5901 Botham Jean Blvd, Dallas, TX 75215

What Are the Current Neodymium Magnet Scrap Prices?

September 3, 2025Neodymium magnet scrap currently trades at a wide range of prices, reflecting their crucial role in modern technology. Small neodymium magnets often sell for as little as $0.10 per unit. Medium-sized options typically fetch between $1 and $5 each, while larger or specialized magnets can command $10 or more depending on their condition and grade.

The foundation of all neodymium pricing begins with the raw material itself. According to recent market data, neodymium trades globally at approximately $68.05 per kilogram. This base price influences all aspects of the magnet market, from new production to scrap valuation.

The market has experienced remarkable volatility in recent years. Neodymium prices have fluctuated dramatically, with lows around $50 per kilogram and peaks near $140 per kilogram. These fluctuations directly affect what recyclers and scrap dealers will pay for used magnets.

What Factors Influence Neodymium Magnet Scrap Prices?

Raw material costs have a significant impact on neodymium magnet scrap prices, making up about 80% of the total cost. Neodymium magnets contain neodymium, praseodymium, dysprosium, and other rare earth elements, which constitute about 29-32.5% of the magnet’s weight. With current global neodymium prices around US$68.05/KG, these materials form the foundation on which other pricing factors build.

The grade of the magnet is another key factor. NdFeB magnets are classified into series from N30 through N52, with higher numbers indicating stronger magnetic properties. Higher-grade magnets are more expensive because they require precise manufacturing processes and typically contain larger amounts of costly rare earth elements. For instance, an N52 grade magnet usually costs 20-30% more than an N35 grade of the same size.

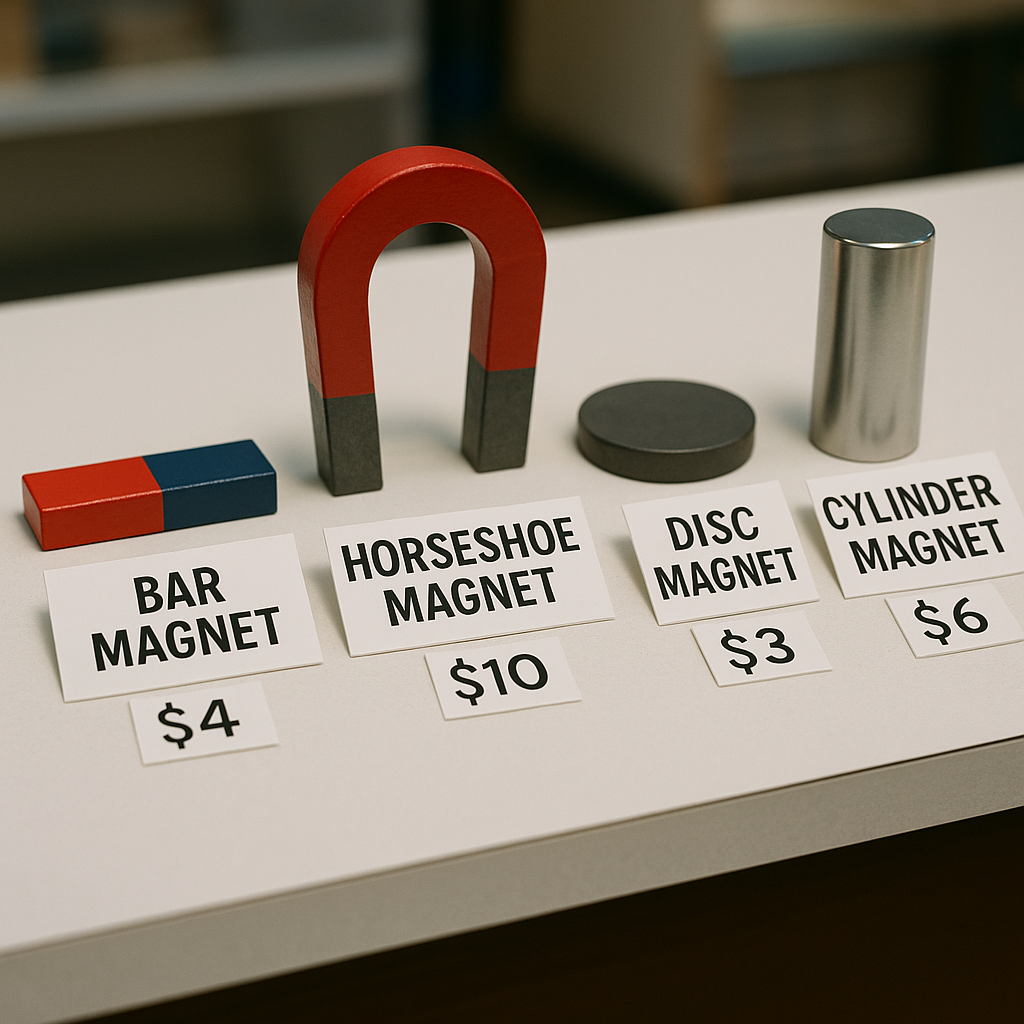

Size and shape complexity also influence price variations in the scrap market. Standard shapes like blocks, discs, and cylinders are more cost-effective to recycle. However, specialized configurations such as arc segments for motors or thin rings require more processing during recycling, increasing handling costs by 40-50% compared to simpler shapes.

Manufacturing processes add another layer to the pricing structure. Sintered NdFeB magnets—the strongest commercial type—require specialized equipment and precise temperature control during production. These quality differences persist in scrap value, as higher-quality manufactured magnets often contain more valuable materials. Surface treatments like nickel, zinc, or epoxy coatings also influence the recycling process, potentially affecting the final value.

Market volume and economic conditions can cause significant volatility in neodymium magnet scrap pricing. With China producing over 80% of the world’s rare earth elements, global prices are sensitive to policy changes or export restrictions from Chinese authorities. This concentration of supply contributes to market instability.

Global demand changes, especially from expanding sectors like electric vehicles and wind turbines, can rapidly alter availability and pricing throughout the supply chain. When demand increases, scrap prices typically rise as manufacturers look for alternative material sources. Conversely, economic downturns can result in price drops as demand for recycled materials falls.

Industry trends show that magnet scrap with known compositions and minimal contamination commands higher prices. Small neodymium magnet scraps typically start at $0.75 per pound, while larger rare-earth magnet pieces can range from $1.00 to $4.50 per pound, reflecting their grade, composition, and current market conditions.

How Do Neodymium Magnet Prices Compare to Other Types?

Neodymium magnets are among the most cost-effective options in the permanent magnet market. A typical neodymium disc magnet ranges from $0.10 to $10, making them accessible for both industrial applications and smaller projects. In contrast, samarium cobalt magnets carry a significantly higher price tag, with block magnets costing from $1 to over $100, depending on their size and specifications.

This substantial price difference arises primarily from raw material availability. Neodymium magnets consist of neodymium, iron, and boron—elements that are relatively abundant in the Earth’s crust. These materials contribute to lower production costs and greater accessibility in the market. On the other hand, samarium cobalt magnets require rarer elements, like samarium and cobalt, which are less abundant and more expensive to source.

Manufacturing complexity also plays a critical role in this price disparity. Producing samarium cobalt magnets involves more sophisticated techniques and higher-temperature sintering processes. These magnets demand precise control during manufacturing, increasing overall production costs compared to neodymium alternatives.

Market dynamics further widen the price gap between these two types of magnets. Neodymium magnets have gained widespread popularity across various industries, leading to larger production volumes and economies of scale. This has helped drive down their costs. Samarium cobalt magnets, primarily used in specialized applications, have a smaller market demand and lower production volume, contributing to their premium pricing.

Despite the higher cost, samarium cobalt magnets offer superior performance characteristics that justify their price for specific applications. They maintain magnetic strength at much higher temperatures—up to 350°C, compared to neodymium’s 80-200°C range. They also provide better corrosion resistance without needing protective coatings. In high-temperature industrial settings or corrosive environments, the performance advantages of samarium cobalt magnets often outweigh their higher initial cost.

Where Are Neodymium Magnets Commonly Used?

Neodymium magnets power countless devices and systems across multiple industries. Their exceptional strength-to-size ratio makes them indispensable in modern technology and sustainable energy solutions.

Consumer Electronics

Neodymium magnets are integral to various household devices. They’re essential in smartphones, enabling vibration and speaker functions. Laptops use these powerful magnets in their hard drives to position read/write heads precisely.

Audio equipment heavily depends on neodymium technology. High-quality headphones use these magnets to create powerful drivers for superior sound while maintaining a lightweight design. Neodymium magnets in speakers convert electrical signals into sound waves, regardless of size.

The trend toward miniaturization in consumer electronics relies on neodymium magnets. Their capacity to maintain strong magnetic fields despite their small size allows manufacturers to create compact yet powerful devices.

Industrial and Scientific Applications

The medical field extensively utilizes neodymium magnets in MRI machines. These diagnostic tools rely on powerful magnetic fields for detailed imaging of internal structures. The strength and stability of neodymium magnets make them ideal for this critical application.

Manufacturing processes frequently employ these magnets in magnetic separation systems. These setups remove unwanted ferrous materials from production lines, ensuring product quality and equipment protection. Lifting machinery also benefits from neodymium magnets, securely holding heavy metal objects during transport.

Scientific research equipment often incorporates neodymium magnets in specialized instruments. Their precise magnetic fields enable accurate measurements and consistent experimental conditions across various disciplines.

Green Energy and Automotive Technology

The renewable energy sector relies heavily on neodymium magnets. Wind turbines use these magnets in their generators to convert wind energy into electricity. A single large wind turbine can contain hundreds of pounds of neodymium magnets in its generator assembly.

Electric and hybrid vehicles represent another major application. These vehicles use neodymium magnets in their electric motors and generators. The magnets help create the magnetic fields necessary for efficient energy conversion, contributing to better range and performance.

Automotive safety systems also incorporate these magnets. ABS sensors use neodymium magnets to monitor wheel speed and prevent locking during braking. Other sensor systems throughout modern vehicles rely on these magnets for precise operation.

Emerging Technologies

The demand for neodymium magnets continues to grow with new technological developments. Magnetic refrigeration promises more energy-efficient cooling without harmful refrigerants.

Magnetic levitation transport systems use neodymium magnets for frictionless movement, offering potential high-speed, energy-efficient transportation options.

As technology advances, applications for these powerful magnets will likely expand into new areas. Their unique properties make them valuable components in the ongoing push for more efficient and sustainable technologies.

Conclusion: Understanding the Neodymium Magnet Scrap Market

The neodymium magnet scrap market functions within a complex ecosystem influenced by various economic factors. Costs of raw materials, manufacturing, and changing global demand all contribute to the market’s price volatility. Prices in this specialized market can vary greatly, ranging from cents to hundreds of dollars per unit, depending on factors like size, grade, purity, and current market conditions.

As demand grows in key sectors such as renewable energy and electric vehicles, tracking price dynamics in the neodymium scrap market has become increasingly important. The market has seen significant fluctuations, with neodymium prices experiencing substantial volatility. Recent years have witnessed dramatic shifts, including a 43% increase since early 2025 and a 34% decrease since January 2023. These changes reflect the market’s sensitivity to global supply chain challenges, geopolitical tensions, and industrial demand patterns.

For organizations involved in neodymium magnet recycling and recovery, staying informed about market trends is crucial for making profitable decisions.

Contact Okon Recycling at 214-717-4083 for professional guidance on recycling your neodymium magnet scrap.