5901 Botham Jean Blvd, Dallas, TX 75215

What Is the Process for Handling Pyrophoric Materials Like Magnesium?

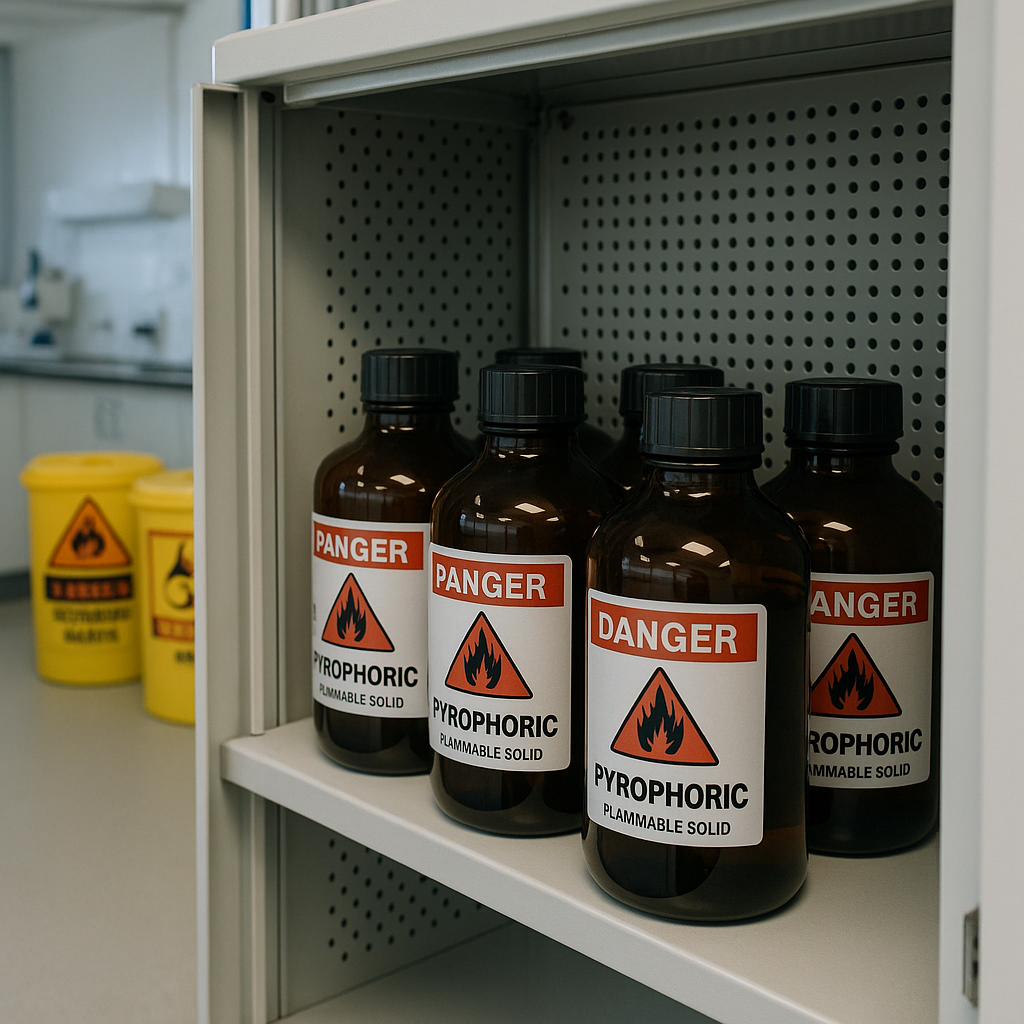

November 6, 2025The term “pyrophoric” originates from the Greek words “pyro” (fire) and “phoros” (bearing). These substances earn their name by igniting spontaneously when exposed to air. Magnesium, in its finely divided form, is one of the most common pyrophoric materials found in research laboratories and industrial facilities.

Pyrophoric materials such as magnesium can ignite within seconds of air exposure without any external ignition. This spontaneous combustion is due to their high reactivity with oxygen or moisture in the air. The resulting fires or explosions pose serious risks to laboratory personnel and operations. Water-reactive chemicals can exacerbate these hazards by producing flammable gases and significant heat.

What Are The Primary Hazards Associated With Pyrophoric Materials?

Pyrophoric materials pose immediate fire risks due to their high reactivity with oxygen. These substances ignite spontaneously when exposed to air, often within minutes or even seconds of contact. The rapid combustion creates intense heat that can quickly spread to surrounding materials in waste processing facilities.

The most critical safety concerns include:

- Spontaneous combustion upon oxygen exposure

- Explosive reactions with water or moisture

- Severe thermal burns from direct contact

- Toxic fume generation during combustion

- Chemical corrosivity causing tissue damage

Thermal runaway is particularly dangerous in recycling operations. When pyrophoric materials undergo exothermic reactions, the heat generated can trigger additional reactions that spiral out of control. This cascade can compromise entire processing areas and endanger personnel handling mixed waste streams.

Water-reactive pyrophoric substances create additional complications during waste management. These materials generate hydrogen gas when exposed to moisture, creating explosive atmospheres that pose serious risks to facility safety. The combination of flammable hydrogen production and spontaneous ignition potential makes proper identification and segregation critical.

Direct contact hazards extend beyond immediate burns. Many pyrophoric compounds cause severe chemical burns that penetrate deep into tissue. Workers face exposure risks through skin contact, eye splash, or accidental inhalation of reactive vapors during sorting and processing operations.

Long-term health effects compound immediate safety concerns. Certain pyrophoric materials target specific organ systems, potentially causing damage to the liver, kidneys, and central nervous system. According to Lab Manager, exposure to these substances can also lead to teratogenic effects and organic peroxide formation, creating lasting health complications for exposed individuals.

Fume inhalation presents ongoing risks throughout handling procedures. Toxic vapors released during pyrophoric reactions can cause immediate respiratory distress and longer-term pulmonary damage. Proper ventilation systems are essential for protecting workers from these airborne hazards during waste processing activities.

What Safety Equipment and Environment Are Necessary for Handling?

Proper safety equipment and controlled environments are crucial for safely handling pyrophoric materials in waste management operations. These materials require more rigorous protection protocols than standard chemical safety measures.

Essential Personal Protective Equipment

Eye and face protection are the first line of defense when handling pyrophoric materials. Chemical splash goggles meeting ANSI Z-87.1 standards are essential for protection against splashes and debris, whereas standard prescription glasses offer insufficient protection unless they conform to this safety standard.

Face shields are mandatory when explosion risks exist or highly exothermic reactions may occur. These should be used in conjunction with safety goggles, rather than as replacements, to ensure comprehensive protection for laboratory personnel working with volatile pyrophoric waste streams.

Fire-resistant lab coats made from materials such as Nomex fabrics offer superior protection over synthetic alternatives. Cotton or wool clothing underneath these coats helps prevent severe thermal burns that could be caused by synthetic materials like polyester or nylon. The lab coat must be fully buttoned and properly fitted to maximize skin coverage.

Hand protection depends on the specific pyrophoric materials being processed. Nitrile gloves provide adequate protection for small quantities in research-scale operations, while double-layered nitrile gloves offer extra protection for routine handling. For larger quantities of pyrophoric waste, heavier chemical-resistant gloves or flame-resistant options are necessary. The material safety data sheet for each chemical guides appropriate glove selection, with proper fit ensuring dexterity while maintaining protection.

Required Environmental Controls

Fume hood operation requires specific protocols when processing pyrophoric materials. The sash should remain at the lowest possible height while allowing necessary operations, maximizing containment and providing adequate worker protection.

All unnecessary equipment and combustible materials must be cleared from the fume hood before starting work, as items like paper towels and cleaning wipes pose fire hazards in the presence of pyrophoric materials. Only essential tools and equipment should remain in the work area.

Glove boxes provide excellent environmental control when inert atmosphere conditions are required. These enclosed systems maintain nitrogen or argon atmospheres to prevent unwanted reactions with oxygen or moisture. Personnel should receive specific training on glove box operation procedures before handling pyrophoric materials in these environments.

Inert atmosphere maintenance requires continuous monitoring and appropriate gas flow rates. Exit bubblers and pressure relief systems prevent dangerous pressure buildups while maintaining protective conditions. Regular atmosphere testing ensures oxygen levels remain below critical thresholds.

Emergency Safety Equipment

Emergency eyewash stations must be accessible within ten seconds of travel time from pyrophoric material handling areas. These stations require regular testing to ensure proper water flow and clarity. Personnel should be familiar with locations and activation procedures before starting work.

Safety showers provide essential emergency response capability for personnel contamination or clothing fires. Delivering twenty gallons per minute of cool water, these installations aid in effective decontamination. Regular inspection and maintenance ensure their reliability during emergencies.

Fire extinguishing equipment selection depends on the specific pyrophoric materials being handled. ABC dry powder extinguishers are effective for most organolithium and alkylmetal reagents, while Class D extinguishers are necessary for pyrophoric metals like sodium, potassium, or lithium aluminum hydride.

Specialized spill response materials should be readily available near pyrophoric work areas. Dry sand, sodium carbonate, calcium oxide, and clay-based absorbents can smother small spills and prevent ignition. These materials should be stored in easily accessible containers within the immediate work zone.

Workspace Configuration

Secondary containment systems prevent spilled materials from spreading beyond the immediate work area. Glass crystallizing dishes or metal pans effectively contain spills from bottles and transfer operations, catching minor spills before they reach other materials or surfaces.

Ventilation systems need careful evaluation to ensure adequate air exchange without creating hazardous conditions. Excessive air flow can disrupt inert atmosphere maintenance, while insufficient ventilation allows dangerous vapor accumulation. Balance these requirements based on specific operational needs.

Work scheduling should avoid periods of isolation when fewer personnel are available for emergency assistance. Pyrophoric material handling requires at least two qualified individuals present during all operations, following a buddy system approach to ensure help is available promptly during emergencies or unexpected reactions.

What Are The Universal Best Practices For Handling These Materials?

Effective pyrophoric material handling requires systematic preparation and strict adherence to safety protocols. These materials demand specialized techniques that differ significantly from standard waste processing procedures. The following best practices have been developed through decades of laboratory research and real-world applications in materials recovery operations.

Training and Preparation Requirements

**Never work alone** when handling pyrophoric materials. The buddy system provides essential safety oversight and immediate emergency response capabilities. A supervisor or experienced colleague must observe proper techniques before any worker handles these materials independently.

Conduct dry runs using non-hazardous materials to practice procedures. Rehearsing helps workers develop muscle memory for critical steps without exposure risks. Training must include emergency response procedures, proper equipment use, and hazard recognition skills.

All personnel require comprehensive education on material safety data sheets and specific hazard properties. Workers should understand the reactivity patterns, storage requirements, and compatibility issues before beginning any handling operations.

Essential Workspace Preparation

Remove all flammable materials from the immediate work area. Pyrophoric substances ignite instantly upon air exposure, making fire prevention the primary concern. Clear workspaces reduce the severity of potential incidents and improve emergency response effectiveness.

Secure pyrophoric reagent bottles to prevent accidental tipping or displacement. Use clamps or stands designed for chemical containers rather than attempting to control bottles manually during transfers. This approach maintains stability while keeping hands free for precise handling operations.

Ensure all glassware undergoes oven-drying and remains moisture-free before use. The water-reactive properties of many pyrophoric materials create additional hazards when combined with residual moisture. Store dried equipment in desiccators or under an inert atmosphere until needed.

Transfer Techniques and Volume Guidelines

Use syringes for transferring volumes under 20 mL of pyrophoric liquids. Larger syringes create higher pressure risks and increase the consequences of mechanical failure. Select luer-lock syringes with a capacity at least 25% greater than the intended transfer volume.

Apply the cannula technique (double-tipped needle) for volumes exceeding 20 mL. This method enables hands-free operation and reduces direct handling risks associated with larger quantities. The cannula system maintains inert atmosphere protection throughout the transfer process.

Maintain inert atmosphere conditions during all transfer operations. Use nitrogen or argon gas systems with proper pressure regulation and bubbler protection. Never attempt transfers in ambient air conditions, as even brief exposure can trigger ignition.

Personal Protective Equipment Standards

Wear fire-resistant laboratory coats made from natural fibers or specialized materials like Nomex. Synthetic clothing materials can melt against the skin during fire exposure, causing severe thermal injuries. Natural fiber clothing chars rather than melting, providing better protection.

Use chemical splash goggles and face shields for eye protection. Standard prescription glasses provide insufficient coverage against splashing or ignition events. Double-layer glove systems combining nitrile and fire-resistant materials offer optimal hand protection.

Avoid loose clothing or synthetic fabrics that could ignite easily. Tie back long hair and remove jewelry that might interfere with emergency procedures or catch fire during incidents.

Emergency Preparedness Measures

Position appropriate fire suppression materials within immediate reach. Dry powder ABC fire extinguishers work effectively against most pyrophoric materials, while Class D extinguishers handle combustible metal fires. Avoid water-based or CO2 systems that may worsen pyrophoric fires.

Keep spill control materials, including dry sand, powdered lime, or clay-based absorbents, readily available. These materials smother small fires and contain spills before they spread. Safety showers and eyewash stations must be accessible within ten seconds of the work area.

Establish clear evacuation procedures and emergency contact protocols. Workers should know alarm locations, evacuation routes, and proper notification procedures for different incident types. Regular emergency drills reinforce these critical response patterns.

How Should Pyrophoric Materials Be Stored and Disposed Of Correctly?

Storage Requirements

Proper storage of pyrophoric materials requires strict adherence to inert atmosphere protocols. Store these materials under nitrogen or argon gas to prevent contact with atmospheric oxygen and moisture. Some pyrophoric solids, like sodium and lithium, come as dispersions in mineral oil or kerosene, which reduces their reactivity and provides safer storage conditions.

All storage containers must carry clear chemical names and hazard warnings. Keep pyrophoric materials in secondary containment systems, using only compatible materials within the same storage area. The original manufacturer’s sealed containers often provide the best storage solution when properly maintained under inert gas pressure.

Storage locations should be segregated from heat sources, flames, oxidizers, and water. Minimize the quantities stored in laboratory settings and conduct regular inspections of container integrity. Temperature-controlled environments help maintain chemical stability, while proper ventilation systems manage any potential vapor releases.

Disposal Protocols

Disposing of pyrophoric materials requires careful neutralization procedures before final waste processing. Never open containers with residual pyrophoric materials directly to the atmosphere. Instead, transfer unused reagents to reaction flasks under inert gas flow, maintaining positive pressure throughout the process.

The neutralization process begins with cooling the reaction vessel using dry ice and acetone baths. Slowly add isopropyl alcohol while maintaining temperature control, followed by methanol for complete hydrolysis. This step-by-step approach prevents violent reactions that could cause fires or injuries.

All contaminated equipment, including glassware, syringes, needles, and protective equipment, must be treated as hazardous waste. Conduct solvent rinses under inert atmosphere conditions, collecting all rinsates for proper disposal. The Stanford Environmental Health and Safety guidelines emphasize that bulk materials in original containers should not be quenched prior to disposal but instead tagged for professional hazardous waste collection.

Chemical waste streams from pyrophoric material processing require special handling protocols. Document all waste components on hazardous waste labels and coordinate with environmental protection teams for pickup scheduling. Proper disposal prevents contamination of standard recycling streams and protects waste management personnel from exposure risks.

Conclusion: Mastering Safety in Pyrophoric Material Handling

Handling pyrophoric materials safely requires strict protocols, proper personal protective equipment, and designated work areas that focus on both worker safety and environmental protection. These reactive substances necessitate specialized disposal procedures, generating hazardous waste streams that must be managed through certified processes. By implementing comprehensive safety measures, maintaining emergency preparedness protocols, and fostering a culture of safety awareness, laboratories can use these valuable chemicals effectively while minimizing fire and explosion risks.

The proper management of pyrophoric materials and contaminated equipment is crucial for laboratory safety and regulatory compliance. For expert guidance on safely disposing of pyrophoric waste or implementing sustainable waste management practices, contact Okon Recycling at 214-717-4083 for specialized recycling solutions that ensure both safety and environmental responsibility.