5901 Botham Jean Blvd, Dallas, TX 75215

Railway Scrap Metal Recycling: Process, Materials, & Benefits

October 26, 2025Railway scrap metal recycling involves the systematic recovery and reprocessing of valuable metals from decommissioned rail infrastructure. As railroad systems age or are modernized, materials such as steel rails, steel ties, iron components, and copper wiring become available for recycling. This process transforms potential waste into valuable resources that can be reintroduced into manufacturing.

The practice is a cornerstone of sustainability in the transportation sector. A mile of railroad track yields approximately 90 tons of recyclable steel. These high-grade metals retain their structural properties through multiple recycling cycles, making them particularly valuable in the circular economy.

Railway recycling offers dual benefits: substantial environmental advantages alongside clear financial incentives. Companies involved in rail maintenance and demolition can offset project costs through material recovery while contributing to resource conservation. The process requires specialized equipment and expertise to safely dismantle, sort, and process these heavy, durable components for reuse.

What Are the Environmental Benefits of Recycling Railroad Scrap?

Recycling railroad scrap metal offers substantial environmental advantages beyond basic waste management. By diverting metal components from aging rail infrastructure to recycling facilities instead of landfills, we create a series of positive environmental outcomes beneficial to both current and future generations.

The environmental impact of recycling railroad scrap is significant due to the large volume of material involved. A single mile of railroad track can yield approximately 90 tons of recyclable steel, while replacing every mile generates about 400 tons. These quantities make railroad recycling especially valuable from an environmental perspective.

Waste Reduction and Landfill Diversion

One immediate benefit of recycling railroad scrap is the reduced waste sent to landfills. Railroad infrastructure contains numerous components that would otherwise take up valuable landfill space. Proper recycling ensures these materials remain in productive use instead of becoming environmental burdens.

Without recycling, discarded railroad materials could pose significant environmental hazards. Chemicals in treated railroad ties and other components can leach into soil and groundwater if improperly disposed of in landfills. Recycling prevents these harmful substances from contaminating natural systems.

- Landfill space conservation – Each ton of recycled railroad metal saves space in already crowded landfills

- Hazardous material containment – Proper recycling prevents harmful chemicals from contaminating soil and water

- Fire hazard reduction – Recycling eliminates fire risks associated with stockpiled railroad materials

Natural Resource Conservation

Recycling railroad scrap significantly reduces the need for virgin material extraction. The steel, iron, copper, and other metals recovered from railroad infrastructure decrease demand for new mining operations, which often cause substantial environmental disruption.

The resource conservation benefits are significant. A single locomotive contains enough steel to manufacture over 100 cars. By recycling these materials, we preserve natural landscapes that would otherwise be disrupted by mining activities.

- Reduced mining impacts – Less demand for raw materials means fewer extraction sites

- Habitat preservation – Natural ecosystems remain undisturbed when mining activity decreases

- Water resource protection – Minimized mining operations result in less water pollution and consumption

Energy Savings and Emissions Reduction

The energy required to recycle metal is substantially lower than what’s needed to extract and refine virgin materials. This energy efficiency directly reduces greenhouse gas emissions. The Environmental Protection Agency estimates that scrap metal recycling contributes to greenhouse gas reductions equivalent to removing 4.5 million cars from highways annually.

Railroad recycling contributes significantly to these carbon savings. Research shows that recycling one kilometer of railway track ballast saves approximately 52,211 kg of CO2 equivalent. TiEnergy LLC reported saving 1.6 million pounds of carbon in 2023 through environmentally friendly disposal methods for railroad ties alone.

- Lower carbon footprint – Producing recycled metal generates up to 58% less CO2 than virgin material production

- Energy conservation – Recycling aluminum saves up to 95% of the energy needed to produce new aluminum

- Air quality improvement – Fewer emissions mean cleaner air and reduced respiratory health risks

Circular Economy Support

Railroad scrap recycling exemplifies circular economy principles by transforming waste into valuable resources. The materials recovered become inputs for new manufacturing processes, creating a continuous cycle of use and reuse.

This circularity creates ripple effects throughout the economy. Recycled railroad materials find new life in construction projects, automotive manufacturing, and even new railroad infrastructure, completing the sustainability loop.

By promoting this circular approach, railroad recycling helps shift our economic model away from the traditional extract-use-discard pattern toward one that maximizes resource value and minimizes waste.

[[artifact_table]] Environmental Impact of Railroad Scrap Recycling vs. Virgin Metal Production [[/artifact_table]]How Does the Railway Scrap Recycling Process Work?

Railway scrap recycling follows a systematic approach designed to maximize resource recovery while ensuring environmental compliance. The process transforms decommissioned railroad materials into valuable resources for reuse in manufacturing. Each step requires specialized equipment and technical expertise to handle the challenges of railway infrastructure components.

1. Decommissioning and Removal

The recycling journey begins with the safe decommissioning of rail lines. Crews use specialized heavy machinery to carefully remove steel rails from the track bed, meticulously disconnecting all fasteners, spikes, and plates to avoid damaging other materials.

Modern rail-lifting equipment allows for the quick extraction of heavy rails while minimizing environmental disruption. During this phase, workers must follow strict safety protocols, given the weight and potential hazards of railway components.

Steel ties interspersed with wooden or composite ties are systematically removed and sorted. A single mile of railroad track can yield approximately 90 tons of recyclable steel, making this step crucial for resource recovery.

2. Sorting and Initial Processing

After removal, rails, ties, and associated hardware are transported to sorting facilities. Here, materials are separated by type: steel rails, steel ties, non-ferrous metals, and wooden or composite components.

Advanced sorting technologies, including magnetic separators and automated conveyor systems, enhance efficiency and material purity. Steel rails and ties are cut into standardized lengths for easier handling and transportation to recycling centers.

Workers address any hazardous coatings or residues, such as creosote from steel ties, to ensure compliance with environmental standards. This step prevents contamination and ensures the recovered materials meet quality requirements.

3. Cleaning and Shredding

At the recycling facility, sorted steel components undergo thorough cleaning to remove soil, ballast residue, and contaminants. Industrial shredders or crushers break down the rails and ties into smaller, manageable pieces.

Cleaning is essential for producing high-quality recycled metal. Non-metallic attachments are removed, and surface contaminants are eliminated using various cleaning methods.

Shredding increases the surface area of the metal pieces, making the subsequent melting process more energy-efficient. Different components may require specialized shredding equipment depending on their size, thickness, and composition.

4. Metal Melting and Recovery

The cleaned scrap steel enters energy-efficient electric arc furnaces, producing less pollution and greenhouse gas emissions than traditional steelmaking methods using virgin ore. During this process, non-metallic materials are separated, and the molten steel is poured into molds or cast into billets for new products.

Recovered fasteners and hardware are also melted down and reused, contributing to high recovery rates and supporting a robust circular economy. The melting process reaches temperatures high enough to burn off lingering impurities.

This phase consumes significant energy but still represents a 75% energy savings compared to producing new metals from virgin materials. The environmental benefits include reduced mining impacts and lower carbon emissions.

5. Quality Control and Distribution

Once refined and cast, the steel undergoes stringent quality control testing to ensure its purity and strength meet industry standards. Only after passing these tests is the metal certified for reuse in manufacturing, construction, or new railroad infrastructure.

The final recycled products are distributed to steel mills, fabricators, and manufacturers, completing the recycling loop and reducing the need for virgin material extraction. Nearly all components from decommissioned railroad lines find new life in future products.

Quality control may include chemical composition analysis, structural integrity testing, and verification of physical properties. These measures ensure the recycled metal meets the specifications for its intended applications.

6. E-Waste Component Processing

Modern railway systems contain significant electronic components that require specialized handling during recycling. Signal systems, monitoring equipment, and control mechanisms contain valuable materials, including copper, gold, silver, and rare earth elements.

E-waste processing involves the careful disassembly of electronic components, separation of circuit boards, and recovery of precious metals. These materials undergo specialized recycling streams to safely extract valuable elements while preventing environmental contamination.

The recovery of these materials not only provides economic value but also prevents potentially harmful substances from entering landfills. Proper handling of railway e-waste components is essential for environmental protection and resource conservation.

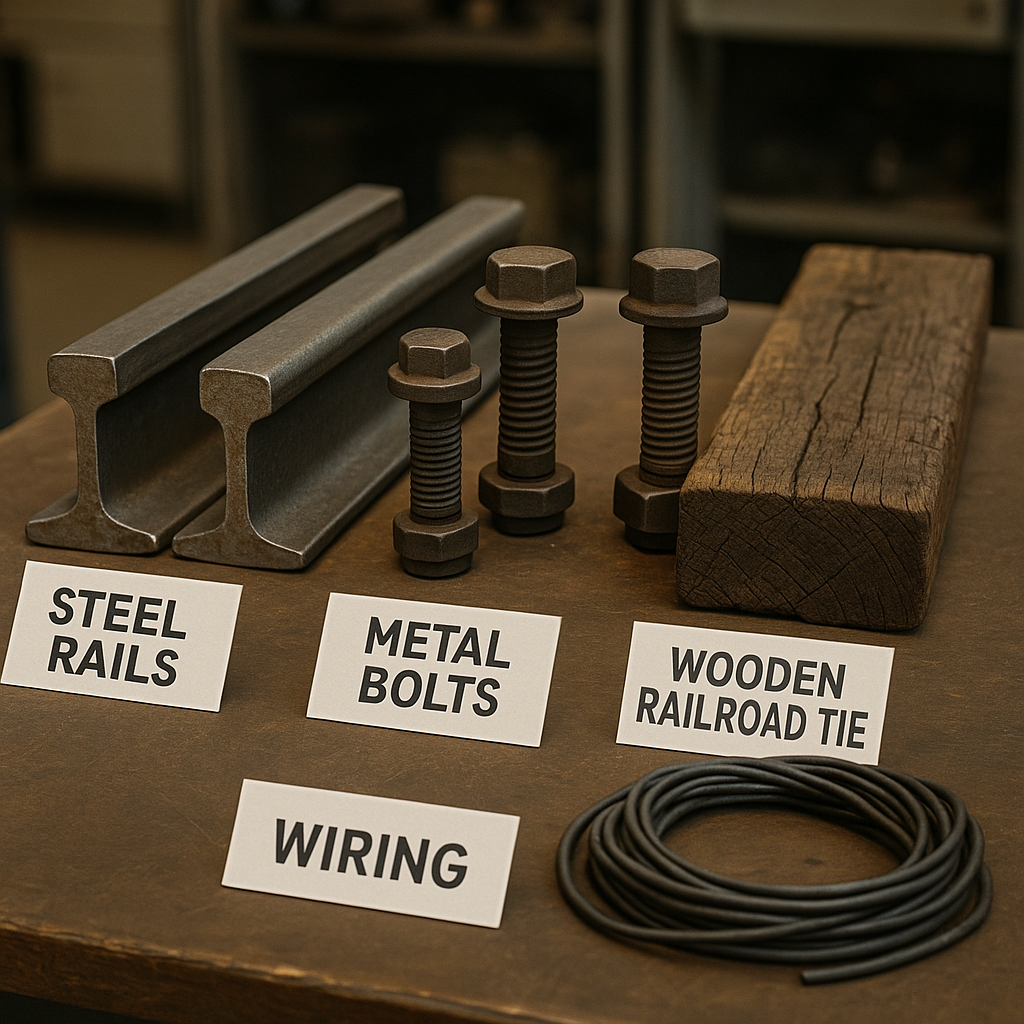

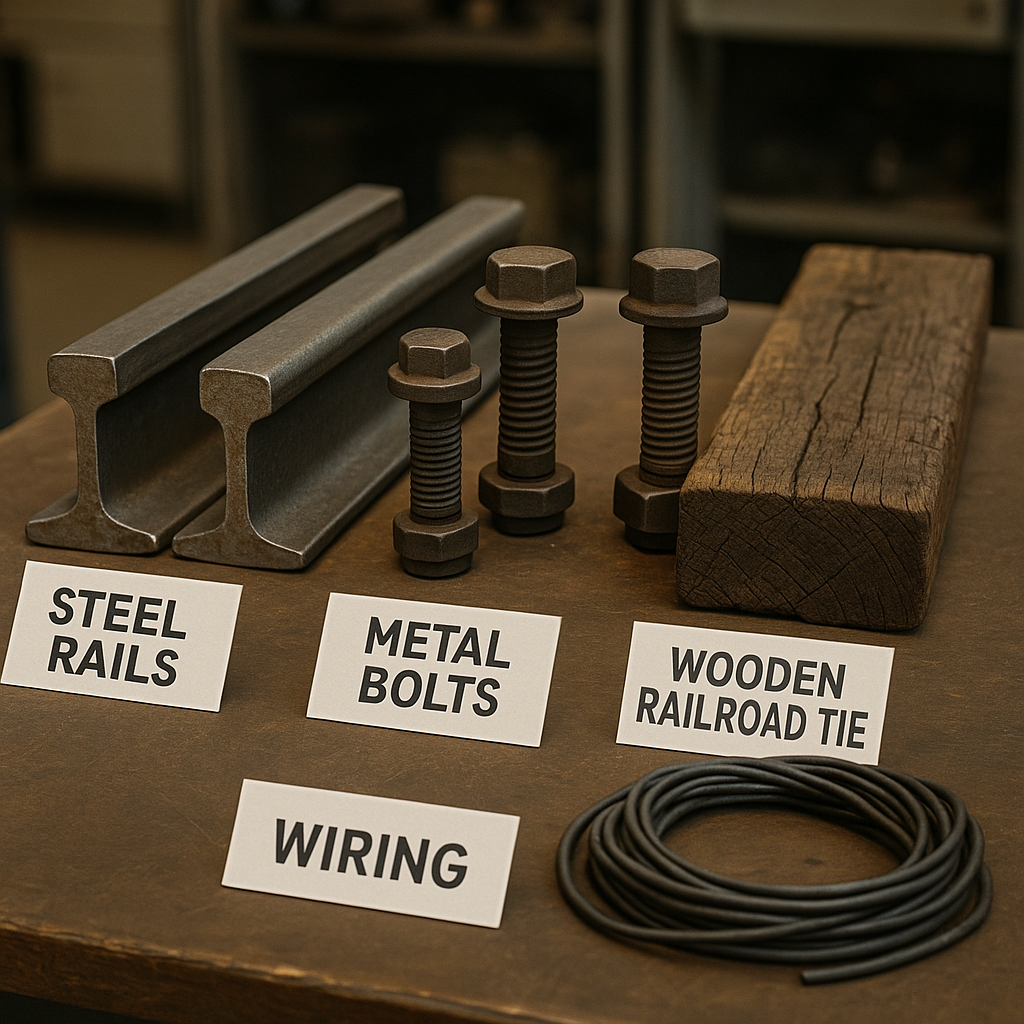

What Types of Materials Are Recycled from Railway Scrap?

Railway infrastructure contains valuable materials that can be recovered through recycling. Steel and iron from tracks, switches, and structural components represent the largest volume of recyclable materials from railway operations. These metals are processed and reintroduced into manufacturing, reducing the need for new mining.

Copper is another highly valuable metal recovered from railway systems. It is found extensively in electrical wiring, signaling equipment, and power transmission components. The high conductivity and durability of copper make it particularly valuable in the recycling market.

Electronic components from control panels, signaling systems, and networking equipment yield precious metals during recycling, including gold, silver, tungsten, and chromium. Specialized dismantling processes separate these materials to maximize recovery rates and value.

Railway operations rely heavily on battery systems for safety features like crossing guards and lighting systems. These batteries contain valuable materials, such as nickel, cobalt, copper, and lithium. As battery-powered train technology advances, the importance of proper battery recycling grows. Modern recycling facilities use specialized processes to safely handle the toxic chemicals in batteries while recovering these valuable metals.

Non-metallic materials from railway scrap are also processed appropriately. While many plastic and rubber components may not be as valuable as metals, proper sorting ensures these materials are either recycled when possible or disposed of safely to minimize environmental impact.

The recycling process typically involves multiple stages of sorting and separation. Materials undergo mechanical processing techniques after initial manual disassembly. This systematic approach ensures maximum recovery of valuable materials while properly managing potentially hazardous components.

Specialized recycling facilities provide both environmental and economic benefits through railway scrap recycling. By recovering these materials, they reduce the need for new raw material extraction while preventing potentially harmful substances from entering landfills. The metals recovered from railway scrap maintain their properties through recycling, making them ideal for reuse in new manufacturing applications.

Conclusion: The Future of Railway Scrap Recycling

Railway scrap recycling is fundamental to sustainable rail infrastructure management. The industry is steadily moving away from traditional take-make-waste models towards regenerative closed-loop systems that enhance resource efficiency and reduce environmental impact. This shift is not only an environmental initiative; it is a competitive necessity as sustainability increasingly drives innovation and economic value in transportation.

With the rail sector advancing through innovations like battery-powered trains and advanced materials, recycling processes must evolve in parallel. Cross-sector collaboration is becoming essential, with circular economy partnerships being established to optimize resource use throughout the rail ecosystem. The environmental benefits of this shift are significant: recycling reduces landfill waste, conserves natural resources, and lowers greenhouse gas emissions compared to producing new materials from raw ore.

For your railway scrap recycling needs, contact Okon Recycling at 214-717-4083. Our specialized services ensure your rail materials are processed efficiently, maximizing both environmental and economic value while supporting your sustainability goals.

Railway scrap metal recycling involves the systematic recovery and reprocessing of valuable metals from decommissioned rail infrastructure. As railroad systems age or are modernized, materials such as steel rails, steel ties, iron components, and copper wiring become available for recycling. This process transforms potential waste into valuable resources that can be reintroduced into manufacturing.

The practice is a cornerstone of sustainability in the transportation sector. A mile of railroad track yields approximately 90 tons of recyclable steel. These high-grade metals retain their structural properties through multiple recycling cycles, making them particularly valuable in the circular economy.

Railway recycling offers dual benefits: substantial environmental advantages alongside clear financial incentives. Companies involved in rail maintenance and demolition can offset project costs through material recovery while contributing to resource conservation. The process requires specialized equipment and expertise to safely dismantle, sort, and process these heavy, durable components for reuse.

What Are the Environmental Benefits of Recycling Railroad Scrap?

Recycling railroad scrap metal offers substantial environmental advantages beyond basic waste management. By diverting metal components from aging rail infrastructure to recycling facilities instead of landfills, we create a series of positive environmental outcomes beneficial to both current and future generations.

The environmental impact of recycling railroad scrap is significant due to the large volume of material involved. A single mile of railroad track can yield approximately 90 tons of recyclable steel, while replacing every mile generates about 400 tons. These quantities make railroad recycling especially valuable from an environmental perspective.

Waste Reduction and Landfill Diversion

One immediate benefit of recycling railroad scrap is the reduced waste sent to landfills. Railroad infrastructure contains numerous components that would otherwise take up valuable landfill space. Proper recycling ensures these materials remain in productive use instead of becoming environmental burdens.

Without recycling, discarded railroad materials could pose significant environmental hazards. Chemicals in treated railroad ties and other components can leach into soil and groundwater if improperly disposed of in landfills. Recycling prevents these harmful substances from contaminating natural systems.

- Landfill space conservation – Each ton of recycled railroad metal saves space in already crowded landfills

- Hazardous material containment – Proper recycling prevents harmful chemicals from contaminating soil and water

- Fire hazard reduction – Recycling eliminates fire risks associated with stockpiled railroad materials

Natural Resource Conservation

Recycling railroad scrap significantly reduces the need for virgin material extraction. The steel, iron, copper, and other metals recovered from railroad infrastructure decrease demand for new mining operations, which often cause substantial environmental disruption.

The resource conservation benefits are significant. A single locomotive contains enough steel to manufacture over 100 cars. By recycling these materials, we preserve natural landscapes that would otherwise be disrupted by mining activities.

- Reduced mining impacts – Less demand for raw materials means fewer extraction sites

- Habitat preservation – Natural ecosystems remain undisturbed when mining activity decreases

- Water resource protection – Minimized mining operations result in less water pollution and consumption

Energy Savings and Emissions Reduction

The energy required to recycle metal is substantially lower than what’s needed to extract and refine virgin materials. This energy efficiency directly reduces greenhouse gas emissions. The Environmental Protection Agency estimates that scrap metal recycling contributes to greenhouse gas reductions equivalent to removing 4.5 million cars from highways annually.

Railroad recycling contributes significantly to these carbon savings. Research shows that recycling one kilometer of railway track ballast saves approximately 52,211 kg of CO2 equivalent. TiEnergy LLC reported saving 1.6 million pounds of carbon in 2023 through environmentally friendly disposal methods for railroad ties alone.

- Lower carbon footprint – Producing recycled metal generates up to 58% less CO2 than virgin material production

- Energy conservation – Recycling aluminum saves up to 95% of the energy needed to produce new aluminum

- Air quality improvement – Fewer emissions mean cleaner air and reduced respiratory health risks

Circular Economy Support

Railroad scrap recycling exemplifies circular economy principles by transforming waste into valuable resources. The materials recovered become inputs for new manufacturing processes, creating a continuous cycle of use and reuse.

This circularity creates ripple effects throughout the economy. Recycled railroad materials find new life in construction projects, automotive manufacturing, and even new railroad infrastructure, completing the sustainability loop.

By promoting this circular approach, railroad recycling helps shift our economic model away from the traditional extract-use-discard pattern toward one that maximizes resource value and minimizes waste.

[[artifact_table]] Environmental Impact of Railroad Scrap Recycling vs. Virgin Metal Production [[/artifact_table]]How Does the Railway Scrap Recycling Process Work?

Railway scrap recycling follows a systematic approach designed to maximize resource recovery while ensuring environmental compliance. The process transforms decommissioned railroad materials into valuable resources for reuse in manufacturing. Each step requires specialized equipment and technical expertise to handle the challenges of railway infrastructure components.

1. Decommissioning and Removal

The recycling journey begins with the safe decommissioning of rail lines. Crews use specialized heavy machinery to carefully remove steel rails from the track bed, meticulously disconnecting all fasteners, spikes, and plates to avoid damaging other materials.

Modern rail-lifting equipment allows for the quick extraction of heavy rails while minimizing environmental disruption. During this phase, workers must follow strict safety protocols, given the weight and potential hazards of railway components.

Steel ties interspersed with wooden or composite ties are systematically removed and sorted. A single mile of railroad track can yield approximately 90 tons of recyclable steel, making this step crucial for resource recovery.

2. Sorting and Initial Processing

After removal, rails, ties, and associated hardware are transported to sorting facilities. Here, materials are separated by type: steel rails, steel ties, non-ferrous metals, and wooden or composite components.

Advanced sorting technologies, including magnetic separators and automated conveyor systems, enhance efficiency and material purity. Steel rails and ties are cut into standardized lengths for easier handling and transportation to recycling centers.

Workers address any hazardous coatings or residues, such as creosote from steel ties, to ensure compliance with environmental standards. This step prevents contamination and ensures the recovered materials meet quality requirements.

3. Cleaning and Shredding

At the recycling facility, sorted steel components undergo thorough cleaning to remove soil, ballast residue, and contaminants. Industrial shredders or crushers break down the rails and ties into smaller, manageable pieces.

Cleaning is essential for producing high-quality recycled metal. Non-metallic attachments are removed, and surface contaminants are eliminated using various cleaning methods.

Shredding increases the surface area of the metal pieces, making the subsequent melting process more energy-efficient. Different components may require specialized shredding equipment depending on their size, thickness, and composition.

4. Metal Melting and Recovery

The cleaned scrap steel enters energy-efficient electric arc furnaces, producing less pollution and greenhouse gas emissions than traditional steelmaking methods using virgin ore. During this process, non-metallic materials are separated, and the molten steel is poured into molds or cast into billets for new products.

Recovered fasteners and hardware are also melted down and reused, contributing to high recovery rates and supporting a robust circular economy. The melting process reaches temperatures high enough to burn off lingering impurities.

This phase consumes significant energy but still represents a 75% energy savings compared to producing new metals from virgin materials. The environmental benefits include reduced mining impacts and lower carbon emissions.

[[artifact_table]] Comparison of Railway Components and Their Recyclability [[/artifact_table]]5. Quality Control and Distribution

Once refined and cast, the steel undergoes stringent quality control testing to ensure its purity and strength meet industry standards. Only after passing these tests is the metal certified for reuse in manufacturing, construction, or new railroad infrastructure.

The final recycled products are distributed to steel mills, fabricators, and manufacturers, completing the recycling loop and reducing the need for virgin material extraction. Nearly all components from decommissioned railroad lines find new life in future products.

Quality control may include chemical composition analysis, structural integrity testing, and verification of physical properties. These measures ensure the recycled metal meets the specifications for its intended applications.

6. E-Waste Component Processing

Modern railway systems contain significant electronic components that require specialized handling during recycling. Signal systems, monitoring equipment, and control mechanisms contain valuable materials, including copper, gold, silver, and rare earth elements.

E-waste processing involves the careful disassembly of electronic components, separation of circuit boards, and recovery of precious metals. These materials undergo specialized recycling streams to safely extract valuable elements while preventing environmental contamination.

The recovery of these materials not only provides economic value but also prevents potentially harmful substances from entering landfills. Proper handling of railway e-waste components is essential for environmental protection and resource conservation.

What Types of Materials Are Recycled from Railway Scrap?

Railway infrastructure contains valuable materials that can be recovered through recycling. Steel and iron from tracks, switches, and structural components represent the largest volume of recyclable materials from railway operations. These metals are processed and reintroduced into manufacturing, reducing the need for new mining.

Copper is another highly valuable metal recovered from railway systems. It is found extensively in electrical wiring, signaling equipment, and power transmission components. The high conductivity and durability of copper make it particularly valuable in the recycling market.

Electronic components from control panels, signaling systems, and networking equipment yield precious metals during recycling, including gold, silver, tungsten, and chromium. Specialized dismantling processes separate these materials to maximize recovery rates and value.

Railway operations rely heavily on battery systems for safety features like crossing guards and lighting systems. These batteries contain valuable materials, such as nickel, cobalt, copper, and lithium. As battery-powered train technology advances, the importance of proper battery recycling grows. Modern recycling facilities use specialized processes to safely handle the toxic chemicals in batteries while recovering these valuable metals.

Non-metallic materials from railway scrap are also processed appropriately. While many plastic and rubber components may not be as valuable as metals, proper sorting ensures these materials are either recycled when possible or disposed of safely to minimize environmental impact.

The recycling process typically involves multiple stages of sorting and separation. Materials undergo mechanical processing techniques after initial manual disassembly. This systematic approach ensures maximum recovery of valuable materials while properly managing potentially hazardous components.

[[artifact_table]] Common Materials Recycled from Railway Scrap [[/artifact_table]]Specialized recycling facilities provide both environmental and economic benefits through railway scrap recycling. By recovering these materials, they reduce the need for new raw material extraction while preventing potentially harmful substances from entering landfills. The metals recovered from railway scrap maintain their properties through recycling, making them ideal for reuse in new manufacturing applications.

Conclusion: The Future of Railway Scrap Recycling

Railway scrap recycling is fundamental to sustainable rail infrastructure management. The industry is steadily moving away from traditional take-make-waste models towards regenerative closed-loop systems that enhance resource efficiency and reduce environmental impact. This shift is not only an environmental initiative; it is a competitive necessity as sustainability increasingly drives innovation and economic value in transportation.

With the rail sector advancing through innovations like battery-powered trains and advanced materials, recycling processes must evolve in parallel. Cross-sector collaboration is becoming essential, with circular economy partnerships being established to optimize resource use throughout the rail ecosystem. The environmental benefits of this shift are significant: recycling reduces landfill waste, conserves natural resources, and lowers greenhouse gas emissions compared to producing new materials from raw ore.

For your railway scrap recycling needs, contact Okon Recycling at 214-717-4083. Our specialized services ensure your rail materials are processed efficiently, maximizing both environmental and economic value while supporting your sustainability goals.