5901 Botham Jean Blvd, Dallas, TX 75215

Electronic Waste Recycling: Steps, Benefits, and How You Can Participate

August 24, 2025Electronic waste, or e-waste, is among the fastest-growing waste streams worldwide. From old smartphones and computers to televisions and household electronics, millions of tons of discarded devices are generated each year. If not properly disposed of, these items can release hazardous materials like lead, mercury, and cadmium into the environment, contaminating soil and water sources.

However, e-waste also contains valuable resources such as copper, aluminum, and even precious metals like gold and silver—materials that can be reclaimed and reused in new manufacturing.

E-waste recycling addresses this issue by ensuring harmful components are handled safely while valuable resources are recovered. By understanding how the process works, both individuals and businesses can make informed decisions that reduce environmental harm and promote resource efficiency.

The E-Waste Recycling Process

The e-waste recycling process follows several stages that efficiently extract valuable components while safely managing hazardous materials. Each phase requires specialized equipment and trained personnel to ensure proper handling of electronic waste.

Collection

The recycling journey starts with gathering discarded electronics through designated collection points, drop-off centers, or take-back programs. Many municipalities and private organizations offer specialized e-waste collection services to prevent electronic devices from ending up in landfills.

Once collected, e-waste is carefully transported to recycling facilities where it’s stored safely until processing begins. Proper storage prevents leakage of toxic substances like lead or mercury that could harm the environment.

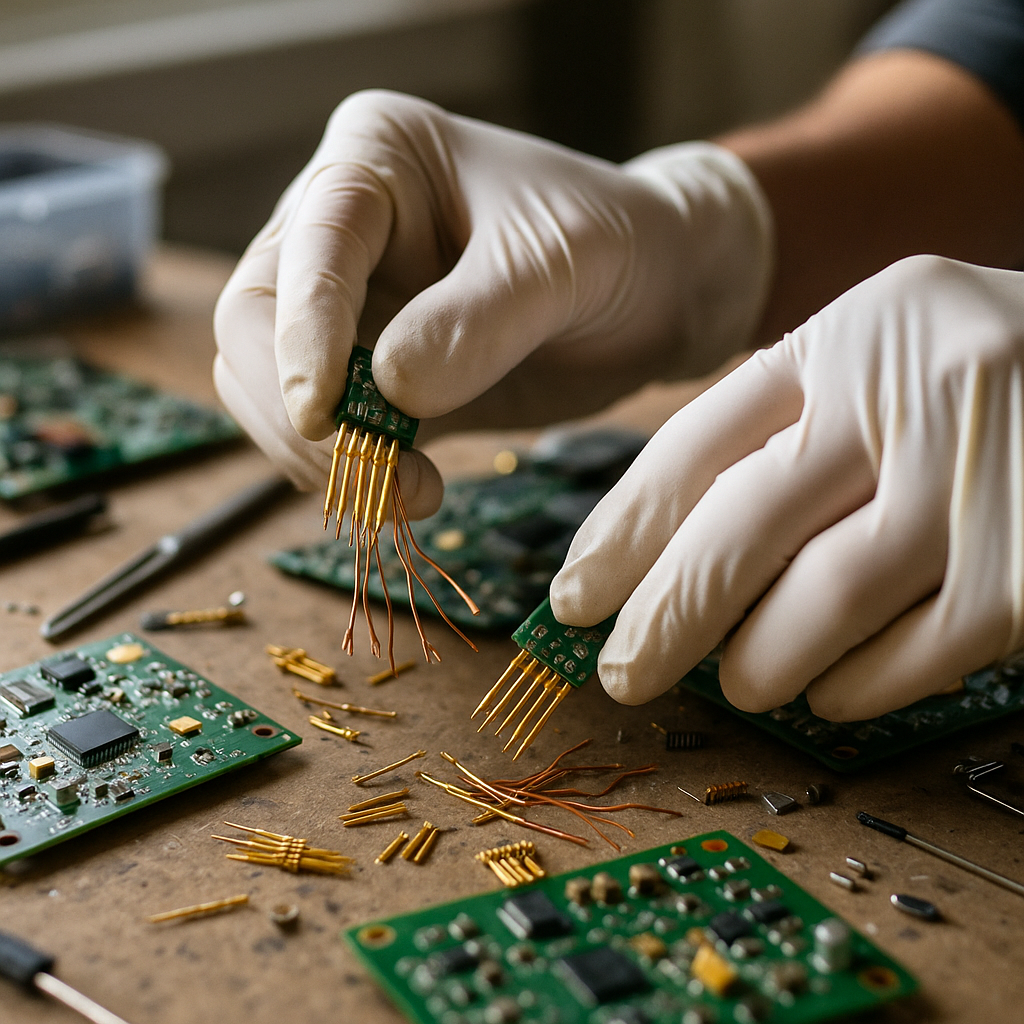

Manual Sorting and Dismantling

Skilled workers sort incoming e-waste by type and condition. They identify potentially reusable components and remove hazardous elements that require special handling. This phase, called de-manufacturing, is crucial for removing flammable materials like printer toner that could damage equipment during later processing stages.

Technicians disassemble devices to separate parts that can be refurbished or sold as replacement components. Items like circuit boards, processors, and memory chips often retain value even when the original device is obsolete. The remaining materials proceed to the mechanical processing stage.

Shredding

After manual dismantling, the remaining e-waste enters industrial shredders that break everything down into small pieces. These powerful machines transform bulky devices into fragments typically just a few centimeters in size. Shredding creates a homogeneous mixture that makes material separation more efficient in subsequent steps.

The shredding process must be carefully controlled to prevent dust emissions and manage heat generation. Modern facilities use enclosed systems with air filtration to capture particulates that might otherwise be released into the environment.

Material Separation

Once shredded, the e-waste undergoes sophisticated separation techniques to recover different materials:

Magnetic separation uses powerful magnets to extract ferromagnetic materials like iron and steel from the mixture. These metals are easily pulled out of the stream for recycling. Next, eddy current separators use alternating magnetic fields to separate non-ferrous metals like aluminum and copper, which are bounced away from other materials.

Water separation techniques then sort the remaining materials by density. Heavier items like glass sink to the bottom, while lighter materials like plastics float to the top. This allows for further refinement of the material streams before final processing.

Material Recovery and Refinement

The final stage involves processing the separated materials to prepare them for reuse. Metals undergo smelting to remove impurities, while plastics may be melted down and reformed into pellets. Glass is cleaned and processed for use in new products.

Currently, about ten chemical elements are commonly recovered from e-waste through mechanical processing, including gold, silver, platinum, cobalt, tin, copper, iron, aluminum, and lead. However, recovery technologies continue to improve, allowing for the extraction of additional valuable materials.

Challenges in E-Waste Recycling

Despite its benefits, e-waste recycling faces several challenges. Modern electronics are becoming smaller and more integrated, making disassembly difficult. Many devices now have permanently attached batteries or glued components, complicating recycling efforts.

Additionally, out of approximately 60 chemical elements present in e-waste, current mechanical processes can only effectively recover about 10. This limitation presents both a challenge and an opportunity for technological advancement in the recycling industry.

E-waste recycling not only prevents toxic substances from contaminating our environment but also reduces the need for raw material extraction. By recovering valuable materials from discarded electronics, the industry plays a vital role in building a more circular economy for electronic products.

What Materials Can Be Recovered from E-Waste?

E-waste is a concealed source of valuable materials ready to be reclaimed. Discarded electronics are far from mere trash; they contain a wide array of resources that can be reintroduced into the manufacturing supply chain.

The most noticeable materials in e-waste are precious metals. A single mobile phone contains approximately 0.034 grams of gold, 0.35 grams of silver, and small amounts of palladium and platinum. These metals serve as excellent conductors in electronic components, connectors, and circuit boards. Computer hard drives are also rich in these metals, with estimates suggesting that one ton of circuit boards contains 40-800 times the gold concentration found in mined gold ore.

Base metals are even more prevalent in discarded electronics. Aluminum constitutes 0.8-2% of wind turbines and 7-17.5% of solar panels, while copper, found in wiring and circuits, and tin, used in solder, are present in significant quantities. Nickel, which serves both structural and electrical purposes, can make up to 13.5% of some e-waste components.

Rare earth elements (REEs) such as neodymium, dysprosium, europium, terbium, and yttrium, are crucial for manufacturing high-tech devices but are often difficult and environmentally damaging to mine. Neodymium and dysprosium, for instance, are used in powerful magnets found in hard drives, speakers, and MRI machines. Each F-35 aircraft requires about 920 pounds of REEs for its advanced systems. Through recycling processes like those developed at Oak Ridge National Laboratory, over 97% of these elements can be recovered from e-waste.

Other materials include indium from LCD screens, gallium from semiconductors, and tantalum from capacitors. Plastics and glass also make up a considerable portion of e-waste by volume and can be recovered and repurposed.

How Can Individuals and Businesses Participate in E-Waste Recycling?

Due to the increasing environmental impact of electronic waste, the involvement of both individuals and businesses is crucial. The EPA estimates that recycling one million laptops saves enough energy to power over 3,500 U.S. homes for a year, underscoring the importance of effective e-waste management.

Options for Individual Consumers

Consumers have several convenient ways to responsibly dispose of electronic waste. Authorized collection points are accessible options for many, with retailers and manufacturers often offering drop-off locations where devices can be left at no cost.

Community collection events provide excellent opportunities for responsible disposal. These events are held several times a year and accept a wide range of items. Checking with local environmental agencies or municipal websites can help consumers stay informed about upcoming events.

Mail-back programs offer convenience for those unable to reach physical drop-off points. Many manufacturers provide prepaid shipping labels and packaging, making this a simple and cost-effective option, particularly for consumers in rural areas with limited recycling infrastructure.

Business Participation Strategies

Businesses encounter unique challenges and opportunities in managing electronic waste. Implementing comprehensive disposal policies is key to effective corporate e-waste management, detailing procedures for identifying, collecting, and processing obsolete equipment while ensuring data security.

Partnering with certified e-waste recyclers gives businesses reliable, eco-friendly disposal options. Recyclers with certifications like e-Stewards or R2 (Responsible Recycling) follow stringent standards for safe and ethical processing of e-waste. These partnerships help businesses meet regulatory requirements while demonstrating environmental commitment.

Employee education programs can significantly boost participation rates. When staff understand the importance of proper disposal and the procedures involved, compliance improves markedly. Regular training sessions and clear communication about on-site collection points help maintain awareness.

The Role of Extended Producer Responsibility

Extended Producer Responsibility (EPR) programs task manufacturers with managing their products throughout their entire lifecycle. These programs encourage the design of more recyclable and eco-friendly electronics from the outset. Through EPR initiatives, manufacturers set up take-back programs to accept end-of-life devices for proper recycling.

Consumer support for companies with robust EPR programs can drive industry-wide improvements. By opting for products from manufacturers with established recycling programs, consumers can influence corporate behavior and promote sustainable practices across the electronics industry.

Best Practices for E-Waste Recycling

Data security is a primary concern when recycling electronic devices. Both individuals and businesses should ensure complete data removal before disposal. For businesses, this might involve partnering with recyclers that offer certified data destruction services, adhering to standards like NIST 800-88 or DoD 5220.22-M.

Understanding what qualifies as e-waste helps ensure proper disposal. Common items include computers, monitors, TVs, mobile phones, printers, and small household electronics. Some jurisdictions have specific definitions and requirements for electronic waste.

Researching before recycling ensures items reach responsible handlers. R2 certification and e-Stewards certification indicate recyclers that adhere to rigorous environmental and social standards, helping consumers and businesses identify trustworthy partners.

Overcoming Common Barriers

Convenience is crucial for participation rates. If recycling is difficult or time-consuming, many resort to improper disposal methods. Manufacturers and recyclers can address this by increasing collection points and simplifying the process.

Awareness of e-waste’s environmental impact motivates better disposal practices. Educational campaigns that highlight the hazardous materials in electronics and their potential environmental harm can increase recycling program participation.

Financial incentives can significantly boost participation. Trade-in programs, recycling rebates, and deposit systems offer tangible benefits for proper disposal, especially for high-value items like smartphones and computers.

By implementing these strategies, individuals and businesses alike can contribute meaningfully to tackling the e-waste challenge. Their efforts not only reduce environmental harm but also recover valuable materials and promote a more sustainable approach to electronics consumption.

Conclusion: The Future of E-Waste Recycling

The escalating issue of electronic waste is among the most significant environmental challenges today. With global e-waste expected to reach 54 to 74 million metric tons annually by 2030, effective recycling solutions have become critically important. The future of e-waste recycling depends on technological innovation, regulatory frameworks, and collective action.

Proper e-waste management offers substantial benefits beyond environmental preservation, as we have explored throughout this article. Recovering valuable metals like gold, silver, and copper not only provides economic opportunities but also reduces the need for harmful mining practices. Advanced technologies such as AI-driven sorting systems, plasma arc recycling, and urban mining are transforming discarded electronics into valuable resources, embodying circular economy principles. By responsibly recycling your electronic devices, you contribute to this positive change and help shield our environment from toxic contamination. For professional e-waste recycling services that safely and sustainably process electronics, contact Okon Recycling at 214-717-4083.