5901 Botham Jean Blvd, Dallas, TX 75215

The Common Uses for Aluminum: A Quick Guide

January 24, 2026Aluminum is a versatile and abundant metal with a vast range of applications across numerous industries. Its primary uses are driven by its unique properties, including being lightweight, strong, corrosion-resistant, and an excellent conductor of heat and electricity. These characteristics make it a valuable material in transportation, packaging, construction, consumer goods, and electronics.

What makes aluminum particularly valuable is its combination of strength and lightness. At roughly one-third the weight of steel while maintaining impressive durability, aluminum allows engineers to create products that perform better with less material. This lightweight metal also forms a natural oxide layer that provides exceptional corrosion resistance, making it ideal for outdoor and marine environments in the Texas Gulf Coast where other metals would quickly deteriorate.

How Is Aluminum Used in Major Industries?

Aluminum’s presence in the global market is defined by its ability to adapt to high-stress environments while remaining economically viable for mass production. In 2026, the integration of recycled aluminum into these sectors has become a mandatory component of many corporate sustainability strategies.

Transportation applications

Aluminum dominates the transportation sector due to its exceptional strength-to-weight ratio. In aviation, aluminum makes up 70 to 80 percent of aircraft components, allowing engineers to construct lightweight planes that can withstand operational stresses. This leads to better fuel efficiency and greater payload capacity, which is vital for the thriving aerospace hub in North Texas.

The automotive industry uses aluminum in engine castings, wheels, radiators, and increasingly in body panels and structural components. Modern vehicles include an average of 250 pounds of aluminum per car, up from 100 pounds a decade ago. By replacing steel parts with aluminum, manufacturers achieve up to a 50 percent weight reduction in specific components, which is crucial for extending the range of electric vehicles (EVs).

Rail transportation benefits from aluminum’s attributes as well. Aluminum freight cars weigh one-third less than their steel counterparts, allowing for more cargo and reducing energy consumption. High-speed trains extensively use aluminum to minimize weight and enhance aerodynamic efficiency, a trend that continues to grow as Texas explores new rail infrastructure.

Packaging industry applications

Aluminum is an excellent barrier material in packaging. Its impermeability to moisture, air, and light preserves food quality and extends shelf life. The material effectively seals and protects contents from environmental contamination, making it a staple in the pharmaceutical and food sectors.

Beverage cans are a prominent example, using about 5 billion pounds of aluminum annually in the U.S. market. Aluminum foils and food containers offer similar protective benefits while maintaining the taste and aroma of packaged products. The material’s corrosion resistance ensures it does not alter the flavor of beverages or foods, and its non-toxic properties make it safe for direct food contact.

Construction and building applications

The construction industry values aluminum for its durability, aesthetic appeal, and minimal maintenance needs. Window frames, roofing systems, and siding applications benefit from aluminum’s corrosion resistance and long lifespan, particularly in harsh urban environments. As of January 2026, recycled aluminum content is a primary driver for projects seeking Leadership in Energy and Environmental Design (LEED) certification.

Structural applications span doors, railings, skylights, and curtain wall systems. Aluminum can be cut, welded, and molded into complex shapes, providing architects and designers with unmatched creativity. Its lightweight nature reduces structural load requirements and installation costs, which is especially beneficial for high-rise developments in Dallas and Houston.

Electrical and electronic applications

Aluminum’s electrical conductivity is valuable for power transmission systems and electronic applications. While copper is superior in raw conductivity, aluminum offers a better balance of electrical performance and structural strength for overhead transmission lines. Its reduced weight results in lower support structure requirements and installation costs for the Texas power grid.

Electronic devices use aluminum for heat sinks and thermal management components. Its thermal conductivity effectively dissipates heat, protecting sensitive components in smartphones, laptops, and data center servers from overheating. This extends device lifespan and maintains optimal performance in high-demand computing environments.

What Key Properties Make Aluminum So Versatile?

Aluminum’s remarkable versatility arises from a unique combination of physical and chemical properties. These characteristics enable manufacturers to create products that are both lightweight and durable while maintaining excellent performance standards. Furthermore, these properties make aluminum “infinitely recyclable,” meaning it can be processed and reused without any loss of quality.

Lightweight yet strong construction

Aluminum has a density of approximately 2.71 grams per cubic centimeter, making it about one-third the weight of steel. This low density directly contributes to improved fuel efficiency in vehicles and reduced transportation costs globally. Its impressive strength-to-weight ratio allows engineers to design structures that maintain structural integrity while minimizing mass.

This lightweight nature is particularly advantageous in industrial recycling operations. Transportation costs for aluminum scrap are lower than those for heavier metals, making collection and processing more economically viable. The reduced weight also means less energy consumption during the sorting and mechanical handling phases at the recycling facility.

Natural corrosion protection

When exposed to oxygen, aluminum naturally forms a thin protective oxide layer. This aluminum oxide coating provides exceptional corrosion resistance, protecting the underlying metal from environmental degradation. Unlike steel, which requires heavy coatings or galvanized treatments, aluminum’s self-protecting nature significantly reduces long-term maintenance needs.

Aluminum’s durability allows products to be recycled multiple times without losing their protective qualities. This benefit is evident in North Texas processing operations, where decades-old industrial siding or automotive components maintain their essential metal quality through repeated recycling cycles, even after exposure to the elements.

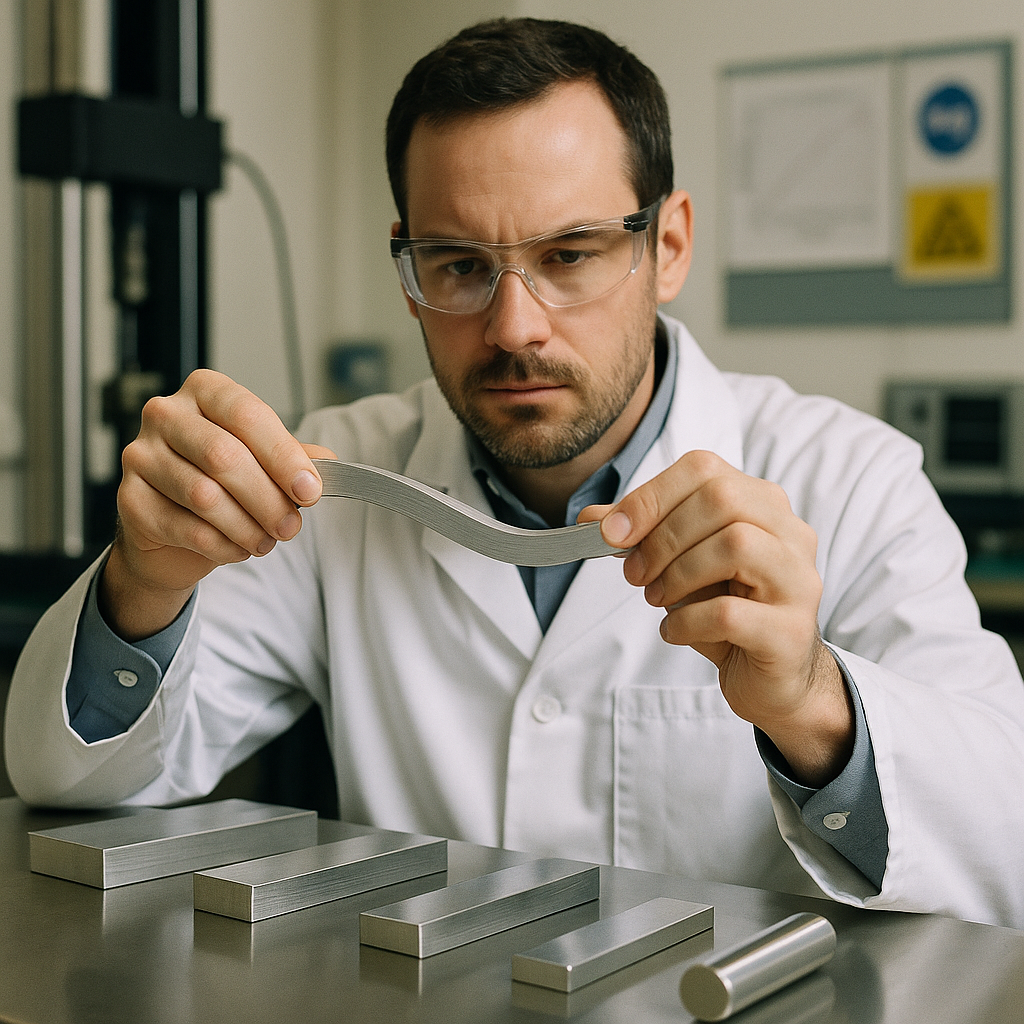

Superior formability and workability

Aluminum’s high ductility and malleability allow it to be easily shaped into complex forms without cracking. This metal can be extruded, rolled, stamped, and drawn into intricate designs that would be impossible with less flexible materials. This formability advantage also applies to recycling; aluminum scrap can be efficiently melted and reformed into new products without degrading its fundamental properties, supporting circular economy principles.

Advanced Industrial Trends: Aluminum in 2026

As we move through 2026, aluminum has moved beyond its role as a simple structural material. It is now a cornerstone of high-tech innovation, particularly in the fields of additive manufacturing and renewable energy.

Aluminum in 3D printing and additive manufacturing

One of the most significant shifts in the industry is the rise of aluminum powders for 3D printing. Additive manufacturing with aluminum alloys allows for the production of complex, bespoke parts that were previously impossible to cast or machine. This process drastically reduces material waste, as manufacturers only use the specific amount of aluminum needed for the component. Industries such as aerospace and defense are currently using this technology to cut production times for large aircraft components from years down to months.

Electrification and green energy infrastructure

Aluminum is the “linchpin” material for the global energy transition. It is essential for the chassis and battery housings of electric vehicles, where its lightweight nature directly translates to longer battery range. Additionally, aluminum extrusions are the primary material for solar panel frames and racking systems. As Texas continues to expand its solar capacity, the demand for high-strength, corrosion-resistant aluminum alloys is expected to reach record highs by the end of 2026.

Maximizing the Value of Industrial Aluminum Scrap

For Texas businesses, aluminum scrap is a valuable asset that can generate significant revenue if handled correctly. In early 2026, the average price for aluminum scrap in Texas yards reached approximately $0.60 to $0.65 per pound, with clean, high-grade materials fetching the highest premiums.

Strategies for scrap preparation

To receive the best rates at the scale, industrial facilities should implement “source separation.” This involves keeping different aluminum alloys separate at the point of generation. For example, “Clean Aluminum Sheet” should not be mixed with “Painted Siding” or “Cast Aluminum.” Removing non-metal contaminants like plastic, rubber, or wood is also essential. Recyclers often pay significantly more for “clean” scrap that requires no additional processing before it enters the furnace.

Utilizing technology for grading

Professional recycling facilities now use X-ray fluorescence (XRF) and Laser-Induced Breakdown Spectroscopy (LIBS) to verify the exact chemical composition of aluminum alloys. For a factory generating specialized aerospace scrap, this technology ensures that high-value alloys—such as those containing lithium or scandium—are priced accurately. Businesses should look for a recycling partner that offers this level of transparency and technical precision.

Does Using Aluminum Have Any Disadvantages?

Aluminum’s softness presents notable challenges in handling and durability within waste management operations. The metal is prone to dents and scratches during collection and processing. This susceptibility can complicate recycling efforts, as damaged pieces may require extra cleaning to remove surface contaminants before reuse.

The material’s lower strength compared to steel results in structural limitations in heavy-duty applications. Although aluminum offers a favorable strength-to-weight ratio, it cannot always endure the same mechanical stresses as steel in high-load industrial settings. Consequently, more aluminum is often required to achieve similar structural performance, which can increase the volume needing eventual recycling.

Corrosion vulnerabilities pose specific challenges despite aluminum’s general resistance. The metal can corrode in highly acidic or alkaline conditions. Galvanic corrosion is particularly problematic when aluminum comes into contact with other metals like copper or steel in mixed waste streams, accelerating deterioration and reducing material recovery quality.

Energy-intensive primary production also makes aluminum more expensive to produce than steel. However, the environmental case for recycling is undeniable: recycling aluminum uses 95 percent less energy than producing it from raw bauxite ore. This massive energy savings translates directly into a 90 to 95 percent reduction in greenhouse gas emissions, making the recycling of this metal one of the most effective ways for a business to reduce its carbon footprint.

The Enduring Value of Aluminum

Aluminum is a versatile material that combines high performance with environmental responsibility. Its lightweight nature, strength, and corrosion resistance make it indispensable in modern construction, manufacturing, and consumer products. From automotive components that improve fuel efficiency to architectural systems that boost building performance, aluminum meets both functional and aesthetic demands.

As industries prioritize sustainable practices, aluminum is the recyclable metal of choice for forward-thinking manufacturers. With over 75 percent of all aluminum ever produced still in use today, it represents the future of responsible industrial sectors.

Aluminum’s infinite recyclability, requiring only 5 percent of the energy needed for primary production, positions it as a cornerstone of the circular economy. Contact Okon Recycling at 214-717-4083 to maximize the value of your recyclable materials while supporting environmental sustainability.