5901 Botham Jean Blvd, Dallas, TX 75215

Ferrous Metal Recycling: A Guide to Environmental & Economic Benefits

November 8, 2025Steel ranks as the most recycled material worldwide. This demonstrates the significant impact of ferrous metal recycling on global waste management. Almost 98% of structural steel is recovered and processed for reuse, highlighting ferrous recycling as a leading example of sustainable resource management.

Ferrous metal recycling involves reprocessing discarded metals mainly composed of iron and steel. These metals are easily identified by their magnetic properties and tendency to rust. A simple magnet test can quickly determine if a metal contains iron—if the magnet sticks, it can be recycled.

Common sources include old vehicles, construction materials like steel beams, industrial equipment, and household appliances. Items such as refrigerators, washing machines, car frames, and even railroad tracks all contain ferrous metals. This practice is crucial in global recycling efforts, promoting resource sustainability by diverting materials from landfills and supporting the circular economy.

Why Is Recycling Ferrous Scrap Metal So Important?

Recycling ferrous scrap metal is one of the most effective sustainability practices in modern waste management. Steel is the most recycled material in the world, with nearly 98% of structural steel being recovered and processed for reuse. This high recycling rate highlights the essential role ferrous materials play in fostering a circular economy where resources retain their value through multiple lifecycles.

The environmental benefits of recycling ferrous scrap metal go far beyond waste reduction. Each ton of recycled steel conserves approximately 2,500 pounds of virgin ore, 1,400 pounds of coal, and 120 pounds of limestone. These natural resources are finite and require intensive mining operations that often lead to habitat destruction, soil erosion, and water contamination. By using existing ferrous materials, we considerably reduce the environmental impact of metal production.

Energy consumption is another major advantage of recycling ferrous scrap. The process uses up to 74% less energy compared to producing steel from virgin materials. This significant reduction leads directly to lower greenhouse gas emissions, with recycled steel production cutting CO2 emissions by 58% compared to traditional methods. Manufacturing businesses can achieve energy cost savings exceeding 50% by incorporating recycled ferrous materials into their operations.

Economic benefits ripple through various sectors when ferrous scrap recycling programs are effectively implemented. In 2017, the United States processed 66 million metric tons of ferrous scrap valued at $15.9 billion, showcasing their substantial market value. The recycling industry supports thousands of jobs across collection, processing, and manufacturing. Businesses benefit financially from scrap recycling through reduced waste disposal costs and revenue generation from selling valuable materials.

Recycled ferrous materials have industrial applications across virtually every sector. Construction projects utilize recycled steel for beams and reinforcement materials. Automotive manufacturers use recycled metals in vehicle production, maintaining performance standards while reducing costs. Infrastructure development relies heavily on recycled steel for bridges, rail systems, and utility structures, ensuring consistent demand across diverse industries.

Landfill waste prevention is another critical benefit of ferrous scrap recycling. Steel decomposes very slowly in landfills, occupying valuable space for hundreds of years. Some ferrous materials contain hazardous substances that can leach into soil and groundwater over time. Diverting these materials from landfills prevents long-term environmental contamination and preserves landfill capacity for materials that cannot be effectively recycled.

What Are The Common Applications For Recycled Ferrous Metals?

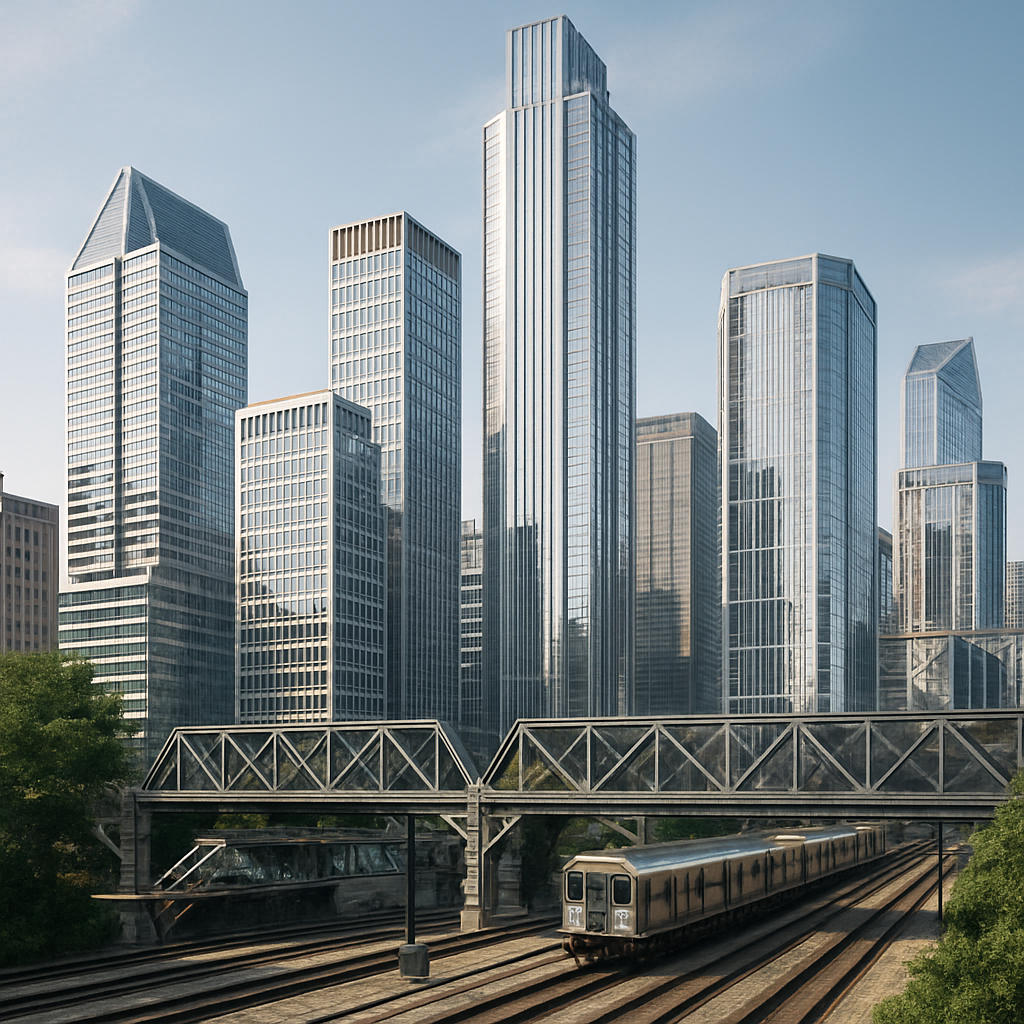

The construction sector is the largest consumer of recycled ferrous metals, incorporating these materials into essential structural components. Steel beams form the backbone of commercial buildings and skyscrapers, providing the necessary load-bearing capacity for multi-story structures. Reinforcing bars, or rebar, strengthen concrete foundations and structural elements in both residential and commercial projects. Construction companies also use recycled steel for columns, trusses, and prefabricated components, reducing on-site assembly time.

Roofing applications represent another important use for recycled ferrous metals in construction. Steel roofing systems offer durability and weather resistance while supporting sustainable building practices. The mechanical and electrical systems within buildings utilize recycled steel for pipes, conduits, and HVAC components, ensuring long-term functionality and efficiency.

The automotive sector extensively uses recycled steel to manufacture new vehicles, meeting both performance standards and sustainability goals. Car bodies, chassis components, and engine parts are often made from recycled ferrous metals. Vehicle manufacturers integrate recycled steel into fenders, doors, and structural frames, maintaining safety requirements while reducing environmental impact. The automotive industry’s commitment to recycling helps create a circular economy where end-of-life vehicles become raw materials for new production.

Electric vehicle production increasingly relies on recycled ferrous metals for battery housing, structural components, and wiring systems. This supports the industry’s transition toward cleaner transportation while maximizing resource efficiency.

Infrastructure development projects consume substantial quantities of recycled ferrous metals for bridges, tunnels, and railway systems. Bridge construction uses recycled steel for girders, support structures, and reinforcement elements that must withstand heavy loads and environmental stresses. Railway infrastructure incorporates recycled steel in track components, signal systems, and station facilities.

Transportation networks benefit from recycled ferrous metals in guardrails, signage supports, and maintenance structures. These applications show how recycled materials support critical infrastructure while reducing the demand for virgin steel production.

Industrial machinery manufacturing is a growing area for recycled ferrous metals. Production equipment, heavy machinery, and specialized tools incorporate recycled steel components that meet demanding operational requirements. Manufacturing facilities use recycled ferrous metals for conveyor systems, processing equipment, and structural supports within production environments.

White goods manufacturing, including refrigerators, washing machines, and dishwashers, relies on recycled steel for both structural and aesthetic components. Appliance manufacturers use recycled ferrous metals for outer casings, internal frameworks, and mechanical elements. This sector demonstrates how recycled materials maintain quality standards while supporting household appliance production.

The versatility of recycled ferrous metals extends to modular construction systems, where prefabricated building elements are manufactured off-site for efficient installation. These systems use recycled steel for standardized components that reduce construction time and material waste. Modular construction applications include temporary structures, residential housing, and commercial facilities that prioritize sustainability and efficiency.

What are the Primary Challenges In Ferrous Metal Recycling?

Contamination is a significant obstacle in ferrous metal recycling. Paints, coatings, and non-metallic materials often attach to scrap iron and steel, making separation during processing difficult. These contaminants can burn during melting, releasing harmful emissions and leaving residues that compromise the quality of recycled products.

The contamination issue goes beyond surface materials, encompassing hazardous substances and chemical treatments used throughout the metals’ lifecycle. These contaminants increase processing costs and require additional treatment steps. Advanced sorting technologies and rigorous quality control have become essential investments for maintaining the material purity that end markets demand.

Collection logistics present another complex challenge affecting the entire ferrous metal recycling supply chain. Establishing a consistent scrap supply relies on effective collection systems, transportation networks, and public participation in recycling programs. The geographic distribution of scrap sources often leads to inefficiencies, especially when collection points are far from processing facilities.

Storage and handling logistics add to these difficulties. Ferrous metals require proper storage to prevent further oxidation and contamination from environmental exposure. Weather conditions, moisture, and inadequate storage facilities can degrade material quality, reducing the value of collected scrap. Efficient logistics planning is crucial for maintaining economic viability and ensuring a steady material flow to processing operations.

Market fluctuations create significant economic challenges that directly impact recycling profitability. Global metal prices can experience dramatic swings due to international trade policies, economic conditions, and industrial demand patterns. These price movements affect both the revenue recyclers receive for processed materials and the costs they can offer scrap suppliers.

Economic downturns pose particular challenges when manufacturing demand decreases and scrap prices fall. During these times, collection activities may become unprofitable, creating supply shortages even as markets recover. This volatility requires recycling facilities to develop flexible business strategies and maintain financial reserves to weather downturns and be ready for recovery phases.

Regulatory compliance adds complexity to ferrous metal recycling operations. Environmental regulations require investments in pollution control equipment, monitoring systems, and administrative processes, increasing operational costs. Water quality management, air emission controls, and waste disposal protocols all contribute to the expense structure that recyclers must balance against market prices.

Public awareness is a fundamental challenge affecting collection efficiency and material quality. Many potential scrap contributors are unaware of proper separation techniques or the economic value of ferrous materials. Education initiatives and outreach programs require ongoing investment, yet they are essential for building the participation levels needed to support sustainable recycling operations.

Conclusion: The Lasting Impact of Ferrous Metal Recycling

Ferrous metal recycling is a transformative approach to waste management that delivers measurable environmental and economic benefits. It reduces energy consumption by 60 percent compared to virgin steel production while cutting CO2 emissions by 58 percent. These statistics highlight how effective resource management through recycling can have a lasting impact across industries. The circular economy advantages go beyond environmental gains, generating billions in economic activity and supporting hundreds of thousands of jobs in collection, processing, and manufacturing sectors.

Achieving a sustainable future requires collaboration between municipalities, manufacturers, and recycling providers to maximize industrial innovation. The infinite recyclability of ferrous metals makes this partnership essential for long-term resource security. Organizations aiming to implement comprehensive ferrous metal recycling programs that promote environmental stewardship and operational efficiency can contact Okon Recycling at 214-717-4083.