5901 Botham Jean Blvd, Dallas, TX 75215

Exploring the Growing Need to Recover Rare Earth Metals from Electronics

August 17, 2025Nearly 90% of the world’s refined rare earth elements are produced in China. This supply concentration poses significant security risks for industries reliant on these crucial materials. Modern electronics—from smartphones to wind turbines—depend on rare earth metals for their unique magnetic, optical, and electrical properties.

The environmental cost of traditional rare earth mining is staggering. For each ton of rare earth elements extracted, up to 2,000 tons of toxic waste is produced. This process involves extensive land disruption and chemical leaching, and even generates radioactive byproducts that require careful disposal.

As global demand for electronics and clean energy technologies continues to grow, recycling rare earth metals from discarded devices offers a promising alternative to new mining. Electronics recycling not only reduces environmental impact but also strengthens domestic supply chains in North America, where reliance on foreign sources is an increasing concern.

What Are Rare Earth Metals and Where Are They Found in Electronics?

Rare earth metals comprise a group of 17 elements in the periodic table with exceptional magnetic and electrochemical properties. Despite their name, these elements aren’t particularly rare in the Earth’s crust. The real challenge is their dispersed nature, which makes economical extraction and processing difficult.

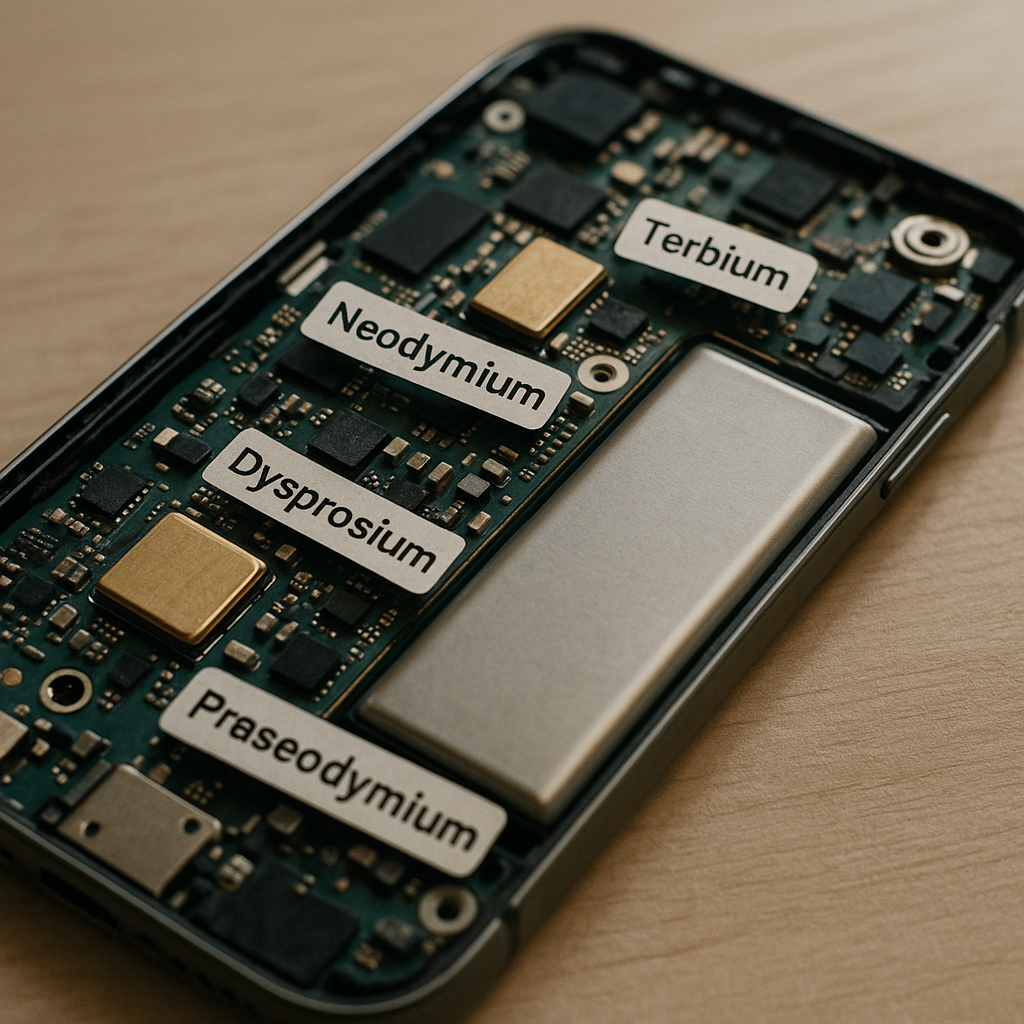

These elements play a critical role in modern electronics, powering everything from the device in your pocket to the screen on your desk. Their unique properties enable the miniaturization and enhanced performance we expect from our technology.

Key Components Powered by Rare Earth Elements

In the world of displays and lighting, rare earth elements are indispensable. Yttrium, europium, and terbium create the red-green-blue phosphors used in screens ranging from smartphone displays to stadium scoreboards. Digital camera lenses, including those in cell phones, contain up to 50 percent lanthanum.

Magnets represent one of the fastest-growing applications for these materials. Neodymium-iron-boron magnets—the strongest known magnets—are essential where space and weight are limited. They power computer hard disks, DVD drives, and stabilize spinning components.

Battery technology, particularly for electric vehicles, relies heavily on these elements. Nickel-metal hydride batteries use lanthanum-based alloys as anodes, with hybrid electric cars requiring 10-15 kilograms of lanthanum per vehicle.

Beyond these visible applications, rare earth metals function behind the scenes in many devices. Lanthanum catalysts help refine petroleum products, while cerium-based catalysts are crucial in automotive catalytic converters. In manufacturing, elements like cerium, lanthanum, neodymium, and praseodymium remove impurities in steel production and create special alloys.

The glass industry is the largest consumer of rare earth raw materials. These elements provide color and special optical properties to glass and serve as polishing agents, affecting virtually every screen-based device in modern homes and offices.

Why is Recycling Rare Earth Metals from Electronics Important?

Recycling rare earth metals from electronics helps reduce the environmental damage caused by traditional mining operations. Extracting these elements typically involves significant land disruption, chemical processing, and waste generation, which can contaminate soil and water sources.

Conserving finite resources is another critical benefit. Although rare earth metals are not necessarily scarce, they are dispersed in small concentrations, making them challenging and costly to extract from natural deposits.

Current recycling rates present a sobering reality. Only about 1% of rare earth metals in discarded electronics are currently recovered for reuse. This extremely low rate represents a massive untapped resource sitting in landfills worldwide.

Supply Chain Resilience

Recycling creates a more stable supply chain for manufacturers who depend on these materials. As demand for electronics continues to grow, manufacturers face increasing pressure to secure reliable sources of rare earth metals.

The recycling process offers a domestic source of these critical materials, reducing dependence on foreign suppliers. This is particularly important considering that over 80% of rare earth metal production is currently concentrated in a single country.

Price volatility is another significant challenge for electronics manufacturers. Historical fluctuations in rare earth metal prices have sometimes exceeded 600% in a single year due to export restrictions and supply uncertainties.

Economic and Strategic Benefits

The economic case for rare earth recycling continues to strengthen as technologies improve. New extraction methods using specialized chemical processes can now recover these elements more efficiently from circuit boards and other electronic components.

Beyond immediate economic benefits, rare earth recycling addresses strategic concerns about resource security. Nations with limited natural deposits can develop recycling capacity to reduce vulnerability to supply disruptions.

Urban mining—the practice of recovering materials from discarded products—is a growing opportunity. A ton of recycled electronics can yield more rare earth metals than a ton of ore from traditional mining operations, while requiring significantly less energy.

Challenges in Implementation

Despite its importance, rare earth recycling faces several obstacles. The complex design of modern electronics makes disassembly and material separation technically challenging and labor-intensive.

The economic viability of recycling operations depends heavily on the market value of recovered materials. When prices fall below certain thresholds, recycling becomes less financially sustainable without policy support.

Collection infrastructure remains underdeveloped in many regions. Without efficient systems to gather end-of-life electronics, valuable materials continue to be lost to landfills or exported to countries with less stringent environmental regulations.

What Are the Challenges in Recovering Rare Earth Metals from Electronics?

Extracting rare earth metals from electronics presents several technical hurdles. These valuable elements are rarely found in pure form within devices; instead, they’re typically mixed with other metals or embedded in complex components, making separation difficult.

A major challenge is the low concentration of these metals. Most electronic devices contain only trace amounts of rare earth metals. A single smartphone features nearly all 17 rare earth elements, but each in minimal quantities. When considering the 1.16 billion smartphones produced globally in 2023, the collective value is significant yet remains difficult to capture efficiently.

Complex and Hazardous Extraction Processes

Current recycling methods for rare earth recovery often depend on aggressive chemical processes. These techniques require hazardous solvents and acids to separate the elements from surrounding materials. The environmental risks of these chemicals create additional containment and safety challenges.

The energy requirements present another significant barrier. Processing e-waste to extract rare earth metals demands substantial energy. The high temperatures needed for melting and refining these metals add to both the environmental footprint and operational costs of recycling operations.

Economic viability remains questionable under current methods. The complex processes, specialized equipment, and high energy costs often make rare earth recycling more expensive than primary mining, discouraging investment in recycling infrastructure despite environmental benefits.

Collection and Supply Chain Issues

The fragmented nature of e-waste collection systems creates significant inefficiencies. Unlike aluminum cans or paper products, electronics containing rare earths don’t have standardized collection channels in many regions, leading to low recovery rates and lost recycling opportunities.

Consumer awareness presents another hurdle. Many people lack knowledge about the value of rare earth elements in their devices or proper disposal methods. This knowledge gap results in valuable materials ending up in landfills instead of recycling streams.

The logistics of e-waste collection add further complications. Electronics come in various shapes, sizes, and compositions, making it challenging to establish efficient collection and sorting systems — especially when identifying and separately processing specific rare earth-containing components.

Market volatility also impacts recovery efforts. Fluctuating prices for rare earth metals can quickly change the economics of recycling operations. When prices drop, recycling becomes less profitable, potentially halting recovery efforts despite environmental needs.

Regulatory inconsistencies between regions create additional barriers. Some areas have advanced e-waste policies while others have minimal requirements. This patchwork approach leads to inefficiencies in the global recovery system and potential exploitation through illegal e-waste exports to regions with weaker environmental standards.

What New Technologies Are Being Developed for Rare Earth Recycling?

The recycling of rare earth elements is experiencing a technological transformation. Scientists are developing methods to extract these valuable materials with less environmental impact than traditional mining. The innovations range from microscopic helpers to robotic systems, addressing various challenges in the complex recovery of rare earths.

Bioleaching: Nature’s Mining Crew

Bioleaching uses bacteria to extract rare earth elements from discarded electronics and industrial waste. Specific microorganisms, like Gluconobacter, produce organic acids that can remove elements such as lanthanum and cerium from spent catalysts and fluorescent phosphors.

Unlike conventional extraction methods using harsh chemicals, these bacterial acids are biodegradable and less harmful to the environment. These microbes act as tiny mining crews, separating valuable elements at the molecular level without the destruction caused by traditional mining operations.

While current bacterial methods recover only 25-50% of rare earths compared to nearly 99% with hydrochloric acid, research suggests bioleaching can still be profitable. A 2019 study published in ACS Sustainable Chemistry & Engineering found that using agricultural waste instead of refined sugar to feed the bacteria could increase annual profits from $150,000 to about $650,000 for a plant recycling 19,000 metric tons of used catalyst yearly.

Copper Salt Extraction: A Greener Alternative

Another promising technology employs copper salts instead of acids to recover rare earths from discarded magnets. This method is valuable because neodymium-iron-boron magnets contain about 30% rare earth elements by weight and represent the largest application of these metals globally.

The process involves submerging shredded electronic waste in a copper salt solution at room temperature, dissolving the rare earths while allowing other metals to be recovered separately. The extracted rare earths are then solidified and transformed into powdered minerals called rare earth oxides.

This method achieves recovery rates of 90-98% and produces material pure enough for manufacturing new magnets. Moreover, it has a significantly lower environmental impact, with carbon emissions less than half those of conventional mining in China—about 50 kg of carbon dioxide equivalent per kilogram of rare earth oxide versus 110 kg.

Companies like TdVib in Iowa have licensed this technology and built pilot plants aiming to produce two tons of rare earth oxides monthly from recycled hard disk drives.

Robotic Dismantling Systems

Completing these advances are specialized robots designed to dismantle electronics and recover components containing rare earth elements. These automated systems can work with precision and consistency beyond human capability.

The robots identify and extract rare earth-containing parts, such as tiny motors, speakers, and vibration units, from discarded devices. This targeted recovery avoids the need to process entire devices, significantly reducing energy consumption and waste.

These robotic systems play a crucial role in making rare earth recycling more economically viable. By automating the labor-intensive dismantling process, they reduce costs while enhancing the purity of collected materials before chemical processing begins.

Mechanical Separation Innovations

Engineers are also developing mechanical processes that minimize or eliminate the need for chemical separation, using physical properties like density, magnetism, and size to sort and separate rare earth-containing components.

Advanced shredding and sorting technologies can accurately identify and isolate rare earth-rich fractions from electronic waste streams. Some systems use sensors and artificial intelligence to recognize components likely to contain valuable elements.

These mechanical approaches reduce the environmental impact of recycling by decreasing chemical usage. They also make recycling more accessible to regions without sophisticated chemical processing infrastructure.

Conclusion: The Future of Rare Earth Metal Recovery from Electronics

The recovery of rare earth metals from electronic waste is at a pivotal point. Advanced recycling technologies are transforming what was once considered unfeasible into an economically viable and environmentally necessary practice. Innovations in solvent extraction and urban mining techniques are gradually closing the loop in the electronics supply chain, making circular economy principles more achievable for these valuable materials.

As product design evolves to facilitate easier disassembly and collection systems become more efficient, significant improvements in recovery rates are anticipated. This progression is essential as global demand for these metals continues to rise. Those looking to implement responsible electronics recycling programs or learn more about sustainable rare earth metal recovery can contact Okon Recycling at 214-717-4083.