5901 Botham Jean Blvd, Dallas, TX 75215

The Power and Risks of Large Permanent Magnets

July 23, 2025A small neodymium magnet the size of a coin can lift objects weighing more than 1,000 times its own weight. This exceptional strength makes large permanent magnets invaluable across various industries. From medical equipment to renewable energy systems, these powerful magnets enhance innovation and efficiency.

However, this same power poses significant safety hazards. When two large neodymium magnets snap together unexpectedly, they can exert crushing force comparable to industrial machinery. This magnetic attraction occurs rapidly and over greater distances than expected. Such force can break the brittle magnet material, sending sharp fragments flying, or cause severe pinching injuries when fingers are caught between magnets.

Understanding proper handling protocols is crucial when working with these materials. Beyond physical injuries, large permanent magnets can damage sensitive electronics, erase data storage media, and interfere with medical devices like pacemakers. This article examines essential safety procedures to protect both handlers and equipment when dealing with these powerful but potentially hazardous tools.

What Personal Protective Equipment (PPE) Should Be Used?

Working with large magnets requires specific protective gear to prevent injuries. These powerful objects can pose serious hazards, from pinching skin to launching metal fragments at high speeds. The right PPE creates a critical safety barrier against potential dangers.

Safety goggles are essential when handling large magnets. Unlike standard eyewear, these goggles provide comprehensive protection against flying debris from shattering magnets. Neodymium magnets, in particular, are brittle and can break into sharp fragments upon collision.

Heavy-duty gloves serve multiple essential functions. They prevent painful pinching injuries when fingers get caught between attracting magnets and improve grip, reducing the chances of accidentally dropping a magnet. Opt for gloves with reinforced palms and fingers for maximum protection.

Protective clothing adds another layer of defense. Long sleeves and pants shield your skin if magnets snap together near your body. Regular work attire covering your limbs is sufficient, although thicker fabrics offer better protection against pinching.

Create a designated PPE area in your workstation for handling magnets, where workers can gear up before approaching the magnets. This simple organizational step reinforces safety protocols and ensures no one handles magnets without proper protection.

Remember, PPE effectiveness depends on consistent use. Even brief exposure without protection can lead to serious injuries, especially with larger, more powerful magnets that exert significant force across distances.

| PPE Type | Purpose | Details |

|---|---|---|

| Safety goggles | Eye protection | Protects against flying debris if magnets shatter. |

| Heavy-duty gloves | Hand protection | Prevents pinching injuries and enhances grip. |

| Protective clothing | Body protection | Shields skin from snapping magnets; regular clothing covering limbs is enough. |

For maximum safety, combine proper PPE with a clean workspace free of metal objects that could be inadvertently attracted to the magnets. Keep metal items, including tools, jewelry, and certain electronic devices, at a safe distance to prevent sudden, potentially dangerous movements towards the magnets.

How Should Large Magnets Be Handled Safely?

Large magnets present significant risks when mishandled. Their powerful magnetic fields can cause severe pinching injuries, damaged equipment, and even broken bones. Safe handling requires deliberate movements and proper precautions.

When working with large magnets, never allow them to slam together or approach each other rapidly. The magnetic attraction between powerful magnets can accelerate them with surprising force, creating a collision hazard that can damage the magnets and cause serious injury. Always move magnets slowly and deliberately, maintaining control throughout the handling process.

Non-magnetic spacers are essential safety tools when working with large magnets. Use wooden blocks, plastic wedges, or other non-ferrous materials to separate magnets during storage and handling. These spacers create a physical barrier that prevents unexpected attraction while giving you greater control over the magnetic forces at play.

One of the most dangerous mistakes when handling large magnets is allowing them to “jump” from a distance. Even a few inches of separation can result in magnets accelerating rapidly toward each other. This sudden movement often catches handlers by surprise, resulting in pinched fingers, broken magnets, or flying shards if the magnets collide and shatter.

Protective equipment is crucial when handling powerful magnets. Heavy-duty gloves reduce the risk of pinching injuries and improve your grip. Safety goggles protect your eyes from potential fragments if a brittle magnet breaks during handling. This basic protective gear can prevent serious injuries during routine magnet handling.

Keep large magnets away from electronic devices and storage media. The strong magnetic fields can corrupt data on hard drives, wipe credit cards, and damage sensitive equipment. Similarly, maintain a safe distance from individuals with medical implants like pacemakers or insulin pumps, as magnetic interference can cause these devices to malfunction.

Create a clean, organized workspace before handling large magnets. Remove all ferrous tools, loose metal objects, and unnecessary equipment from the area. A dedicated handling area with non-metallic surfaces further reduces the risk of unexpected magnetic attraction during handling procedures.

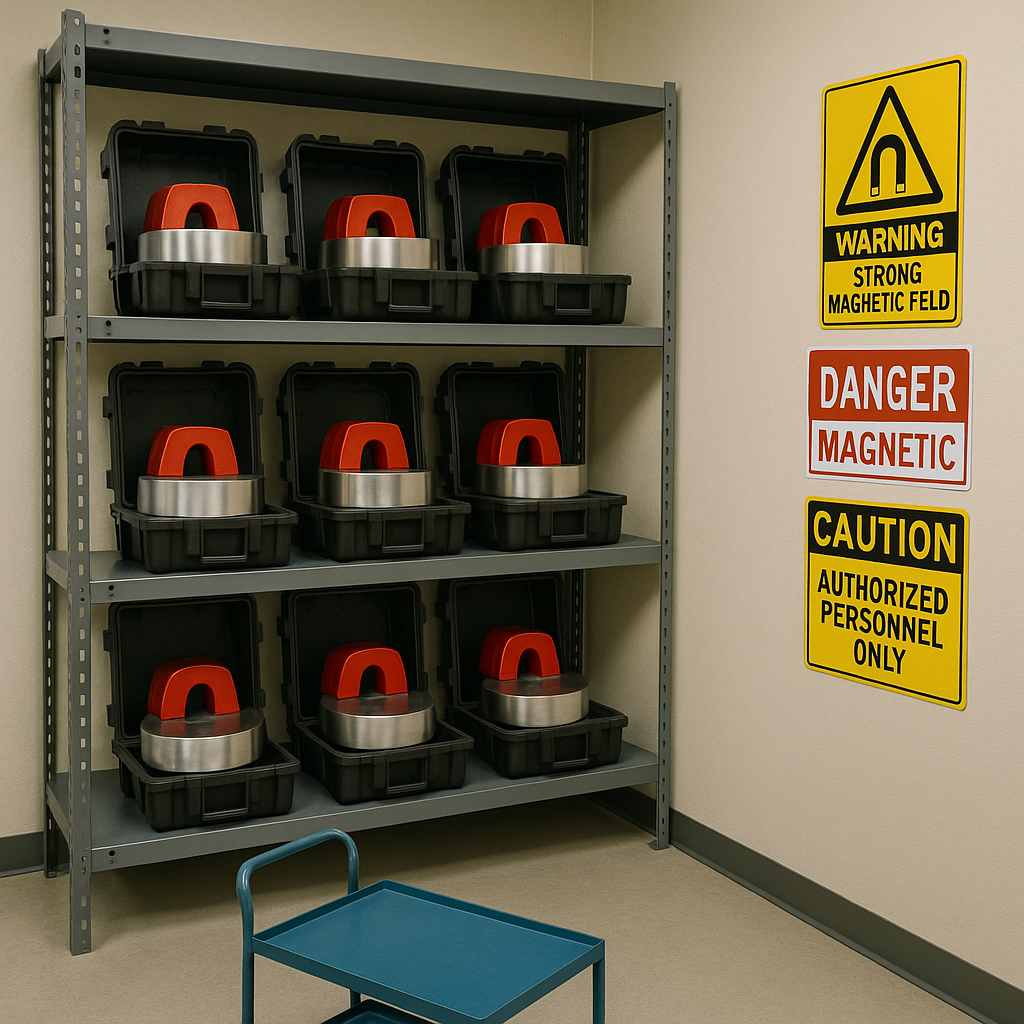

When storing large magnets, use keeper plates or original packaging whenever possible. These specialized storage solutions maintain proper separation and protect the magnets from physical damage. For long-term storage, clearly label magnetic materials and keep them in dedicated containers away from sensitive equipment.

| Protective Gear | Purpose |

| Safety Goggles | Protect eyes from flying debris |

| Heavy-Duty Gloves | Prevent pinching injuries and improve grip |

| Protective Clothing | Shield skin from snapping magnets |

| Non-Magnetic Spacers | Prevent unexpected attraction between magnets |

Remember that even experienced handlers must maintain respect for the power of large magnets. Their force doesn’t diminish over time, and familiarity should never lead to carelessness. By consistently following these safety protocols, you can work with large magnets effectively while minimizing the risks to yourself, your equipment, and those around you.

What Are the Best Practices for Magnet Storage and Transport?

Properly storing and transporting magnets is crucial for maintaining their strength and preventing damage or accidents. Industrial magnets, particularly neodymium magnets, require specific handling conditions to ensure they remain effective and safe.

Creating an Ideal Storage Environment

Store magnets in a clean, dry environment with humidity levels below 50%. This is essential because uncoated magnets, especially neodymium types, are highly susceptible to corrosion when exposed to moisture. Even small rust amounts can significantly reduce magnetic strength and compromise performance.

Temperature control is also vital. Keep magnets within 15-30°C (59-86°F) during storage. High temperatures can cause permanent demagnetization—neodymium magnets begin to lose magnetic properties when exposed to temperatures above 80°C (176°F). Some specialized magnets have even lower temperature thresholds.

Using Proper Storage Containers

Always use sturdy, non-ferrous containers for magnet storage. Plastic storage boxes, wooden crates, or aluminum containers work well because they won’t interact with the magnetic field. Avoid using cardboard for long-term storage as it can absorb moisture and contribute to corrosion problems.

For smaller magnets, consider using compartmentalized organizers with individual cells that prevent magnets from connecting. For larger industrial magnets, wooden racks with non-magnetic dividers provide excellent separation while maximizing storage space.

Implementing Separation Techniques

Keep magnets separated using appropriate spacers or keepers. Plastic, wood, or cardboard spacers between magnets prevent them from snapping together, which can cause chipping, cracking, or even shattering due to their brittle nature.

When storing multiple magnets, arrange them in an attracting orientation (north pole to south pole) with spacers between them. This configuration is more stable than storing magnets in a repelling orientation, which can shift unexpectedly.

Transport Safety Protocols

For transport, use containers with magnetic shielding properties. Steel boxes or containers with mu-metal lining can contain the magnetic field and prevent interference with navigation equipment or other sensitive devices. This is particularly important for air shipments where magnetic interference with aircraft navigation systems is a serious concern.

Be aware that air transportation of strong magnets is regulated. In the United States, magnetic materials with field strength greater than 0.00525 gauss at 15 feet are classified as hazardous materials (Class 9) for air transport under the Code of Federal Regulations (CFR) 49. Ground shipping is often preferred for powerful magnets to avoid these restrictions.

Clear Labeling and Documentation

Label all packages containing magnets clearly with warnings about magnetic contents. Use standard magnetic warning symbols and text indicating “CAUTION: MAGNETIC MATERIAL ENCLOSED.” This alerts handlers to take appropriate precautions and prevents packages from being placed near sensitive equipment.

For commercial shipments, include proper documentation that identifies the magnetic materials and their strength. This helps carriers assess any potential risks and handle the shipment appropriately.

Keeping Distance from Sensitive Items

Always maintain safe distances between stored or transported magnets and sensitive electronics, credit cards, hard drives, or medical devices. Even when properly packaged, strong magnets should be kept at least 30 cm (12 inches) away from items that could be damaged by magnetic fields.

For those working in environments with powerful magnets, establish designated storage areas that are clearly marked and located away from workstations with computers or electronic equipment.

| Magnet Type | Recommended Storage | Recommended Transport |

|---|---|---|

| Alnico | Keep dry; avoid humidity. | Protected from cold to avoid cracking. |

| Ceramic | Protect from cold temperatures. | Requires similar protection as Alnico. |

| Neodymium | Store in low-humidity, low-moisture environment near room temperature. | Use magnetic shielding materials (steel sheets or magnetic receptive foams). |

| Samarium Cobalt | Requires low humidity environments near room temperature. | Store in original wrapping with spacers to avoid attraction. |

Handling Techniques During Transfer

When moving magnets from storage to transport containers, use non-metallic tools like plastic wedges or wooden implements. These tools help separate magnets safely without risking injury to handlers or damage to the magnets.

For larger industrial magnets, wear protective gloves and eye protection. The sudden attraction between powerful magnets can cause serious pinching injuries or create flying chips if magnets collide and break.

By following these best practices for magnet storage and transport, you can maintain the integrity of your magnetic materials while ensuring the safety of personnel and equipment. Proper handling techniques not only extend the useful life of magnets but also prevent potentially dangerous situations that can arise from mishandling these powerful tools.

Conclusion: Prioritizing Safety in Magnet Handling

Handling large permanent magnets requires meticulous attention to safety protocols to prevent injuries and equipment damage. The powerful magnetic fields these magnets generate necessitate proper protective equipment, careful handling techniques, and suitable storage solutions. Pinching injuries, flying debris from broken magnets, and damage to electronic devices are real risks that must be mitigated through proper procedures.

Adhering to best practices—wearing PPE, using controlled movements, maintaining clean workspaces, and storing magnets appropriately—significantly reduces these hazards. Implementing thoughtful handling procedures protects personnel and preserves the integrity and performance of these valuable industrial tools. Prevention is always better than facing the consequences of improper handling when working with powerful magnets.

For your industrial recycling and magnet disposal needs, contact Okon Recycling at 214-717-4083. Our team can help you safely recycle magnetic materials and provide guidance on proper handling protocols for your specific requirements.