5901 Botham Jean Blvd, Dallas, TX 75215

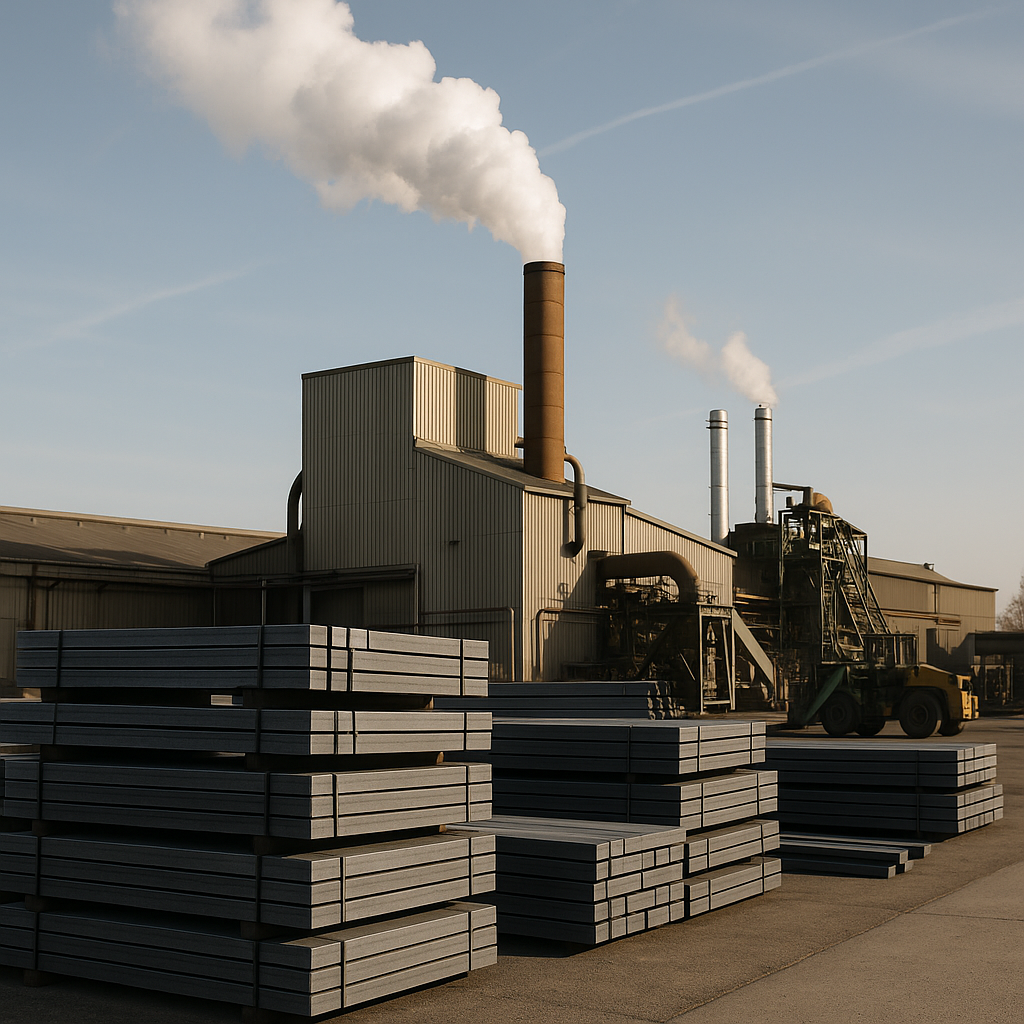

#1 Prepared Steel Recycling: Maximizing Scrap Value with ISRI Specs and Quality Control

December 10, 2025Not all scrap steel commands the same price at the recycling yard. The difference lies in proper classification and preparation. #1 prepared steel represents the highest grade of ferrous metals accepted by steel mills, commanding premium scrap metal prices due to its ready-to-process condition.

#1 prepared steel recycling involves processing scrap steel that meets specific industry standards for thickness and dimensions. According to the Institute of Scrap Recycling Industries (ISRI), this category includes any steel over 1/4 inch thick that measures 5 feet long or shorter and 3 feet wide or smaller. This specification ensures the material can move directly into electric arc furnaces without additional processing, making it highly valuable to steel manufacturers.

This classification system plays a crucial role in the circular economy by maximizing resource efficiency. Steel maintains 100% of its inherent properties when recycled, allowing it to be reused indefinitely in a closed-material loop.

What Are the Specifications for #1 Prepared Steel?

#1 prepared steel is one of the most valuable grades of ferrous scrap metal in the recycling industry. The specifications for this category are carefully defined to ensure efficient processing and high-quality steel production. Understanding these requirements helps facilities maximize recovery value while meeting mill expectations.

The dimensional requirements for #1 prepared steel may vary slightly among steel mills, but industry standards typically specify maximum dimensions of 5 feet by 18 inches. Some facilities accept smaller maximum dimensions of 3 feet by 18 inches, while others may accommodate up to 5 feet by 24 inches based on their charging equipment capabilities.

Thickness specifications are a core quality parameter for this grade. All #1 prepared steel must have a minimum thickness of 1/4 inch. This heavy gauge distinguishes it from lighter scrap categories and ensures the density needed for efficient furnace operations. Most facilities specify a maximum thickness ranging from 2 to 4 inches to prevent charging difficulties.

Density requirements usually mandate a minimum of 50 to 70 pounds per cubic foot, depending on the receiving facility’s specifications. This density standard ensures the material provides adequate furnace yield and maintains proper heat distribution during melting operations. Higher density materials generally command premium pricing due to their superior processing characteristics.

Quality standards for #1 prepared steel require the material to be free from excessive rust, non-ferrous metals, and contaminating substances. The scrap must consist of clean wrought iron or steel that moves freely through conveyor systems without jamming or causing operational delays. Any pipes exceeding 8 inches in diameter need to be split lengthwise to meet preparation standards.

Chemical composition limits typically restrict copper content to a maximum of 0.60%, with nickel limited to 0.45% and chromium to 0.20%. These residual alloy restrictions ensure the recycled steel meets quality specifications for new steel production. Materials with high alloy content, cast iron beyond minimal percentages, or hazardous substances face rejection or significant price penalties.

Processing considerations include the material’s ability to be handled efficiently by magnetic separation equipment and charging systems. The scrap must be prepared to ensure compact charging characteristics that optimize furnace space utilization. Proper preparation eliminates tangled materials, oversized pieces, and items that could impede automated handling systems.

Industry variations exist among different steel mills and regional markets, with some facilities maintaining stricter dimensional tolerances or density requirements. Electric arc furnace operations typically demand higher quality standards compared to other steel production methods. We work closely with mills to understand their specific requirements and ensure processed materials meet or exceed expectations.

How Does #1 Prepared Steel Differ from Other Scrap Grades?

Understanding the distinctions between steel grades is crucial for accurate materials assessment and optimal pricing in ferrous scrap operations. #1 prepared steel represents the premium category in ferrous recycling, defined by specific dimensional and thickness requirements that separate it from lower-grade classifications.

#1 prepared steel must meet strict criteria for both size and gauge thickness. The material cannot exceed 5 feet in length by 18 inches in width, with a minimum thickness of 1/4 inch or more. These specifications ensure it can be efficiently processed through standard shredding and melting equipment without additional preparation steps.

The dimensional constraints exist because smaller, uniformly-sized pieces integrate more easily into steel mill feed systems. This preparation reduces processing time and energy consumption, making #1 prepared steel more valuable in the secondary materials market.

Key Differences in Size and Thickness Requirements

#2 prepared steel operates under more restrictive dimensional parameters than #1 prepared steel. This grade requires materials to be less than 3 feet by 18 inches, with a thinner minimum gauge of 1/8 inch or more. The reduced thickness threshold means #2 prepared steel includes lighter-gauge materials that still maintain structural integrity.

The size reduction for #2 prepared steel reflects the material’s lower density and processing characteristics. Thinner materials require different handling and may need specialized sorting to prevent contamination with light iron during processing.

Both prepared grades exclude materials needing additional cutting, cleaning, or dimensional reduction. This preparation requirement distinguishes them from unprepared categories that arrive at facilities in their original, unprocessed state.

Unprepared Steel Characteristics

Unprepared steel encompasses materials exceeding the dimensional limits of prepared grades while maintaining substantial thickness. These pieces typically measure over 5 feet in length or 3 feet in width, depending on the facility’s classification system. Farm equipment, industrial machinery components, and structural elements often fall into this category.

The thickness requirement for unprepared steel matches #2 prepared at a 1/8 inch minimum, but oversized dimensions necessitate additional processing before recycling. This requirement directly impacts pricing, as facilities must allocate resources for cutting, sorting, and preparation.

Common examples include agricultural implements, construction equipment parts, large structural beams, and industrial piping systems. These materials contain valuable ferrous content but require significant labor investment for efficient processing.

Mixed and Sheet Steel Classifications

Mixed steel, also known as sheet steel or light iron, represents the most contaminated category in ferrous recycling. This classification includes thin-gauge materials with small non-metallic contaminants like plastic components, rubber attachments, or adhesive residues.

The contamination tolerance in mixed steel grades reflects the reality of consumer and industrial waste. Appliances, automotive body panels, and manufactured goods often contain mixed materials that cannot be completely separated during collection.

Light iron materials typically need specialized processing techniques, such as magnetic separation and shredding, to handle contaminated feed stocks. Non-ferrous contaminants reduce the overall value but do not eliminate the recycling potential of these materials.

Processing facilities often refer to mixed steel materials as “shreddables” because they’re commonly processed through automobile shredders that can handle mixed material compositions. This method separates ferrous content from contaminants while producing a marketable steel product.

The grade distinctions directly impact pricing structures across ferrous scrap markets. #1 prepared steel commands premium pricing due to its processing efficiency and consistent quality. Each grade reduction typically results in lower per-ton pricing, reflecting the additional processing requirements and reduced material density.

What is the General Process for Recycling Prepared Steel?

Recycling steel involves a systematic process that turns discarded materials into valuable resources for new manufacturing applications. This process includes five key stages that ensure maximum material recovery while maintaining quality. Understanding this workflow helps facilities optimize operations and achieve better sustainability outcomes.

Collection and Transportation

The recycling process starts with collecting prepared steel from various industrial and commercial sources. Collection points include construction sites, demolition projects, manufacturing facilities, and scrap yards that act as central gathering hubs. Transportation logistics are crucial for maintaining cost-effectiveness and ensuring materials efficiently reach processing facilities.

Specialized containers and vehicles handle different volumes of scrap steel, from small collections to large industrial shipments. Many recycling facilities coordinate pickup schedules to streamline the process and reduce transportation costs. Proper preparation at the source, including initial sorting and contaminant removal, significantly improves the efficiency of later processing stages.

Sorting and Magnetic Separation

Upon arrival at recycling facilities, comprehensive sorting separates ferrous materials from other metals and contaminants. Magnetic separation technology is the primary method for isolating steel and iron. Powerful electromagnets and magnetic drums effectively extract ferrous materials, allowing non-magnetic substances to pass through separately.

Visual inspection and advanced sorting equipment work alongside magnetic separation to ensure material purity. Spectrometers and other identification tools assist workers in categorizing different steel grades and removing non-metallic contaminants. This thorough sorting process directly affects the quality and value of the final recycled product.

Processing and Preparation

Steel processing involves mechanical reduction to optimize melting efficiency and material handling. Shredding equipment breaks down large steel objects into manageable pieces, typically ranging from fist-sized chunks to smaller fragments. Industrial shears and cutting tools handle structural steel components that require more precise sizing.

The processing stage also includes additional cleaning to remove paint, coatings, and attached non-metallic materials. Baling operations compress lighter steel materials into dense packages, facilitating easier transportation and improving furnace charging efficiency. Proper sizing ensures uniform heating during the melting process and reduces energy consumption.

Melting and Purification

Electric arc furnaces handle most steel scrap melting operations, using electrical energy to reach temperatures exceeding 3000°F. The intense heat transforms solid steel scrap into molten metal, burning off organic contaminants and oxidizing unwanted elements. Basic oxygen furnaces are an alternative method, particularly for larger-scale operations.

Purification occurs simultaneously with melting as impurities rise to form slag that can be removed. Refining processes introduce specific additives and alloys to adjust the chemical composition of the molten steel. This ensures the recycled material meets quality specifications for its intended applications and industry standards.

Solidification and Manufacturing Readiness

The final stage involves cooling and shaping molten metal into standardized forms for industrial use. Casting operations pour the purified steel into molds to create bars, sheets, billets, or coils, depending on market demand. Controlled cooling prevents structural defects and ensures consistent material properties throughout the solidified steel.

Quality control testing verifies that the recycled steel meets specifications before shipping to manufacturers. The solidified products are then ready for distribution to steel mills, fabricators, and manufacturers for transformation into new products. This completes the circular economy cycle, turning waste materials into valuable manufacturing inputs.

Why Is Recycling Prepared Steel Important?

Environmental Impact and Resource Conservation

Steel recycling provides notable environmental benefits that go beyond simply reducing waste. Recycling one ton of steel saves 642 kWh of energy, enough to power an average home for nearly two weeks. It also conserves 1.8 barrels of oil and prevents 4 cubic yards of material from reaching landfills.

The impact on resource conservation is equally significant. According to the Steel Recycling Institute, recycling one ton of steel saves about 2,500 pounds of iron ore, 1,400 pounds of coal, and 120 pounds of limestone. These savings lessen the environmental impact of mining, which can harm natural habitats and pollute waterways.

Steel recycling greatly reduces CO2 emissions compared to primary steel production. The process decreases greenhouse gas emissions by up to 85% and cuts air pollution by up to 86%, aiding in the fight against climate change and improving air quality in areas near steel production facilities.

Energy Efficiency and Circular Economy Benefits

The energy savings from steel recycling have a positive impact across the manufacturing sector. Steel maintains its properties through endless recycling cycles, making it integral to circular economy principles. Unlike other materials that degrade with each recycling, steel retains its strength and durability indefinitely.

Producing steel from recycled scrap requires much less energy than using virgin materials. This energy efficiency reduces the demand on power grids and lowers overall industrial energy consumption. The yearly energy savings from steel recycling are sufficient to power 20 million homes for an entire year.

Economic Benefits and Supply Chain Stability

Steel recycling offers significant economic opportunities across various sectors. It creates jobs in collection, sorting, processing, and transportation, supporting hundreds of thousands of workers nationwide. Iron and steel scrap have contributed approximately $23 billion in domestic sales and exports in recent years.

Incorporating recycled steel into operations enhances supply chain resilience for businesses. It reduces reliance on newly mined raw materials, which can be subject to price fluctuations due to extraction challenges or geopolitical factors. This stability helps manufacturers keep production costs and delivery schedules consistent.

The economic benefits also extend to sellers of scrap steel. Metal recycling facilities consistently purchase steel scrap due to its steady demand from manufacturers, providing a reliable income source for businesses disposing of steel equipment, construction materials, or outdated infrastructure while also supporting local recycling economies.

Conclusion: Maximizing Value with Proper Steel Preparation

Understanding the criteria for #1 prepared steel is essential for maximizing its value and contributing to a sustainable recycling ecosystem. By ensuring scrap steel meets the required dimensions, thickness, and is free of contaminants, sellers can secure better prices. This careful preparation supports a more efficient recycling process, conserves natural resources, and strengthens the circular economy. Proper steel preparation shows how strategic scrap management can increase profitability and reduce environmental impact through resource efficiency.

Whether managing construction debris, industrial waste, or facility upgrades, proper scrap metal classification significantly impacts returns and sustainability outcomes. Contact Okon Recycling at 214-717-4083 for guidance on maximizing your steel scrap value while practicing responsible recycling.