysis suggests the total recyclable materials market for PV modules could approach $2.7 billion by 2030, with long-term forecasts reaching $80 billion by 2050. This growth reflects the massive wave of early 2000s-era panels that are currently reaching their end-of-life status. By 2035, recycling could supply 21% of the world’s silver and 11% of the aluminum needed for the solar industry, effectively closing the loop on manufacturing.

Regional economic impacts in Texas

Texas is uniquely positioned to benefit from this economic boom due to its massive utility-scale solar capacity. North American markets project over $1.5 billion in recoverable material value. These regional concentrations create significant opportunities for specialized infrastructure development and the creation of “green-collar” jobs in materials processing and chemical refinement. In North Texas, the proximity of manufacturing hubs allows recycled materials to be transported and reintegrated into new products with minimal logistical overhead.

Conclusion: Unlocking the Hidden Value in Solar Panels

The real value of solar panels as scrap lies not in their whole form, but in their individual constituents. Silver, aluminum, copper, and semiconductor-grade silicon can be efficiently recovered through advanced industrial processes, transforming what was once a waste stream into an economically viable resource. With silver alone accounting for the highest per-pound value and global supplies tightening, recovering these materials is vital for both financial returns and national supply chain security.

This strategy creates a circular solar economy where retired panels serve as the inputs for the next generation of energy manufacturing. The dual benefits of financial return and environmental sustainability make solar panel recycling a profitable and responsible choice for 2026. For comprehensive recycling solutions that maximize material recovery from your end-of-life solar arrays, contact Okon Recycling at 214-717-4083.