5901 Botham Jean Blvd, Dallas, TX 75215

Solar Panel Disposal in Irving: 2026 Texas Recycling Guide

January 21, 2026Texas has officially surpassed California as the nation’s leader in solar power capacity. The American Clean Power Association confirms this milestone, placing the Lone Star State at the forefront of renewable energy development. However, this rapid growth brings an unexpected challenge that Irving businesses and municipalities must address: the inevitable decommissioning of aging infrastructure.

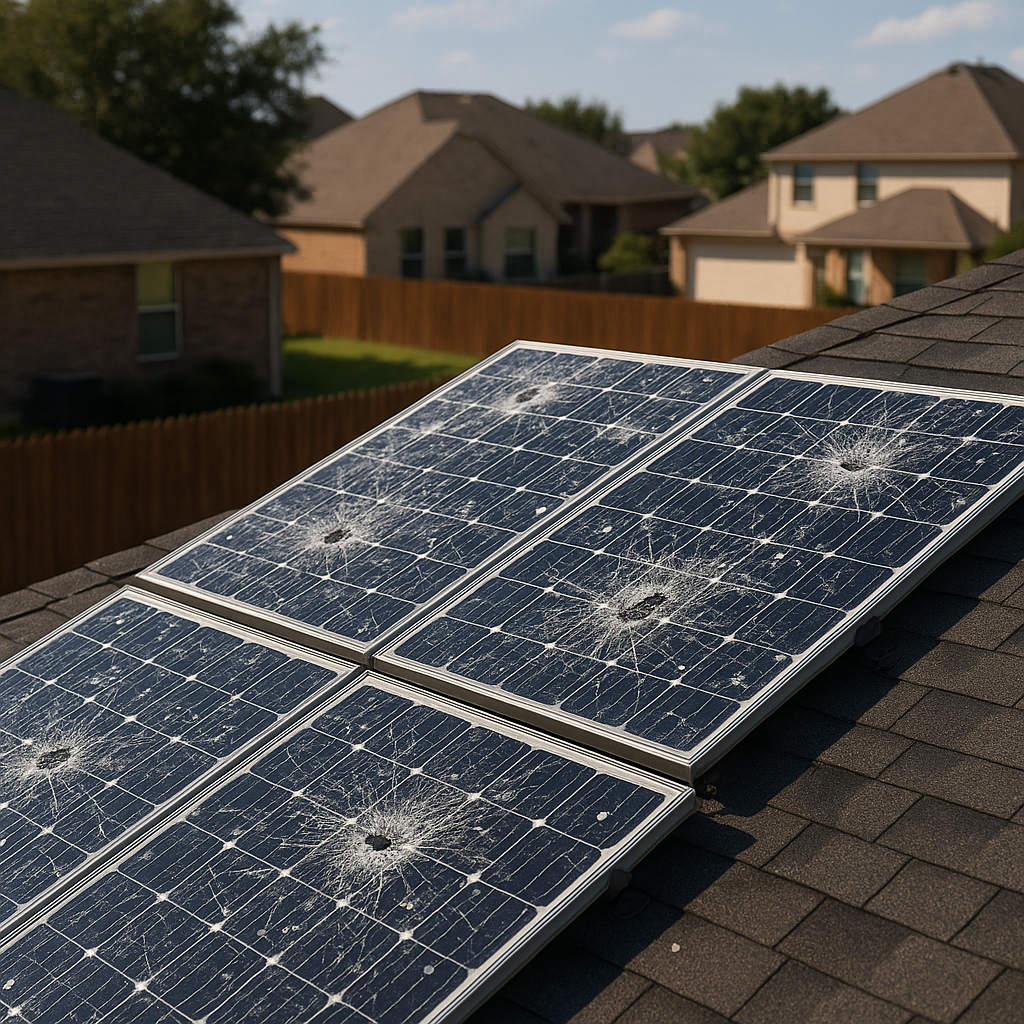

Solar panels installed during the early 2000s solar boom are reaching the end of their 25 to 30 year lifespan. These end-of-life panels create urgent waste management concerns across Irving and the greater Dallas-Fort Worth area. Historically, nearly 90 percent of decommissioned solar panels nationwide ended up in landfills, wasting billions of dollars in recoverable materials and potentially releasing substances like lead and cadmium into soil and groundwater. In 2026, new state mandates have transformed how these assets must be handled.

Commercial solar operators now face significant legal liabilities if panels are improperly disposed of. Under updated Texas Commission on Environmental Quality (TCEQ) regulations, responsible recycling is no longer just an ethical choice—it is a statutory requirement for new installations. Companies prioritizing environmental stewardship through proper solar panel disposal in Irving, Texas, can position themselves as sustainability leaders while supporting ESG goals and corporate responsibility initiatives.

What Regulations Govern Solar Panel Disposal in Texas?

The Texas Commission on Environmental Quality (TCEQ) is the primary state authority overseeing solar panel disposal. In 2025 and 2026, the regulatory landscape shifted dramatically with the implementation of new laws, including House Bill 3228 and House Bill 3229. These mandates require solar facility owners to plan for decommissioning before construction even begins.

Mandatory Recycling and “Recycle-First” Policies

New 2025 guidelines from the TCEQ encourage a “recycle-first” hierarchy. Under HB 3228, solar project lessees are required to reuse or recycle all components that are “practicably capable of being reused or recycled.” This prevents thousands of tons of glass, silicon, and aluminum from occupying valuable landfill space. Decommissioned panels must be shipped to authorized recycling facilities that meet strict environmental processing standards.

Universal Waste Classification

Most decommissioned solar panels from commercial installations fall under the “universal waste” category. This federal and state classification simplifies the regulatory process compared to hazardous waste designations, allowing for easier storage and transportation. However, this does not eliminate compliance obligations. The universal waste framework requires Irving businesses to follow strict protocols for collection, storage duration limits, and proper labeling during transport to certified facilities.

Financial Assurance and Annual Reporting

Effective January 15, 2026, recycling facilities that accept renewable energy components must submit annual reports to the TCEQ. These reports must include a complete inventory of all unrecycled components on-site. Furthermore, HB 3229 requires solar developers to provide financial assurance—such as a bond or letter of credit—to cover the full cost of decommissioning and recycling. This ensures that landowners and taxpayers are not left with the financial burden of “orphaned” solar panels.

Documentation and Record-Keeping Obligations

Strict documentation is essential for Texas solar panel disposal compliance. Businesses must maintain comprehensive records, including manifests, bills of lading, and quantities of components recycled. Recycling certificates are a critical compliance document, providing official proof that panels were processed at an authorized facility. Companies should retain these documents for auditing and ESG reporting to demonstrate their commitment to a circular economy.

What Is the Process for Recycling Commercial Solar Panels in Texas?

Commercial solar panel recycling in Texas follows a systematic approach to maximize material recovery. The process begins with a comprehensive inventory assessment of all decommissioned panels at your facility. This step involves cataloging panel specifications, quantities, and current condition to determine the most effective recovery strategy.

Businesses must partner with a certified commercial recycler qualified to handle solar panel waste. In North Texas, professional facilities utilize advanced de-manufacturing techniques to extract maximum value from every unit. The recycling process typically recovers over 90 percent of a panel’s weight, turning potential waste into industrial-grade raw materials.

Transportation and Safe Disassembly

Safe removal and transport of solar panels require specialized handling to prevent glass breakage and the release of internal materials. Certified recyclers utilize trained technicians skilled in proper disconnection and secure packaging methods. Once panels arrive at the facility, technical processing begins with the removal of the aluminum frame and the plastic junction box. These components are highly recyclable and are processed through existing metal and plastic streams.

Advanced Material Recovery Techniques

After the frame is removed, the “sandwich” of glass, silicon cells, and polymer backing is processed. Advanced facilities use thermal, mechanical, or chemical processes to separate these layers. For example, “hydrogen processing” or thermal treatment can be used to remove the polymer encapsulant, allowing the silicon wafers and silver contacts to be recovered. This high-purity recovery ensures that precious metals and silicon can be used to manufacture new high-tech components.

The Economic Value of Solar Asset Recovery

While recycling is a regulatory necessity, it also offers significant economic benefits through asset recovery. In the industrial landscape of 2026, end-of-life solar panels are viewed as “urban mines” rich with valuable materials that can offset the costs of decommissioning.

Reclaiming Precious and Base Metals

Solar panels contain significant quantities of silver, copper, and high-purity silicon. Silver, used in the conductive paste of solar cells, is particularly valuable. When processed at scale, the recovery of these precious metals provides a revenue stream that can reduce the overall net cost of a recycling contract. Additionally, the aluminum frames recovered from a large solar farm represent tons of high-grade metal that can be sold back into the commodity market.

Secondary Markets and Repowering

Not all decommissioned panels must be ground down for raw materials. “Repowering” projects—where older panels are replaced with newer, more efficient models—often yield panels that still have 10 to 15 years of functional life. Professional recycling partners in Irving can conduct rapid testing to identify panels suitable for the secondary market. These panels can be resold for off-grid applications or small-scale commercial use, providing a higher return for the original asset owner while supporting the highest tier of the circular economy: reuse.

Sustainable Energy Storage: Recycling Solar Batteries and BESS

As Irving continues to develop as a hub for renewable energy, the focus is expanding beyond the panels to include Battery Energy Storage Systems (BESS). These large-scale lithium-ion battery installations are critical for grid stability but present their own unique recycling challenges.

Managing Lithium-Ion and Lead-Acid Systems

Most modern solar installations utilize lithium-ion technology, which the EPA and TCEQ have recently moved toward classifying as hazardous waste in certain industrial contexts. Professional recycling facilities in the Dallas-Irving metropolitan area are expanding their capabilities to include the collection, dismantling, and sorting of these advanced battery systems. By recovering lithium, cobalt, and nickel from spent BESS units, Texas recyclers are securing the materials needed for the next generation of electric vehicle (EV) and grid-scale batteries.

Compliance for Energy Storage Decommissioning

Similar to solar panels, BESS installations now fall under updated decommissioning requirements. Texas HB 3809 (2025) specifically mandates that project lessees remove and recycle all battery facility components, including transformers and underground cables. This comprehensive removal ensures the land can be returned to its original condition, protecting landowners and the environment. Partnering with a recycler who understands these new battery-specific mandates is essential for any firm operating energy storage assets in North Texas.

Are There Solar Energy and Recycling Resources Based in Irving, Texas?

Irving serves as a strategic hub for renewable energy development and advanced recycling operations. The city hosts the corporate headquarters for major industry players shaping the future of clean energy. This local presence ensures that businesses in the DFW Metroplex have access to world-class expertise in project lifecycle management.

Renewable Energy Development in Irving

Irving is a key center for renewable energy project development, with local headquarters managing more than 10 GW of projects globally. These firms are increasingly incorporating decommissioning plans into their projects from the planning stage. This proactive approach ensures that solar panels and energy storage systems are handled responsibly at the end of their 20 to 30 year operational life, typically through partnerships with local industrial recyclers.

Regional Battery and Metal Recovery Leadership

Irving’s proximity to Dallas and Denton County places it at the center of the world’s most advanced recycling infrastructure. The region is home to some of the largest battery recyclers in the world, processing millions of units annually. This closed-loop infrastructure allows for the recovery of 99 percent of materials in lead-acid batteries and is rapidly scaling to meet the demand for lithium-ion recovery.

Local industrial recycling centers provide the scale needed for high-volume solar projects. By utilizing rail links and major airports in the Dallas-Fort Worth area, these facilities can efficiently collect feedstock from across the United States and process it right here in Texas. This minimizes the carbon footprint of the recycling process itself by reducing transportation distances for the state’s massive solar inventory.

Conclusion: Adopting Sustainable Solar Panel Disposal in Irving

As the solar industry in Texas continues to evolve, responsible end-of-life management is essential. For businesses in Irving, partnering with certified recyclers to ensure compliant disposal is no longer optional under the 2026 regulatory framework. This approach prevents legal liabilities, enhances ESG credentials, and ensures that Texas remains a leader in clean energy through a truly sustainable lifecycle.

The advantages of proper solar panel disposal go beyond regulatory compliance. Certified recycling processes can recover up to 95 percent of a panel’s value, turning potential environmental waste into a domestic source of glass, aluminum, and silver. Irving businesses should incorporate these sustainable practices into their long-term operations.

For a customized decommissioning and recycling plan that meets all TCEQ requirements, contact Okon Recycling at 214-717-4083.