5901 Botham Jean Blvd, Dallas, TX 75215

Understanding De-Tinning and Why is it Necessary

October 23, 2025In metal recycling, not all processes are as straightforward as simply melting materials for reuse. Take the humble food can in your recycling bin – beneath its seemingly simple exterior lies a complex recycling challenge, which is where de-tinning comes into play.

De-tinning is the specialized process of removing the thin layer of tin coating that covers steel cans before proper recycling. While this coating serves as crucial protection against rust and corrosion during a can’s life, it presents problems when the can reaches the end of its lifecycle. Without proper tin removal, recycled steel becomes contaminated with tin, leading to significant quality issues.

The necessity of de-tinning becomes clear when examining its impact on steel quality. When tin-contaminated steel is processed, it can develop conditions known as surface hot shortness and temper embrittlement. This means the recycled steel becomes brittle and prone to cracking during manufacturing. Tin tends to concentrate at the grain boundaries within the steel, reducing cohesion between grains and increasing the likelihood of fractures—a serious issue for any steel product.

What are the Main Methods for De-Tinning Steel Cans?

The de-tinning processes are categorized into two main types: pyrometallurgical and hydrometallurgical methods, each with distinct benefits and challenges for recovering valuable tin from steel can waste.

Pyrometallurgical Methods

Pyrometallurgical processes utilize heat to separate tin from steel by exploiting the molecular properties of metals at high temperatures.

The calcium reaction process involves treating steel melts with calcium-containing compounds, such as CaC2 or CaF2, at temperatures between 1550-1650°C. The calcium binds with tin impurities. While this method can effectively remove tin, it may cause unwanted re-carburization of the steel.

Vacuum distillation uses the different vapor pressures of iron and tin under controlled vacuum conditions at very low pressures (10-100 Pa). Tin evaporates more readily than iron, enabling separation. This technique produces no harmful byproducts but requires complex equipment.

Other pyrometallurgical approaches include sulfidation, where scraps are heated with reactive gases to form a removable brittle layer, and chlorination, which creates volatile SnCl4 but requires careful handling of chlorine gas.

Hydrometallurgical Methods

Hydrometallurgical processes use aqueous solutions to dissolve and recover tin, typically more cost-effective than pyrometallurgical approaches.

Alkaline leaching involves immersing tinplate scraps in hot alkaline solutions, typically sodium or potassium hydroxide. The tin dissolves into the solution as sodium stannate (Na2SnO3). Oxidizing agents are often added to expedite dissolution. This method can achieve tin levels below 0.028% with adequate processing time.

Electrolytic de-tinning is the most widely used industrial method. It uses an electrochemical cell where tin-coated steel serves as the anode. When current flows through a sodium hydroxide solution, tin dissolves from the anode and deposits on the cathode as a recoverable spongy material. This approach effectively removes tin to levels below 0.02%.

Comparing De-Tinning Methods

- Pyrometallurgical methods accommodate various forms of scrap but require significant energy input and complex equipment.

- Hydrometallurgical methods are generally more economical and use simpler equipment.

- Electrolytic processes achieve higher de-tinning efficiency (90-97%) compared to most other methods.

- Alkaline leaching is effective on surface coatings but requires longer processing times.

- Vacuum distillation has no chemical waste but incurs higher operating costs and longer processing times.

The steel recycling industry generally favors hydrometallurgical approaches, particularly electrolytic de-tinning, due to their effectiveness, cost efficiency, and minimal environmental impact for processing tin-plated steel waste.

| Method | Advantages | Disadvantages |

| Pyrometallurgical | – Can handle various forms of scrap – Produces no harmful byproducts in processes like vacuum distillation – Effective tin removal: Vacuum distillation efficiently separates due to vapor pressure differences |

– Requires significant energy input – Complex equipment needed – May lead to unwanted re-carburization – Lower lithium recovery – High energy intensity and emissions (fossil fuel consumption) |

| Hydrometallurgical | – More economical – Uses simpler equipment – Achieves high tin removal efficiency (e.g., 90-97% through electrolytic de-tinning) – Effective on surface coatings: Alkaline leaching is effective but slower – Environmentally friendly with zero discharge – Lower energy and emissions – High purity product recovery with superior selectivity |

– Generally longer processing times – Electrolytic processes require careful handling for high efficiency – High capital intensity, requiring significant upfront investment, especially for large volumes |

How Does the Electrolytic De-Tinning Process Work?

Electrolytic de-tinning is a sophisticated recycling method that selectively removes tin from steel without damaging the underlying substrate. This process uses basic electrochemical principles to efficiently separate these materials, preparing them for reuse in the circular economy.

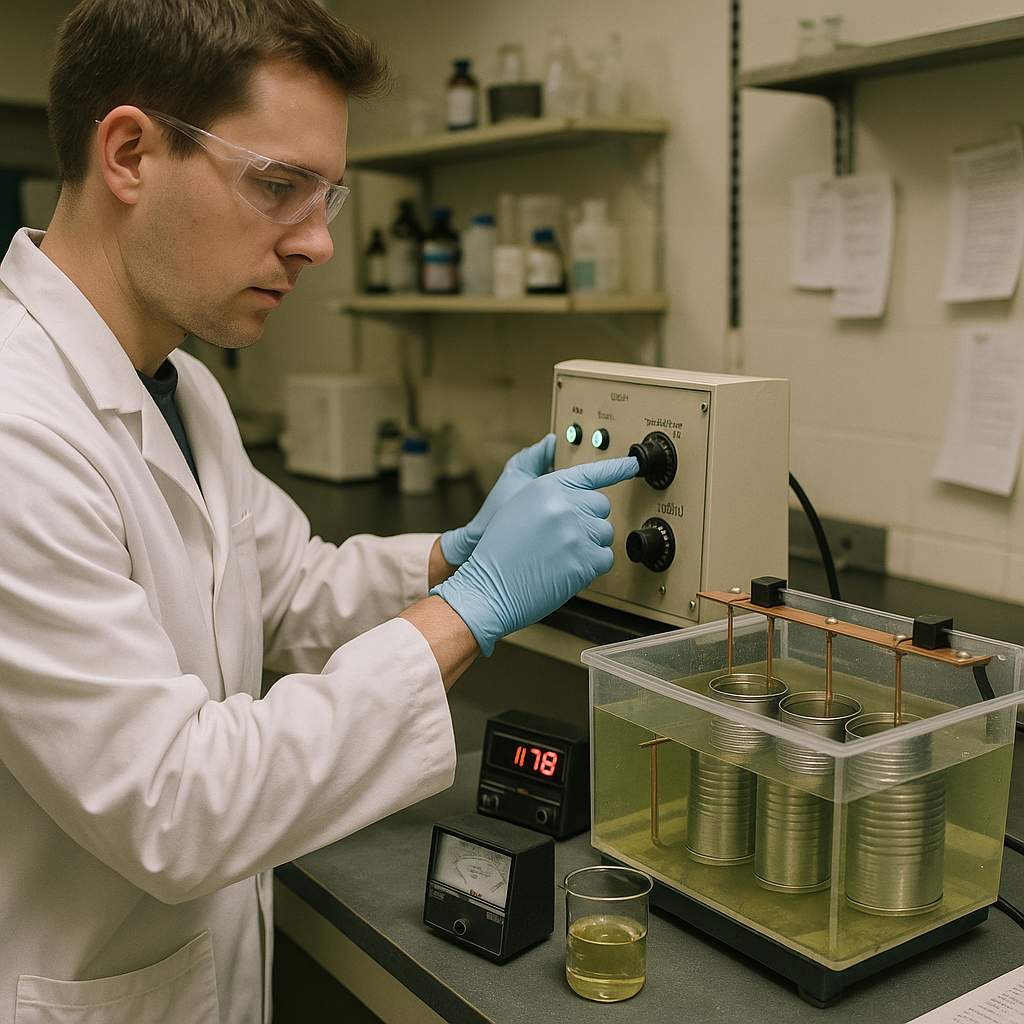

Electrochemical Cell Setup

The electrolytic de-tinning system comprises a basic electrochemical cell with key components. The tin-plated scrap functions as the anode (positive electrode), while a metal plate serves as the cathode (negative electrode). Both electrodes are immersed in a heated alkaline solution, typically sodium hydroxide (NaOH) at a concentration of about 2.5 molar.

The distance between electrodes is carefully controlled to optimize the current flow, and the solution is usually heated to temperatures between 70-80°C. This elevated temperature is crucial because it prevents anode passivation and enables the dissolution of both the pure tin coating and the tin-iron alloy layer beneath.

Chemical Reactions

When direct current is applied to this setup, several electrochemical reactions occur. At the anode, tin undergoes oxidation and dissolves into the solution primarily as stannite ions:

Sn + 3OH− → HSnO₂− + H₂O + 2e−

In the alkaline solution, these stannite ions can be further oxidized to stannate ions:

HSnO₂− + 3OH− + H₂O → Sn(OH)₆²− + 2e−

At the cathode, the dissolved tin ions are reduced back to metallic tin, forming a spongy deposit that can be easily collected:

Sn(OH)₆²− + 4e− → Sn + 6OH−

Process Parameters and Efficiency

The effectiveness of electrolytic de-tinning depends on several key parameters. The applied current density significantly impacts the process time and efficiency. Lower current densities generally yield better results but require longer processing times.

The optimal operating temperature is around 70°C, as this prevents the formation of passivating oxide layers on the anode surface. At room temperature, only the pure tin coating would dissolve, leaving behind the tin-iron alloy layer. Higher temperatures ensure complete removal of tin from the steel substrate.

The surface-to-volume ratio (S/V) of the scrap material also plays a crucial role in process efficiency. Materials with higher S/V ratios show better de-tinning results, as more surface area is exposed to the electrolyte. Properly shredded or crushed tin-plated scrap performs better in the de-tinning process.

Two-Stage Voltage Pattern

During the de-tinning process at optimal temperatures, the applied voltage follows a characteristic two-stage pattern. The first voltage increase occurs when the pure tin coating dissolves completely. The second voltage jump indicates the dissolution of the tin-iron alloy layer. When the voltage reaches its highest value, both tin layers have been removed, and the process is complete.

This voltage pattern serves as an essential indicator for process monitoring and control. It allows operators to determine the exact moment when the de-tinning process is complete, preventing unnecessary energy consumption and maximizing efficiency.

Industrial Applications and Benefits

In industrial settings, electrolytic de-tinning offers several advantages. It selectively removes tin without damaging the steel substrate, produces high-purity tin for recovery and reuse, and prepares the steel for conventional recycling processes. The tin recovered through this process typically has a purity of 95-97%, making it valuable for various applications.

Modern de-tinning facilities can process thousands of tons of tin-plated scrap annually, significantly reducing the need for virgin tin production and minimizing the environmental impact of waste disposal. This process exemplifies the principles of a circular economy by transforming waste materials into valuable resources.

What are the Key Factors Affecting Electrolytic De-Tinning Efficiency?

Electrolytic de-tinning efficiency depends on several interrelated factors that must be carefully controlled to achieve optimal results. Understanding these key parameters helps recycling facilities maximize tin removal while minimizing energy consumption and processing time.

Current density is one of the most influential factors in the de-tinning process. Research shows that lower current densities generally yield better results, though at the expense of longer processing times. At 70°C, tests indicate that current densities around 47.6 A/m² can achieve up to 99.5% tin removal efficiency, compared to 98.8% at 158.7 A/m².

Temperature

Temperature plays a crucial role in overcoming surface passivation during de-tinning. Processes at room temperature typically remove only the pure tin coating, leaving the tin-iron alloy layer intact. Operating at around 70°C is essential for:

- Preventing anode passivation that blocks tin dissolution

- Enabling dissolution of the tin-iron intermetallic layer

- Improving efficiency by allowing complete tin removal to levels below 0.01% by weight

At temperatures below 70°C, the formation of a Sn(OH)₂/SnO film at the anode hinders the dissolution, significantly reducing efficiency. Higher temperatures may further increase tin removal rates but require additional energy input.

Process Time

The optimal process time must balance complete tin removal with energy efficiency. The time needed for effective de-tinning follows a power-law relationship with current density, expressed as:

τ = 1824.8i⁻⁰·⁷²⁷ (at 70°C)

Where τ is the process time in seconds and i is the current density in A/m². The ideal process time corresponds to the point at which the applied voltage reaches its maximum value, indicating complete dissolution of both the tin coating and tin-iron alloy.

Surface-to-Volume Ratio

Perhaps the most significant factor for processing scrap is the surface-to-volume (S/V) ratio. Since electrolytic de-tinning is fundamentally a surface process, materials with higher S/V ratios yield dramatically improved results:

- Materials with S/V ratios of about 500 m⁻¹ can achieve around 94.4% tin removal

- Increasing the S/V ratio to 5000 m⁻¹ improves efficiency to 97.4% under identical conditions

- An S/V ratio of at least 581.8 m⁻¹ is needed for bar steel (tin < 0.06%)

- Cold-rolled sheet steel requires an S/V ratio of about 2165 m⁻¹ to meet stricter requirements (tin < 0.02%)

The relationship between residual tin content and S/V ratio follows the expression: Sn = 12.288(S/V)⁻⁰·⁸³⁶, where Sn is the residual tin in weight percent.

Electrolyte Composition

While sodium hydroxide concentration is typically kept at 2.5M (around 10% by weight), additives can further enhance process efficiency. Additives like Na₂SnO₃·3H₂O limit side reactions, while Na₂CO₃ counteracts the decrease in NaOH concentration during operation. However, excessive addition of these substances can decrease the critical current density of passivation and increase electrolyte resistance.

Understanding these factors allows recycling operations to optimize their processes for specific materials and quality requirements. By carefully balancing these parameters, facilities can achieve high tin removal rates while minimizing energy consumption and maximizing throughput.

| Parameter | Efficiency | Impact |

| Current Density | 99.5% at 47.6 A/m² | Higher densities reduce efficiency but shorten time |

| Temperature | Complete removal below 0.01% at 70°C | Enables dissolution of tin-iron layer |

| Process Time | τ = 1824.8i⁻⁰.⁷²⁷ (at 70°C) | Determined by voltage reaching maximum |

| S/V Ratio | 94.4% at 500 m⁻¹, 97.4% at 5000 m⁻¹ | Higher ratios improve efficiency |

Conclusion: Optimizing the De-Tinning Process for Steel Can Recycling

Electrolytic de-tinning is the most effective method for processing tin-coated steel cans. Research indicates that factors such as operating temperature, current density, and surface-to-volume ratio are crucial to its efficiency and economic viability. Specifically, maintaining temperatures above 70°C facilitates the dissolution of both the pure tin coating and the tin-iron intermetallic layer. While lower current densities ensure superior tin removal, they also extend processing time, necessitating a balance between throughput and quality.

The surface-to-volume (S/V) ratio is particularly significant. Steel can scrap with higher S/V ratios achieves better de-tinning efficiency with reduced energy consumption and shorter processing times, underscoring the importance of proper scrap preparation through effective shredding and handling. To optimize results, it’s essential to maximize the exposed surface area of the scrap. For your recycling needs and to learn more about optimizing metal recycling processes, contact Okon Recycling at 214-717-4083.